Overview

In a previous article, we introduced https://heiautomation.com/the imaging principle of Scatter scatter plots, how to collect Scatter scatter plots using the Ranger3/Ruler 3D camera, how to set parameters, and related application cases. Based on Scatter scatter plots, we introduce SICK’s new surface imaging patent technology, Surface+, which can perform high-sensitivity detection of object surfaces, especially suitable for identifying https://www.facebook.com/profile.php?id=100087291657130micro-scratches, indentations, and gloss differences.

In most industries, surface inspection applicationshttps://www.facebook.com/profile.php?id=100087291657130 typically require obtaining both 3D and 2D images. The 3D image is used for measuring dimensions and detecting surface irregularities such as depressions, while the 2D image is used to identify fine scratches or gloss defects visible under specific lighting conditions. Now, with SICK’s new technology, Surface+, both of these inspection tasks can be accomplished with just one camera!

The Surface+ technology can simultaneously obtain 2D and 3D imageshttps://heiautomation.com/about/ in a single image acquisition process, and the 2D and 3D images are precisely aligned in the same coordinate system. This feature makes Surface+ suitable for a wide range of applications, such as the consumer goods industry, the automotive sector, the electronics industry, and various processes involving wood, metal, or steel processing.

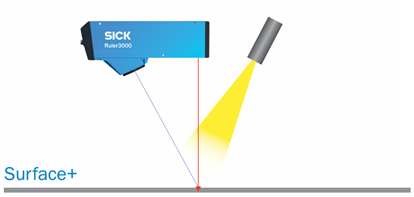

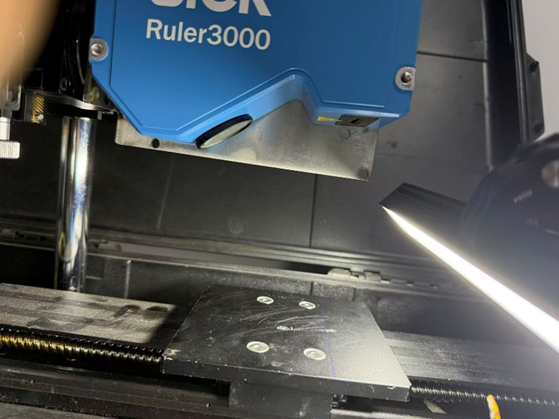

way to install.By adding external lighting, Athttps://heiautomation.com/product/

During the image acquisition process of Ruler3000/Ranger3, it works like a 2D line scan camera to obtain 2D images, which can present additional image dimensions without the need for a separate 2D vision sensor.

The Surface+ must be used in conjunction with external lighting to functionhttps://heiautomation.com/contact-us/ properly. Different light sources are suitable for different detection requirements:

