Do you still remember that dress that sparked global discussions? You were back then

“Platinum Party” or “Blue-Black Party”?

Human judgment of color is a very subjective feeling and is easily influenced

Manipulation is prone to cause visual errors. However, in many cases, precise facial features are requiredhttps://heiautomation.com/product/

In industrial scenarios involving color judgment, this kind of visual error cannot be ignored

In the food industry, the color of products not only affects consumers’ purchasing desire

It is also related to product quality and food safety standards. In chemical production

In the process, the color change of raw materials or products may reflect that the production process is

Is it normal? At this point, a professional and accurate color detector is needed

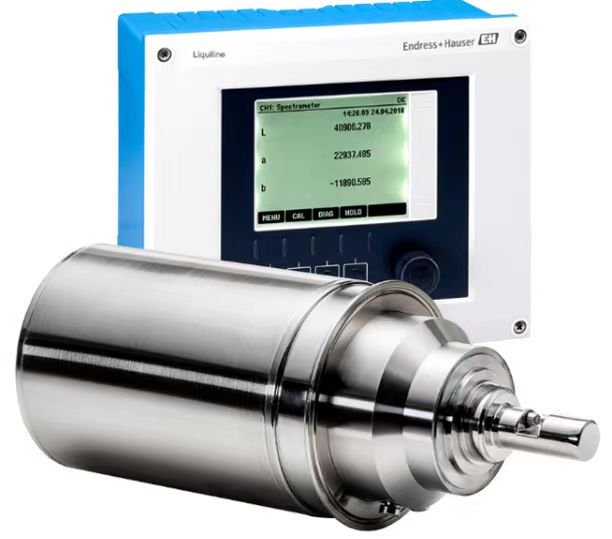

The measurement device, Memosens https://www.facebook.com/profile.php?id=100087291657130Wave CKl50, came into being.

Core functions and advantages:Real-time, full-spectrum color measurement

Memosens Wave CKl50 https://heiautomation.com/about/is capable of measuring integers in real time

The color within the visible light spectrum range (380 to 830nm)

Color. This comprehensive coverage ensures that you can use it with high precision

Laboratory instruments also directly capture the color during the production process

Every subtle difference of color.

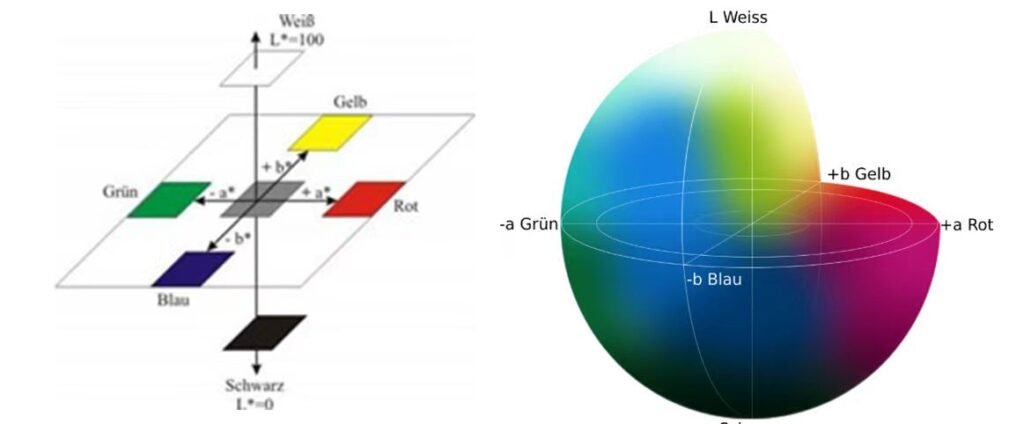

The color data is output in the form of Lab* values, which is one

A general as defined by the DIN EN ISO 11664-4 standard

Color scale. This enables comparisons among different systems and processes

Comparing and communicating color specifications has become a piece of cake.

