Application challenges

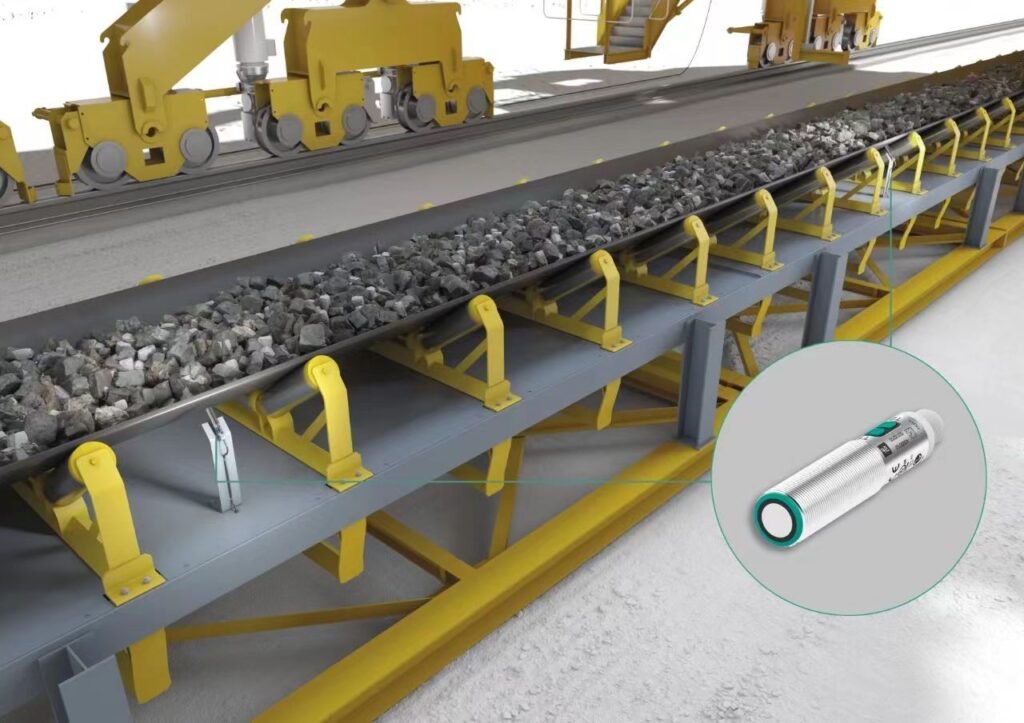

In the mining industry, transporting bulk materials of different volumes over long distances is an important task. Conveyor belts, as an efficient and economical mode of transportationhttps://heiautomation.com/product/, are widely used

To ensure that the conveyor belt maintains better performance and higher efficiency throughout its service life, it is crucial to be equipped with high-quality control and monitoring devices.Pepperl + Fuchs https://heiautomation.com/product/ultrasonic sensors provide effective solutions for the economic, efficient and reliable operation of conveying systems in the mining industry.

Application 1: Measuring the thickness of coal seams in conveyor belts

In mining operations, measuring the thickness of coal seams on the conveyor belt is a key link to achieve continuous monitoring and control of the height of wet ore layers. To this end, we adopt 8 ultrasonic sensors with 10-Link interfaces (such as https://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6j/shortsUC500-18GS-IUEP-I0-V15), which work in coordination with the 10-Link master station module ICE2 and are integrated into the “Coal Seam Thickness Profilator” system to accurately generate ore profiles.

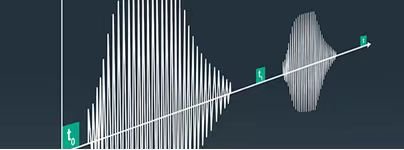

The ultrasonic sensor emits sound waves to the conveyor belt. By calculating the reflection time of the sound waves, the distance between the sensor and the ore is accurately determined, and then the outline of the wet ore layer on the conveyor belt is depicted.

Application 2: Conveyor belt breakage detection

In terms of conveyor belt breakage detection, the UC500-18GSIUEP-I0-V15https://heiautomation.com/contact-us/ ultrasonic sensor is a mature and reliable solution.

The system assesses the integrity of the conveyor belt by monitoring the continuity of data from multiple sensors. Eight sensors are installed beneath the conveyor belt in rows, emitting high-frequency https://heiautomation.com/product-category/danfoss/ultrasonic waves to the belt and measuring the echo data.

When the conveyor belt is in good condition, the sound waves will be uniformly reflected back to the sensor. If cracks or broken bands occur, the continuity of the measurement data will be disrupted. When the conveyor belt moves, the sensor will continuously scan its surface. Once a significant deviation is detected, an alarm will be triggered. Thanks to the synchronization function of ultrasonic sensors, these sensors can be installed adjacent to each other, effectively avoiding mutual interference among the sensors.

Pepperl + Fuchs UC500-18GShttps://heiautomation.com/product/ series ultrasonic sensor;

Product characteristics:The I0-Link interface enables the diversification and convenience of parameter Settings

Support the infrared interface “IrDA” for convenient online monitoring and debugging

It features synchronization function, adjustable https://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6j/shortssound cone and echo suppression characteristics

Outstanding EMC anti-interference performance ensures stable operation.