Dark-field light: Suitable for scratch detection 。

Specular Light: Suitable for detecting surface gloss/coating defects

Universal Diffuse Light: Suitable for detecting various types of defects

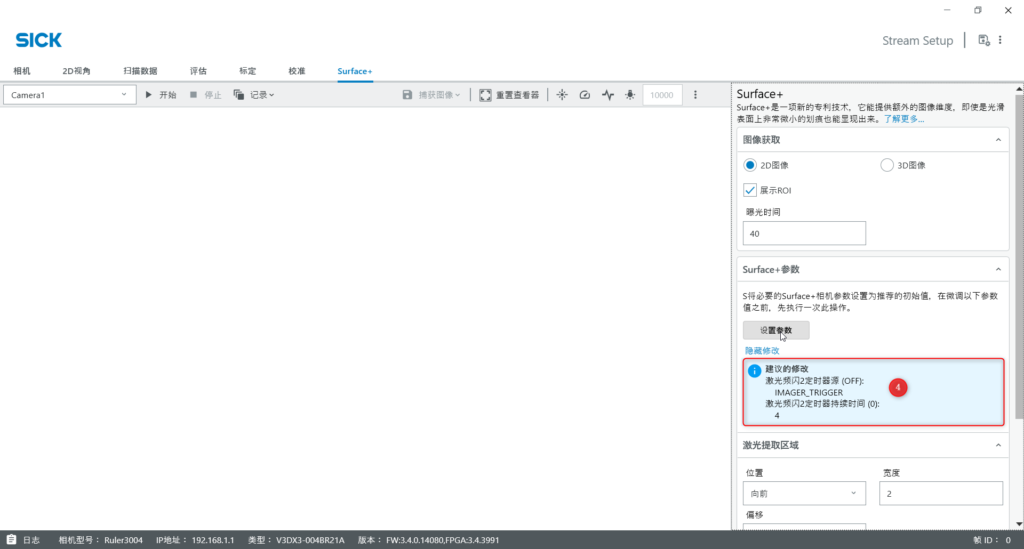

operating steps.The Surface+ function has been integratedhttps://heiautomation.com/about/ into the latest version of SICK’s software. The operation is convenient and simple.

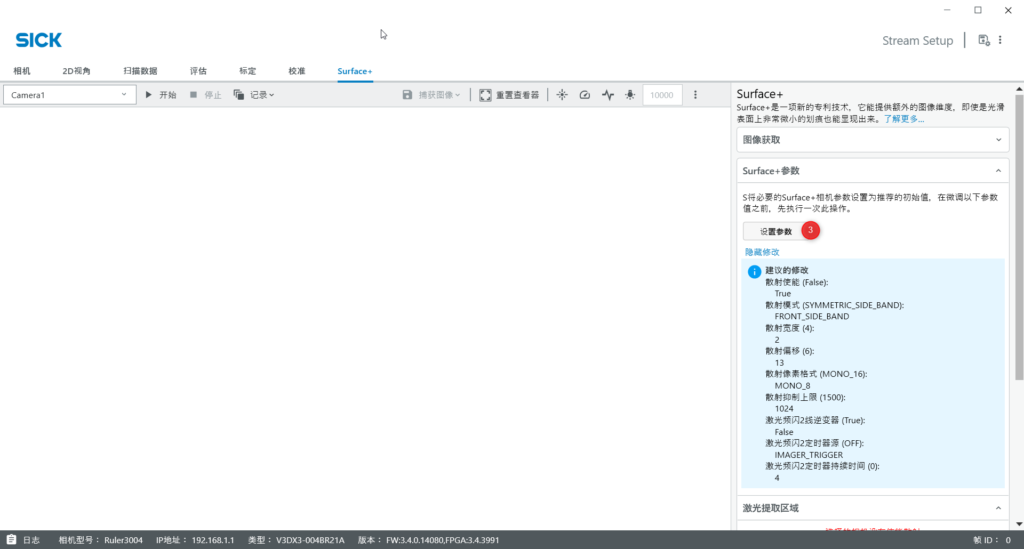

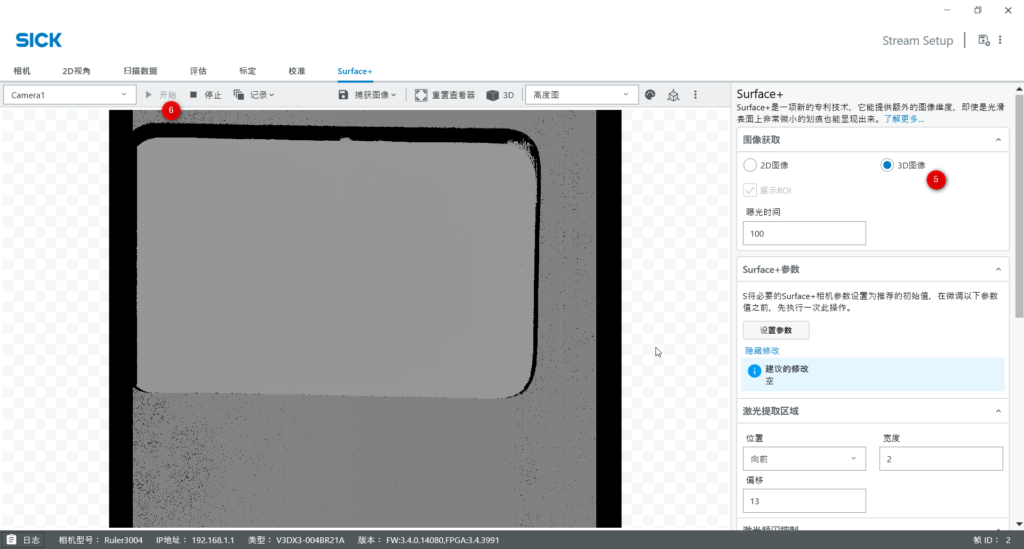

After setting the parameters, select “3D Image” and click “Start” to collect the images.

