Whether it is cell culture,https://heiautomation.com/product/

microbial culture, or

genetic recombination technology, the raw materials obtained through biotechnological means all have extremely strict requirements in terms of “sterility”.

In the context of aseptic assurance, in which stages of the biotechnology process is PUPSIT applied?https://heiautomation.com/

Which control devices are more suitable for the PUPSIT application?https://www.facebook.com/profile.php?id=100087291657130

Not only must reliable control of the liquid path’s on-off be achieved, but also contact with the medium inside the pipeline must be avoided – is there any solution that can perfectly meet the high standards required by PUPSIT?https://heiautomation.com/

Festo’s pneumatic pipe clamping valve is developed based on the actual application requirements of customers. It offers customized services and can conduct targeted tests according to the specific usage scenarios of customers, ensuring a perfect match with the on-site working conditions.https://www.facebook.com/profile.php?id=100087291657130

Adaptable silicone tubes with an outer diameter of 1/4″ – 1″. Compatible with woven tubes.

Optional proximityhttps://heiautomation.com/contact-us/ switch;

Media isolation: The valve body has no contact with the medium, eliminating the risk of contamination;

Bidirectional flow, no flow resistance, no dead zones, easy to clean;

Flexible adaptation: The same clamp valve can be compatible with different soft tube sizes within a certain range;

Safe and reliable: Unique clamp head design ensures that the soft tube will not slip out during use;

Two valve functions: 2/2 open and 2/2 closed. 2/2 closed valve installation method: Flange on the front or rear side of the panel.

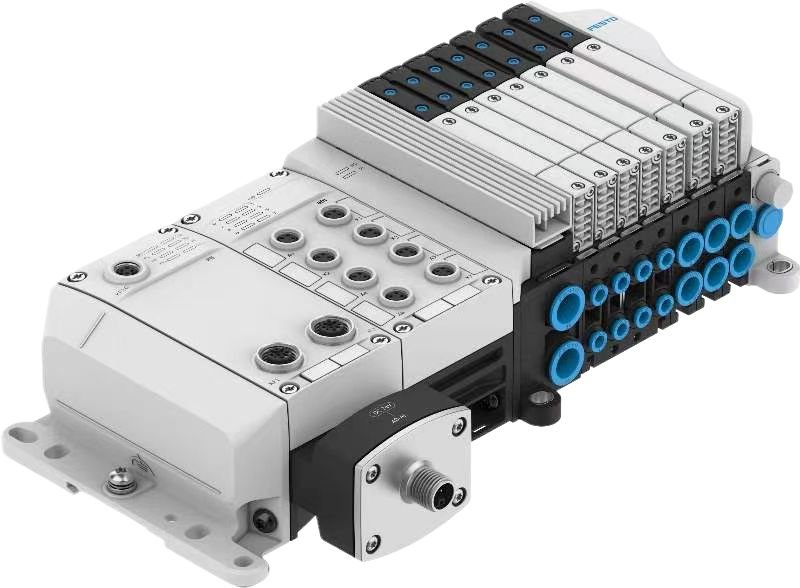

Festo’s latest generation VTUX valve manifold, which seamlessly https://studio.youtube.com/channel/UC5jh-_J8N51BACPDqMnnT6Q/videos/short?filter=%5B%5D&sort=%7B%22columnType%22%3A%22date%22%2C%22sortOrder%22%3A%22DESCENDING%22%7Dintegrates with the clamp-on valve, offers even greater advantages.

The hardware design is more lightweight https://heiautomation.com/about/and compact;

It can integrate remote I/O modules and combine with CPX-AP communication module to build a flexible topological architecture, adapting to various on-site layouts;

Optional Smart Switching Lite energy-saving valve plates can be selected to improve energy efficiency and reduce costs;

The base is equipped with an intelligent chip, supporting the integration of multiple functional sensors to collect underlying data; Combined with Festo software products, it can easily achieve digital upgrades such as predictive maintenance and digital twin factorieshttps://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6j.

Festo pneumatic pipe clamping valvehttps://heiautomation.com/

+VTUX valve manifold, providing a high-precision, highly reliable one-stop control solution for the PUPSIT process, helping to maintain the “sterile” standard.