In the automated production process, the automatic assembly stage plays a crucial role in the final quality and production efficiency of the products.

To ensure the accuracy of the automatic assembly process and avoid a series of quality issues and production delays caused by incorrect assembly, it is necessary to conduct a pre-confirmationhttps://heiautomation.com/product/ of the products before the assembly. Among them, the pre-feeding position in the assembly line for checking whether the product has been printed with the necessary information is a key pre-step to ensure the assembly quality.

application requirement:There is no inspection for the printing of characters https://heiautomation.com/on the products at the station of the feeding inlet before assembly.

Application Challenges:There may be cases where the printed characters https://www.facebook.com/profile.php?id=100087291657130are missing or the IC is reversed at the workstation.

Banner Solution:

Use the Banner iVu2PTGR12https://heiautomation.com/contact-us/ visual sensor

Application of the plan:Use the iVu to measure the distance from the sensorhttps://heiautomation.com/ to the object at a height of 100mm above the workpiece.

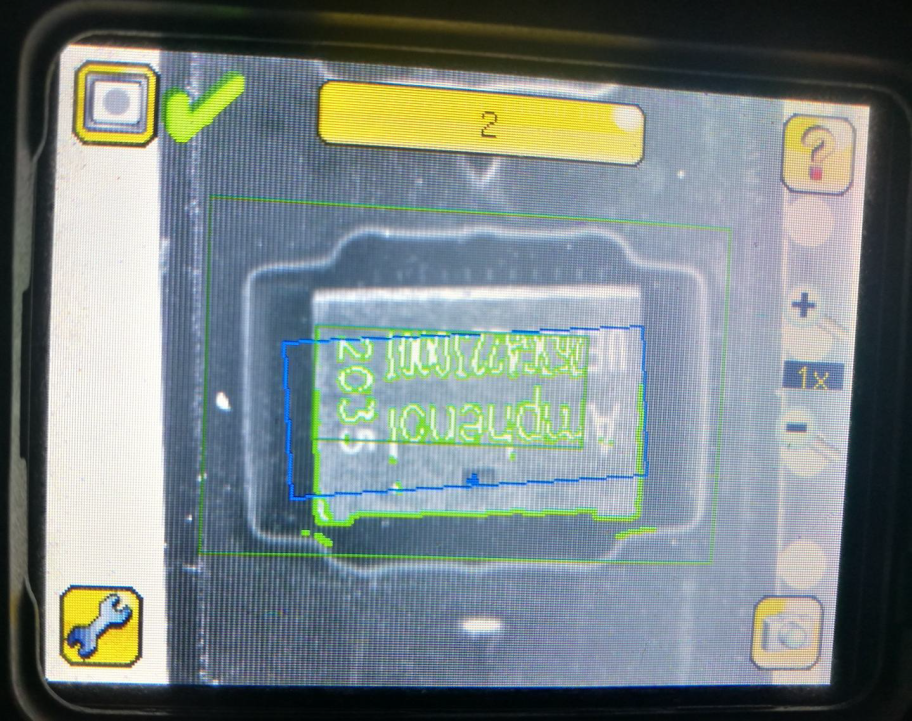

Use the graphic tool for positioning on-site, and then use the spot tool for detection.

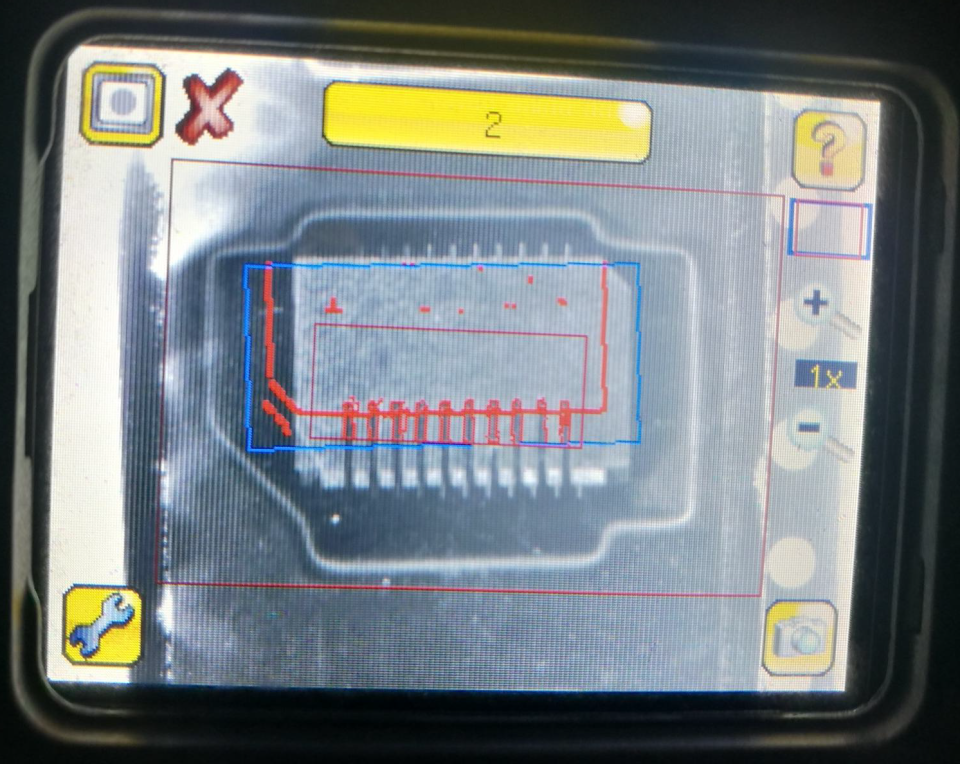

The iVu is installed directly above the workpiece and detects on the workstation. Under normal https://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6jconditions, it outputs an OK signal (output 1), while for cases with missing or reversed characters, it outputs an NG signal (output 2).

Use the graphic tool for positioning, and then use the spot tool to detect the IC; when the IC is on the front withhttps://www.facebook.com/profile.php?id=100087291657130 characters, it outputs an OK signal. Number.

Use the spot tool to detect the IC; when the IC is reversed or has no printed characters, output the NG signal.

Why Banner?Quick response and excellent technical services

The installation of iVu is simple and the operation teaching is easy

iVu has a fast response and high protection level

The Ethernet method enables convenient “command communication” with the upper computer

Customer benefits.Improved work efficiency and stabilizedhttps://heiautomation.com/ product quality.