Amid the sweeping transformation of the global energy landscape, China’s battery industry is like a powerful giant ship, forging ahead with full steam. In recent years, it has made continuous breakthroughs in technological https://heiautomation.com/product/innovation, witnessed a sustained expansion of market scale, and seen an increasingly optimized industrial layout, achieving remarkable accomplishments and emerging as the core engine driving the global battery industry’s transformation. The rapid development of the new energy vehicle industry and the power storage market has acted as a powerful engine, fueling a surge in demand across various segments of the battery industry and propelling the industry’s scale to new heights. The integration of photovoltaic, storage, and charging is opening up a new track in the new energy sector, and Pepperl+Fuchs’ photoelectric sensors are shining brightly on this track, demonstratinghttps://www.facebook.com/profile.php?id=100087291657130 their prowess.

As a driver and innovator in the global sensor field, Pepperl+Fuchs has always regarded the application in the battery production process as an important research direction of the company. Nowadays, many links in the lithium battery industry cannot do without the assistance of Pepperl+Fuchs products. With intelligent sensors and cutting-edge technology, we enhance the reliability and effectiveness of the productionhttps://heiautomation.com/contact-us/ line for our customers.

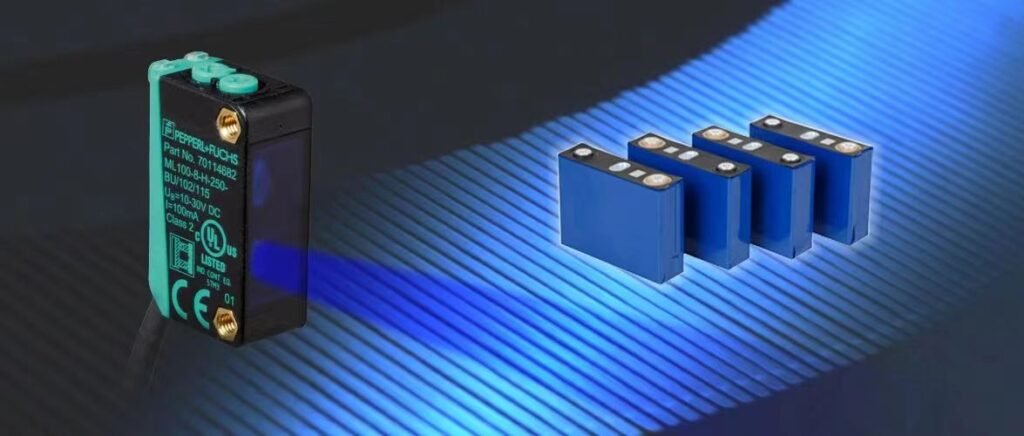

ML100 Series – Universal Problem Solving Expert

Blue film detection

During the battery production process, the ML100 serieshttps://heiautomation.com/contact-us/ photoelectric sensors, with their unique advantages, are widely applied in various scenarios. During the cell encapsulation process, the cells need to be assembled inside a metal casing and fully sealed, involving processes such as tab welding, adhesive application, shell punching, and sealing.

Among these processes, the handling and positioning of the battery casing and internal components are of crucial importance. The diffuse reflection type sensor of ML100 can play a significant role. It can detect the position of the battery components on the conveyor line and guide https://heiautomation.com/the mechanical arm to accurately grasp and place them.In addition, the blue-light type sensor of the ML100 series performs exceptionally well in detecting materials with low reflectivity (such as specific silicon wafers) during battery production. It uses a modulated blue light with a wavelength of 470nm. Compared to the traditional red light LED sensor with a wavelength of 650nm, the detection accuracy has been significantly improved. Li

Using the ML100 blue-light type sensor to inspect the new silicon wafers, even when the edge of the silicon wafers has significant fluctuations, it can still perform reliable detection, providing accurate data support for battery research https://heiautomation.com/contact-us/and development.

