In the field of automatic control, PLC is an important control device. At present, there are over 200 manufacturers worldwide producing more than 300 varieties of PLC https://heiautomation.com/product/products, which are applied in industries such as automobiles (23%), grain processing (16.4%), chemicals/pharmaceuticals (14.6%), metals/mining (11.5%), and pulp/paper (11.3%). In order to make it more convenient for beginners to understand PLC, this article provides a brief introduction to the development, basic structure, configuration, application and other basic knowledge of PLC, hoping to be helpful to netizens. I. The Development History of PLC In industrial production processes, a large number of switch quantity sequential controls are carried out. It performs sequential actions according to logical conditions and controls interlock protection actions based on logical relationships, as well as collects a large amount of discrete data. Traditionally, these functions have been achieved through pneumatic or electrical control systems. In 1968, the GM (General Motors)https://heiautomation.com/ Company of the United States proposed the requirement to replace the relay electrical control device. The following year, the Digital Company of the United States developed a control device based on integrated circuits and electronic technology, and for the first time applied programmed means to electrical control. This was the first generation of programmable logic controllers. It is called Programmable Controller (PC).

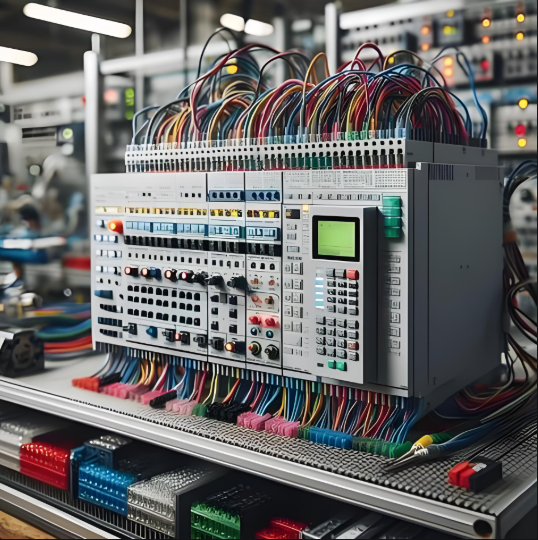

After the development of personal computers (abbreviated as PC), for convenience and to reflect the functional characteristics of Programmable Logic controllers, programmable logic controllers were named Programmable Logic Controller (PLC). Even now, PLC is still often abbreviated as PC. There are many definitions of PLChttps://heiautomation.com/product/. The International Electrotechnical Commission (IEC) defines PLC as: A programmable logic controller (PLC) is an electronic system for digital operation, specifically designed for application in industrial environments. It adopts programmable memory to store instructions for performing logical operations, sequential control, timing, counting and arithmetic operations, etc. within it, and controls various types of machinery or production processes through digital and analog inputs and outputs. Programmable logic controllers and related equipment should all be designed in accordance with the principle of being easy to form an integrated whole with industrial control systems and easy to expand their functions. From the 1980s to the mid-1990s, it was the period when PLC developed the fastest, with an annual growth rate consistently maintained at 30% to 40%. During this period, the capabilities of PLC in processing analog quantities, digital computing, human-machine interface and network have been significantly enhanced. PLC gradually entered the field of process control and replaced the DCS systemhttps://heiautomation.com/, which dominated in the field of process control, in some applications. PLC features strong versatility, ease of use, wide adaptability, high reliability, strong anti-interference ability and simple programming. The position of PLC in industrial automation control, especially in sequential control, is irreplaceable in the foreseeable future. Ii. Composition of PLC \ nIn terms of structure, PLCS can be divided into two types: fixed type and modular type. A fixed PLC consists of a CPU board, an I/O board, a display panel, memory blocks, a power supply, etc. These elements are combined into an undetachable whole. Modular PLCS include CPU modules, I/O modules, memory, power supply modules, base plates or racks. These modules can be combined and configured according to certain rules. Iii. Composition of CPU \ nThe CPU is the core of a PLC and plays the role of a nerve center. Each PLC set has at least one CPU. It receives and stores user programs and data according to the functions assigned by the PLC system program, collects the status or data sent by the on-site input device in a scanning manner, and stores it in the specified registers. Meanwhile, Diagnose the working status of the power supply and the internal circuits of the PLC, as well as syntax errors during the programming process, etc. After entering operation, instructions are read one by one from the user program memory. After analysis, corresponding control signals are generated according to the tasks specified by the instructions to direct the relevant control circuits. The CPU is mainly composed of an arithmetic unit, a controller, registers, and the data, control, and status buses that connect them. The CPU unit also includes peripheral chips, bus interfaces, and related circuits. Memory is mainly used for storing programs and data and is an indispensable component of a PLC.

