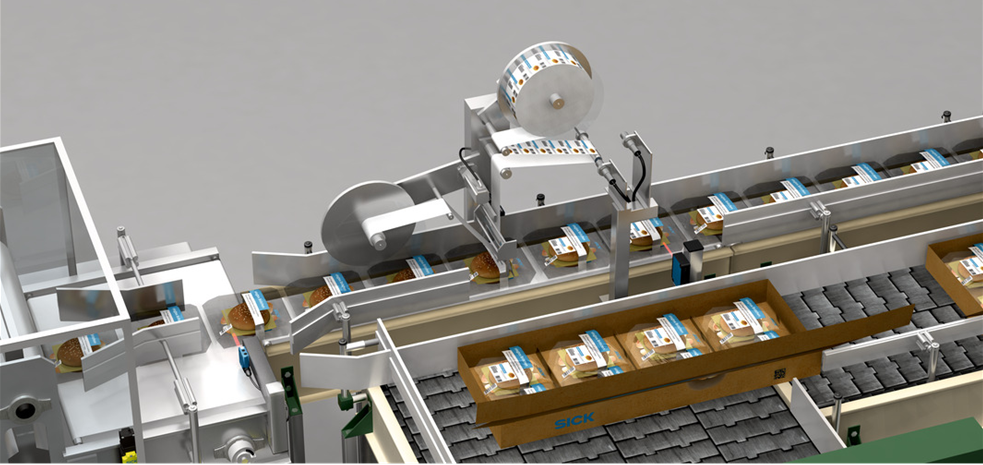

Slot-type sensor:On the high-speed labeling production line, even a minor mistakehttps://heiautomation.com/ such as a missed label application or an off-center position can lead to the scrapping of the product and affect the overall efficiency. The key component that determines whether the labeling machine can accurately capture each label is often that seemingly insignificant “slot sensor”. It is like the eyes of the labeling machine. How to select the right “sharp eyes” is a matter that every labeling machine manufacturer needs to pay attentionhttps://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6j/shorts to.

Generally, like other types of sensors, the slot-shaped sensor needs to “keep up” with the production speed of the machine, meet the precision requirements of the machine, fit the installation space of the https://heiautomation.com/contact-us/machine, comply with the electrical parameters of the machine, and adapt to the width, thickness and material of the object to be inspected. The important parameters are as follows:

Response time/Switch frequency: This determines whether the sensor can keep up with the maximum speed of the labeling machine; Detection accuracy (beam width): The finer the beam inside the slot, the more accurate the detection position; Physical size: Suitable for the installation space of the labeling machine; Slot depth: Leave an appropriate margin to prevent material deviation; Slot width: Ensure that the label can pass smoothly; Outputhttps://heiautomation.com/about/ signal: Make sure that the PLC or controller supports NPN or PNP input; Power voltage: The most common is DC 12-24V, just check and confirm; Environmental protection: If the production line is dusty and humid, it is necessary to choose a model with a high protection level (such as IP67) to ensure that the sensor is not contaminated inside and works stably. Additionally, it is more important to confirm the material of the label. Currently, for different label materials, the two main types of slot-shaped sensors that are popular on the market are:

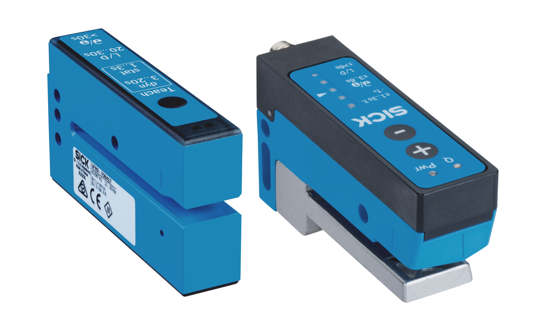

1、Common models – Photoelectric slot sensors, such as SICKhttps://heiautomation.com/product-category/danfoss/‘s WF and WFS。Working principle: Light is emitted from one side of the slot and received from the other side. When the tag passes through the slot, it blocks the light, and the sensor then generates a “detected” signal. Advantages: Fast response speed, relatively low cost. Disadvantages: Easily “tricked” by the color and transparency of the detectable object. For transparent tags, the light passes through directly and it may not respond at all.

(Left image: WFS; Right image: WF)

(Image: Non-transparent label)

Picture: Photoelectric Slot Sensor

2、All-in-one type – Ultrasonic slot-shaped sensors, such as https://heiautomation.com/contact-us/SICK’s UF and UFS。Working principle: It operates by emitting and receiving ultrasonic waves. When the tag passes by, it interferes with the propagation of the sound waves, and thus can be detected. Advantages: It can stably detect tags of any transparency, whether transparent, semi-transparent or opaque. It is particularly good at dealing with tags and base papers with similar colors. Weaknesses: Slow response speed, high price, and insensitive to sound-absorbing materials.

Left image: UF; Right image: UFS。

Picture: Transparent Label

Picture: Ultrasonic Slot Sensor

Soon, SICKhttps://www.facebook.com/profile.php?id=100087291657130 will launch a more “all-round” and more “economical” capacitive slot sensor named CFM/X. This is a capacitive slot sensor that determines the presence of the measured object by detecting the change in capacitance caused when the object enters its electric field. It combines the advantages of photoelectric and ultrasonic sensors while avoiding their respective drawbacks:

More all-round than photoelectric slot sensors: compatible with both transparent and non-transparent labels; More all-round than ultrasonic slot sensors: faster response frequency, up to 500m/min; More economical than ultrasonic slot sensors: two slot depths: suitable for different label sizes, labeling machine space; Two slot widths: suitable for different label thicknesses, 0.4mm/1mm; Multiple connection methods: adaptablehttps://heiautomation.com/about/ to different installation methods; Three working modes that can be freely switched: high-speed mode, high-precision mode, standard mode

Picture: CFM/X can accommodate both transparent and non-transparent label materials simultaneously.

Capacitive slot-type sensor