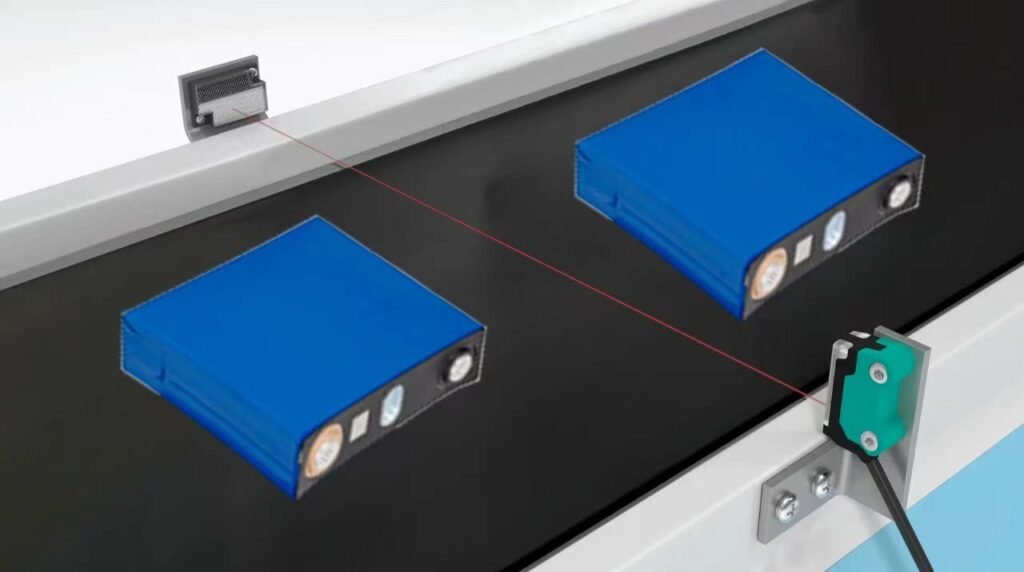

R2/R3 series -Expert in detecting small targets with high precision

In battery production, the R2/R3 series laser photoelectric sensors are suitable for various critical detection tasks due to their compact size, small light spot and high precision. In the cell detection stage on the conveyor line, if there are thin cells, the conventional LED light source photoelectric sensors are difficult to achieve stable detection.

By using the R2R3 laser type products, stable detection of ultra-thin cells or judgment of cell protrusions https://heiautomation.com/about/can be achieved, and they also have high cost performance.

In the quality inspection process after the cutting of battery electrode sheets, minor defects (such as burrs and notches) at the edges of the electrode sheets can affect the performance of the battery. The R2/R3 series, with its small light spots, can clearly detect the edge defects of the electrode sheets. For the collimated laser sensor, the light spot is small and, in combination with the Teach function, it can reliably detect the subtle defects at the edge of thehttps://heiautomation.com/ electrode sheets, effectively improving the quality control level of the electrode sheets.

R100 Series – Fighter Aircraft in the Laser World

The R100 series photoelectric sensors play a crucial role in the long-distance detection and high-precision requirements scenarios in battery production. In large battery production workshops, when battery modules are transported over long distances between different processes, their positions and states need to be monitored in real time.

The R100 series laser sensors, based on the DuraBeamhttps://www.facebook.com/profile.php?id=100087291657130 Laser technology that is safe for human eyes, have a longer service life compared to traditional lasers, and can form small and circular bright spots. Installation does not require consideration of the running direction of the target object. The 300mm background suppression type is suitable for close-range detection, with the light spot being only 1mm at 200mm. The detection distance for the reflective or reflective plate type can reach 20m, enabling accurate detection of whether each cell in the battery module group is placed in the correct position at a long distance.

Automated solutions for the battery industry

Pepperl+Fuchshttps://www.facebook.com/profile.php?id=100087291657130 offers a wide range of product solutions for battery automation equipment:

Anti-corrosion ultrasonic sensors for measuring the level of corrosive slurry:

It can accurately measure the slurry level in harsh chemical environments, ensuring the stability of the production process.

Color mark sensors for automatic rewinding identification in coating/roller pressing and cutting operations:

They can quickly and accurately identify rewinding marks, enabling automatic rewinding operations and improving production efficiency.

Vibration sensors for monitoring vibration abnormalities in the laminating and folding machine:

They can monitor the vibration status of the equipmenthttps://studio.youtube.com/video/d-1jAFjjPHU/edit in real time, promptly detect potential faults, and ensure the normal operation of the equipment, etc.

In addition, Pepperl+Fuchs is also an important partner for battery end-users, providing complete traceability system solutions for battery production!