From the user’s perspective, there is no need to analyze the internal circuits of the CPU in detail, but there should still be a sufficient understanding of the working mechanisms of each part. The controller of the CPU controls the operation of the CPU. It reads instructions, interprets instructions and executes instructions. However, the working rhythm is controlled by oscillation signals. The arithmetic unit is used for performing numerical or logical operations and works under the command of the controller. Registers are involved in operations and store the intermediate results of the operations. They also operate under the command of the controller. CPU speed and memory capacity are important parameters of a PLChttps://heiautomation.com/product/. They determine the working speed of the PLC, the number of IO and software capacity, etc., and thus limit the control scale. Four. I/O Module The interface between the PLC and the electrical circuit is accomplished through the input/output section (I/O). The I/O module integrates the I/O circuit of the PLC. Its input register reflects the status of the input signal, and the output point reflects the status of the output latch. The input module converts electrical signals into digital signals and enters the PLC system, while the output module does the opposite. I/O is divided into modules such as digital input (DI), digital output (DO), analog input (AI), and analog output (AO). A switch quantity refers to a signal with only two states: on and off (or 1 and 0), while an analog quantity refers to a continuously changing quantity. The commonly used I/O classifications are as follows: Switching quantities: Classified by voltage level, there are 220VAC, 110VAC, and 24VDC; classified by isolation method, there are relay isolation and transistor isolation. Analog quantity: Classified by signal type, there are current type (4-20mA,0-20mA), voltage type (0-10V,0-5V,-10-10V), etc. Classified by accuracy, there are 12-bit, 14-bit, 16-bit, etc. In addition to the above-mentioned general IO, there are also special IO modules, such as thermal resistors, thermocouples, pulse modules, etc. The specifications and quantities of the modules are determined by the number of I/O points. The number of I/O modules can be large or small, but their maximum number is limited by the basic configuration that the CPU can manage, that is, by the maximum number of slots on the base plate or rack. V. Power Supply Module \ nThe PLC power supply is used to provide working power for the integrated circuits of each module of the PLC. Meanwhile, some also provide a 24V working power supply for the input circuit. The power input types include: AC power (220VAC or 110VAC), and DC power (the commonly used one is 24VAC). Vi. Base Plate or Rack \ nMost modular PLCS use base plates or racks, whose functions are: electrically, to connect the modules, enabling the CPU to access all the modules on the base plate; mechanically, to connect the modules, making them form an integrated whole. Vii. Other equipment of the PLC https://heiautomation.com/contact-us/system.Programming equipment: The programmer is an indispensable component for the development and application of PLC, monitoring its operation, and inspection and maintenance. It is used for programming, making certain Settings for the system, and monitoring the working conditions of the PLC and the system it controls. However, it does not directly participate in on-site control operations. Small PLCS usually have handheld PLCS. Currently, a computer (running programming software) is generally used as the programmer. 2. Human-machine interface: The simplest human-machine interface consists of indicator lights and buttons. Currently, the application of integrated operator terminals with LCD screens (or touch screens) is becoming increasingly widespread. It is very common for a computer (running configuration software) to serve as the human-machine interface. 3. Input and output devices: Used for permanently storing user data, such as EPROM, EEPROM writers, barcode readers, potentiometers for inputting https://heiautomation.com/about/analog quantities, printers, etc.

Viii. The communication networking of PLCShttps://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6j/shorts, relying on advanced industrial network technology, can quickly and effectively collect and transmit production and management data. Therefore, the importance of the network in the engineering of automated system integration is becoming increasingly prominent. Even some people have put forward the viewpoint that “the network is the controller”. PLC has the function of communication networking, which enables information exchange between PLCShttps://www.facebook.com/profile.php?id=100087291657130, between PLCS and upper-level computers as well as other intelligent devices, forming a unified whole and achieving decentralized centralized control. Most PLCS have RS-232 interfaces, and some have built-in interfaces that support their respective communication protocols. The communication of PLCS has not yet achieved interoperability. IEC has stipulated multiple fieldbus standards, which are adopted by all PLC manufacturers. For an automation project (especially medium and large-scale control systems), the selection of the network is very important. First of all, the network must be open to facilitate the integration of different devices and the expansion of the future system scale. Secondly, in response to the transmission performance requirements of different network layers, the form of the network should be selectedhttps://heiautomation.com/product/. This must be carried out on the premise of having a deeper understanding of the protocols and mechanisms of the network standard. Secondly, by comprehensively considering specific issues such as system cost, equipment compatibility, and suitability for the on-site environment, determine the network standards used at different levels.