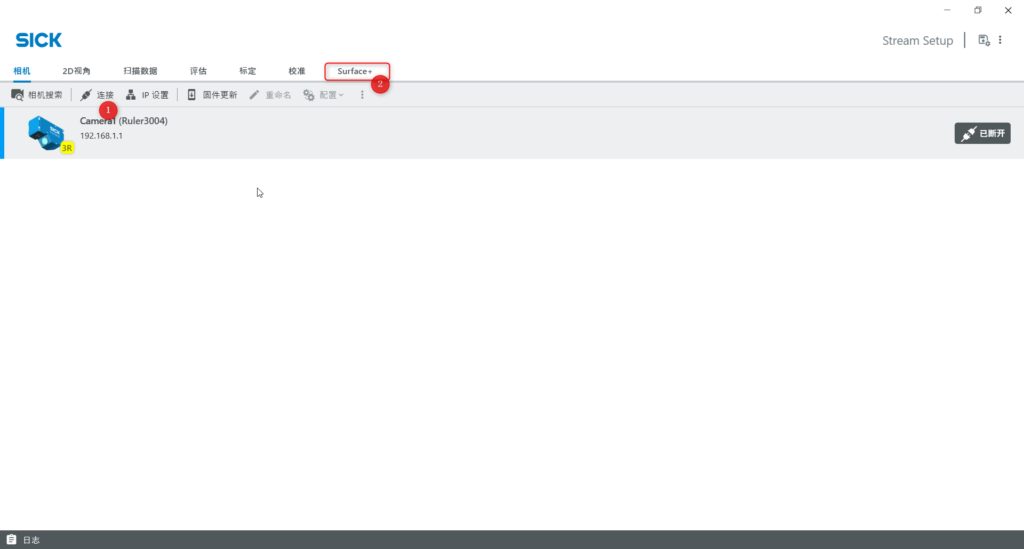

On the SICK China website, search for “Stream Setup” and download the latest version. Right-click and install as an administrator.

Select the appropriate LED source and installation layout based on the project’s detection content.

Start the “Stream Setup software” and ensure that thehttps://heiautomation.com/about/ camera is connected. Click on “Surface+”, and enter the corresponding settings interface.

Click on “Set Parameters”, and the system will automatically set the basic settings for collecting Surface+ images.

