Will solid-state batteries be the next fulcrum to move the new energy vehicle industry? The wave of solid-state batteries is surging, and its technological breakthroughs centered on solid-state electrolytes are reshaping the industry landscape. In the three key areas of energy density, safety performance, and cycle life, it has already demonstrated leading potential. On the journey of technological innovation, there are no lone heroes. Pepperl+Fuchs https://heiautomation.com/product/has always paid tribute to this magnificent industrial era with continuous innovation in the field of sensors. In the field of lithium battery manufacturing, from coating to liquid injection, every process cannot do without the hard-core protection of safety and explosion-proof. With its deep accumulation of sensor technology, Pepperl+Fuchshttps://www.facebook.com/profile.php?id=100087291657130 has built an integrated explosion-proof solution, using an intelligent sensor matrix to strengthen the safety production line and inject a deterministic force into the upgrade of battery manufacturing!

Typical application scenarios

Coating Positive Electrode Coating Oven https://heiautomation.com/contact-us/1. The positive electrode of the battery contains NMP9 organic solvent, which is prone to volatilize at high temperatures and may cause an explosion.

Filling Process

The volatile and flammable nature of the electrolyte requires the design of explosion protection measures for the production environment.

Packaging Process

The flammable gases emitted by the electrolyte during evaporation and the exhaust gases produced by electrochemical reactions may form an explosive environment.

Solid State Battery Process

Explosion protection for electrolyte grinding dust and anti-toxic and explosion-proof measures for sulfide electrolytes.

Application difficulties and objectiveshttps://www.facebook.com/profile.php?id=100087291657130

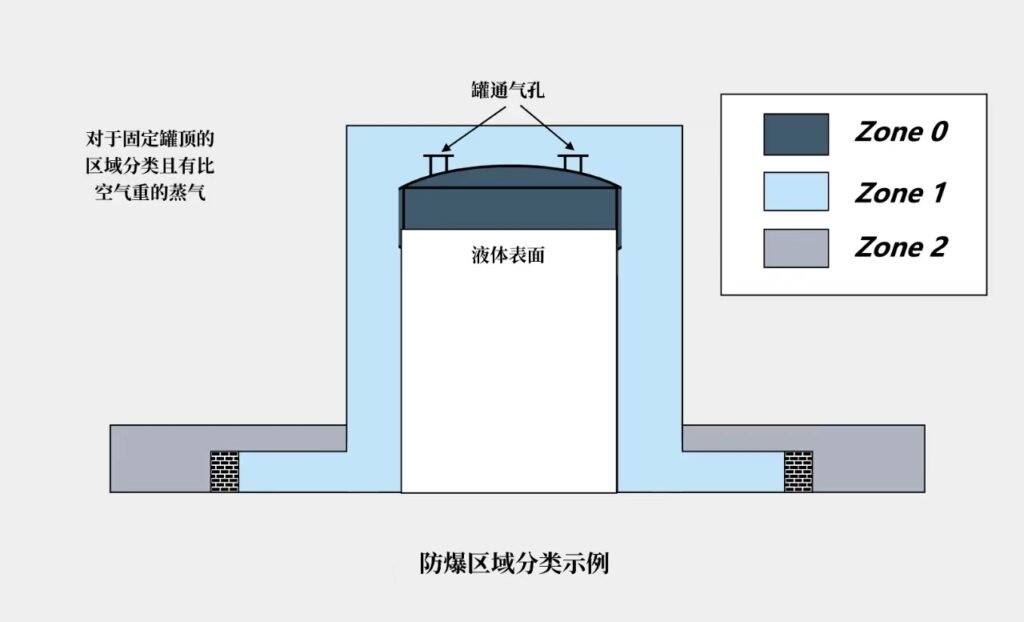

In the coating process, flammable and explosive organic solvents such as https://heiautomation.com/NMP (N-methylpyrrolidone) are often used. When the temperature exceeds 96°C, these solvents will mix with air to form explosive mixtures, posing an explosion risk.

In the plating process, the common liquid electrolyte component lithium hexafluorophosphate exists.