Real-time process control and intervention

Incorrect color values or color defects will be immediately in your control

It is marked in the system. This real-time feedback enables you to be in

Take corrective measures immediately when the preset limit value is reached to ensure

Deviations can be resolved promptly and efficiently

By integrating Memosenshttps://heiautomation.com/about/ Wave CKl50 into your

During the process, you can maintain the consistency of product quality and avoid

Avoid expensive returns or recalls due to quality issues.

Compact design, easy to integrate

The Memosens Wave CKl50 adopts a compact form factor

It is convenient to install and integrate into the existing production line

Major renovations or additional space occupation are required.

Its innovative design and the uniqueness of Endress & Hauser

The combination of Memosens digital intelligent technology can do without

Integrate the seam into your production process to ensure its perfect fit

Your workflow.

An all-round device suitable for multiple industries

Memosens Wave CKl50 https://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6j/shortsis for food and beverage, chemical industry

It is an ideal choice for many industries such as life sciences. Its sturdiness

Its structure and advanced functions make it suitable for various colors

- Application scenarios with extremely high consistency requirements.

When used in conjunction with the Liquiline CM44P transmitter

Memosens Wave CKl50 is compatible with all common ones

Adopt the communication protocol and fully leverage the advantages of the Liquiline platform

“Trend. This makes it easy to expand and integrate others as needed

Memosens https://heiautomation.com/contact-us/sensors have become possible.

Easy to use and simple to maintain

Memosens Wave CKl50https://heiautomation.com/contact-us/ is designed with simplicity as its principle

Read. No additional technical components are required, nor is in-depth mastery necessary

Professional knowledge in data modeling and process development. Just put it

Connect to your system and you can start measuring.

Its intuitive operation interface and extremely low maintenance requirements ensure that you

You can focus on the production process without worrying about complex calibrations

Or set up the program.

Safety and Compliance

Memosens Wave CKl50 has ATEX

Explosion-proof certificates such as IECEx and UKEx, 3-A, FDA

Hygiene certifications such as EHEDG, even when there may be dangers

It is also possible in harsh environments or those with extremely high hygiene requirements

Ensure safe operation.

Its highest protection level of IP69 ensures the reliability of the equipment and

Its durability enables it to withstand water immersion, vibration and high temperatures, etc

Harsh industrial applications with common challenges.

Examples of application scenarios

The beer industry: Color determines the impression of quality

For beer brewers, the color of beer is a measure of product quality

Key indicators of style. Each style of beer has its corresponding counterpart

The standard chromaticity range. Traditionally, the color of beer was observed manually

Not only is the efficiency low, but it is also highly susceptible to subjective interference.

The emergence of Memosens Wave CKl50https://heiautomation.com/ has completely changed this

A situation. It can accurately measure the color of beer at every stage of brewing

From the preparation of wort to the canning of finished beer, every single one is guaranteed

All batches of beer have a stable color that meets the style requirements

Detergent industry: Stable color highlights quality

The color of detergent is also related to product quality. During the production process, if

Color deviation https://www.facebook.com/profile.php?id=100087291657130not only affects the visual effect but also reduces it

The cleaning effect, in turn, affects the sales of the product.

Memosens Wave CKl50 is provided for detergent manufacturers

A reliable solution. It can monitor the production of detergents in real time online

The color during the process, whether it is the raw material mixing stage or the final product

Before packaging the product, if the color deviates from the preset standard, the system will immediately issue an alarm

Memosens Wave CKl50https://heiautomation.com/product/ Process Spectrometer. Not just

A device, it is a comprehensive solution that can ensure your safety

The consistency of the color of liquid products. By integrating this advanced technology set

When it comes to your production process, whether it is food, beverages or pharmaceuticals,

It’s still industries like chemical engineering and textiles, as long as you have accurate color measurement

It has high requirements for degree and can always be your capable assistant to help you excel

Accurately locate the color coordinates to ensure product qualityhttps://www.instagram.com/sunny.zeng5/.