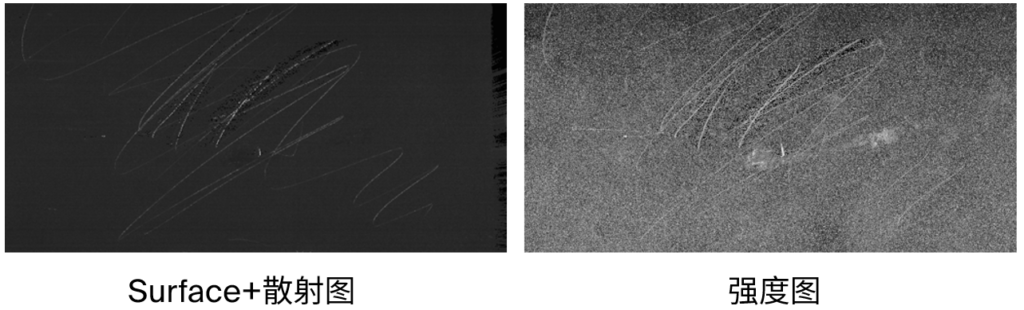

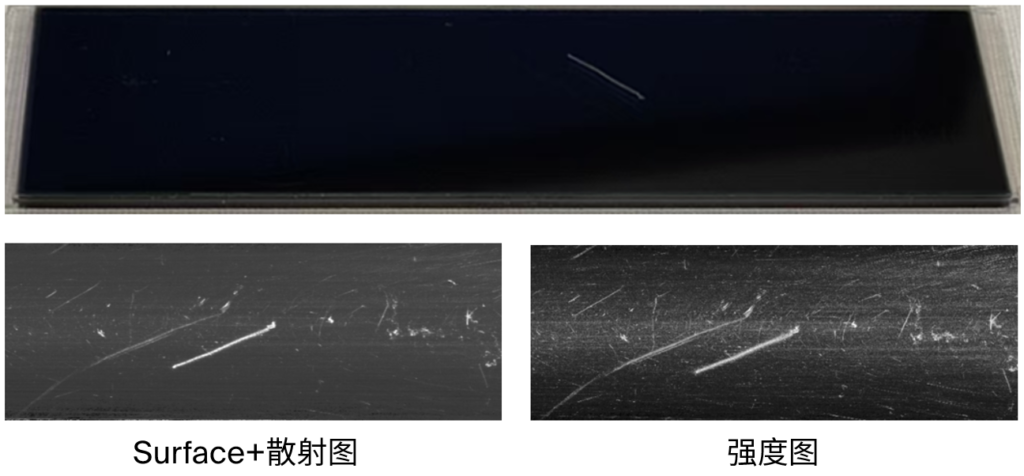

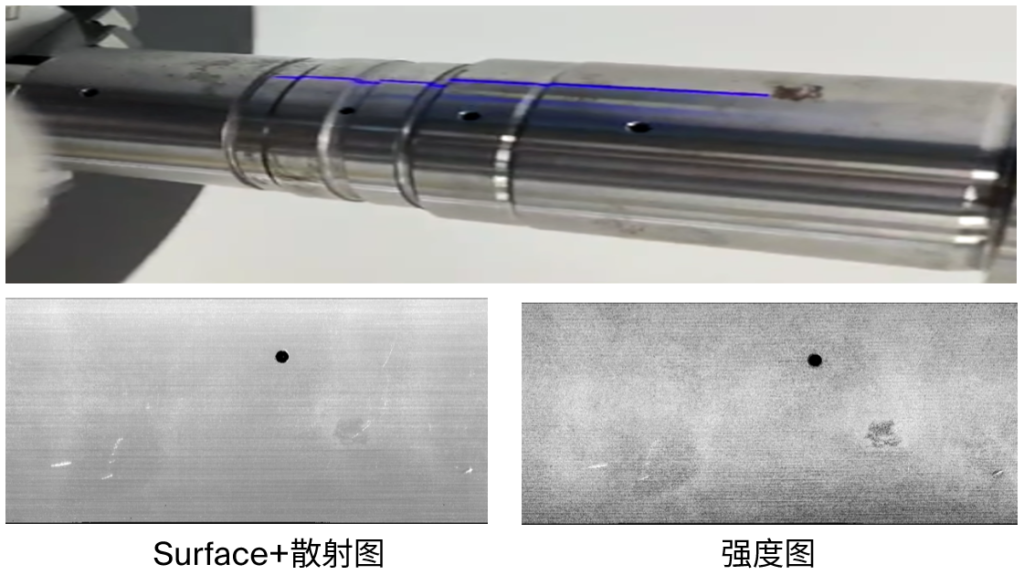

application case.By comparing the effects of the Surface+ scatteringhttps://heiautomation.com/contact-us/ map and the laser intensity map of the images, we found that the scattered map collected under Surface+ has less background noise in the image and a more distinct contrast, which is more convenient for subsequent image processing. Reasoning

The surface of the testing machine

Glass sample

Metal sample

Advantages of Surface+ Easy to use

- A single camera can capture multiple image componentshttps://heiautomation.com/ and achieve precise alignment of 2D and 3D images.

The performance is stable and reliable. - The required installation space is smaller, making it suitable for limited spaces. Application scenario