When exposed to high temperatures, it will produce combustible gases, which may lead to an explosion. In the production of solid or semi-solid batteries, solid electrolytes such as sulfides, when exposed to water, will produce toxic gas HS. The production environment must be strictly controlled, and leakage prevention and explosion prevention measures must be taken.

According to the “Design Standards for Lithium-ion Battery Factories” (GB51377-2019),

the explosion-proof requirements for lithium-ion equipment are extremely strict. Ensuring that the equipment complies with these standards is an important step in preventing safety accidents.https://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6j

total solution

p+f, as a leading manufacturer of industrial sensors and sensor systems, offers a reliable range of sensor products for applications in hazardous areas.

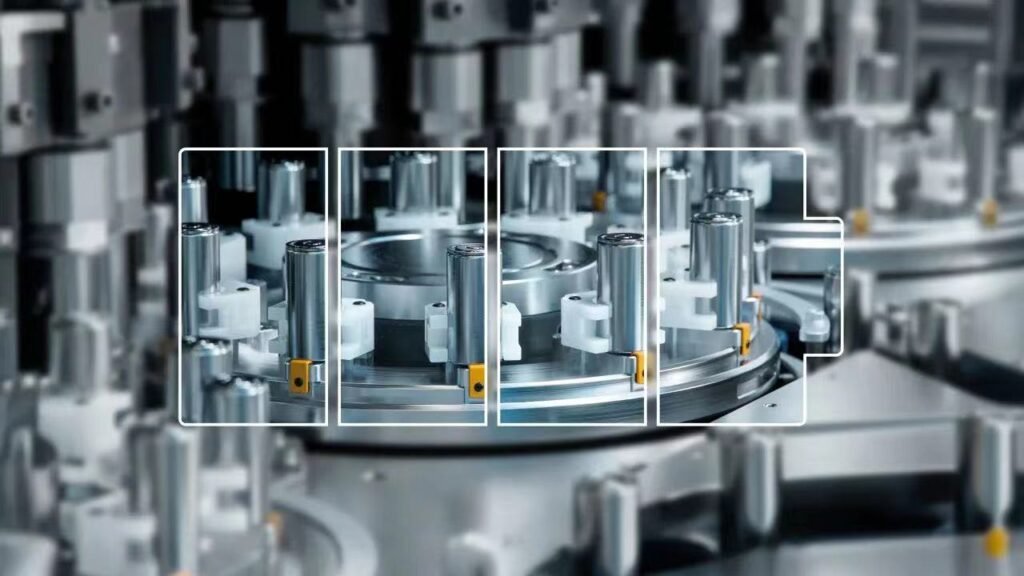

Cylindrical explosion-proof switchhttps://heiautomation.com/about/

In the coating process of the electrode sheet, the explosion-proof proximity switch is used to determine the starting/terminating position of the coating head, ensuring uniform coverage of the slurry; in the drying tunnel, the position of the metal tension wheel on the electrode sheet conveyor belt is monitored to prevent the conveyor belt from causing the electrode sheet to fold, and at the same time to avoid sparks generated by metal friction.

Slot-type explosion-proof switch

The explosion-proof area can use slot-type switches to detect the position signals of cylinder fixtures, slide table modules, injection needle heads, etc. The slot-type switch has thicker cables, which are more convenient for terminal selection and wiring.https://heiautomation.com/

product features

Rich in sizes, round type

(minimum diameter

5mm), square type, slot type are available for selection, meeting the requirements of different application scenarios.

Intrinsically safe explosion-proof method, voltage and current are controlled at a sufficiently low level (8.2V power supply, when the target object is detected, ≤1mA), allowing for maintenance, calibration and replacement of parts while powered on.

Excellent shell processing technologyhttps://www.facebook.com/profile.php?id=100087291657130 and material selection ensure extremely low resistance values and good anti-static ability.

Comprehensive certifications are available, including CE, UL, UKCA, ATEX, IECEx, CCCex, etc.

The internal part uses high ductility resin for injection molding, providing high-level protection capabilities.

p+f – A Leader and Innovator in Future Automation