What are AI/AO/DI/DO? Taking the 5WBB flowmeter https://heiautomation.com/product/as an example. In the production site of industrial automation, the reason why sensors, actuators and control systems can “cooperate seamlessly” is all due to a set of universal “signal language” – AI, AO, DI, DO. These four seemingly simple abbreviations are the core veins that connect equipment interaction and achieve precise controlhttps://heiautomation.com/.

- Analog and Digital Quantitieshttps://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6j/shorts

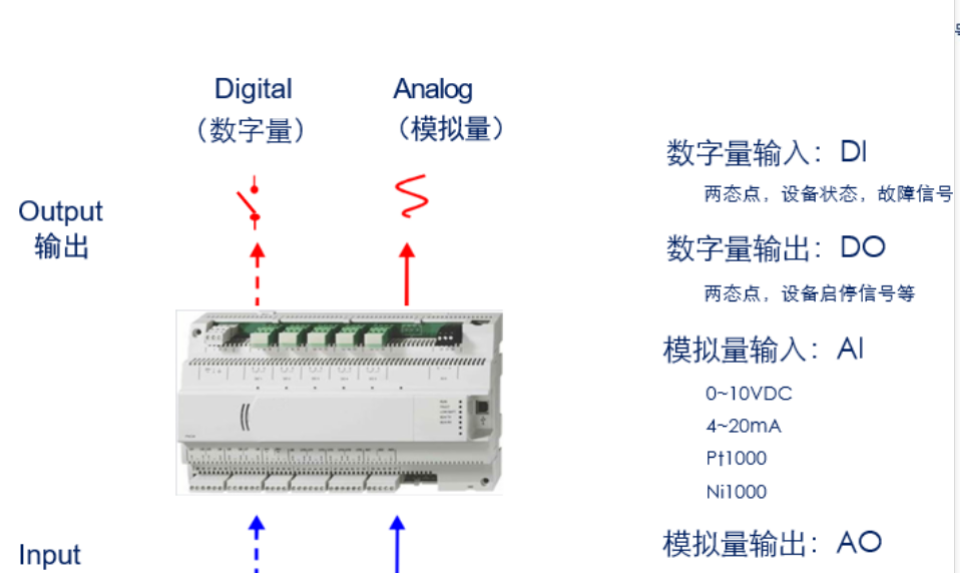

AI, AO, DI, and DO can essentially be divided into two camps, corresponding to different transmission requirements. To understand this easily, let’s use a real-life scenario as an analogy:

Analog quantity: A continuously changing “degree signal”, like adjusting the volume, from mute to the loudest, there are countless levels.

Digital quantity: a “status signal” that is either black or whitehttps://heiautomation.com/about/, like flipping a light switch, with only two fixed states: on and off.

II. Four Signals

Analog Input (AI)

Core Function: Sensor → Control System, transmitting continuous changing measurementhttps://heiautomation.com/ data.

Simple analogy: A thermometer measures body temperature. The continuous values such as 36.5℃ and 37.2℃ are “analog quantities”, which are transmitted to the brain for the purpose of judging whether the body temperature is normal.

Industrial scenario: The -10V to +10V signal from the temperature sensor, and the 0-5V signal from the pressure sensor, are both AI signals that precisely reflect the “real-time status” of the equipment’s operation.

Analog Output (AO)

Core function: Control system → Actuatorhttps://www.facebook.com/profile.php?id=100087291657130, issuing continuous control instructions for adjustment.

Common analogy: The brain instructs the air conditioner to adjust the temperature from 26℃ to 24℃. This “gradual adjustment instruction” is the analog output.

Industrial scenario: The control system outputs a 4-20mA signal to adjust the opening degree of the regulating valve, thereby achieving precise control of flow and pressure.

Digital Input (DI)

Core function: Field devices → Control system, transmitting “present/absent” and “yes/no” status signals.

Simple analogy: The door access sensor at the entrance detects whether the door is “fully closed” (state 1) or “not closed” (state 0), and then sends the information to the central control system.

Industrial scenario: Signals indicating valve opening/closing completion, feedback on equipment operation/fault status, and signals triggered by on-site buttons, all are DI signals.

Digital output (DO)

Core function: Control system → Field equipmenthttps://heiautomation.com/about/, issues “trigger/not trigger” switch instructions.

Simple analogy: The brain issues the “turn on the light” command. The switch closes and the light bulb lights up. This command is the digital output.

Industrial scenario: The start/stop of the motor, the opening/closing of the solenoid valve, and the on/off of the fault indicator light are all driven by DO signals.

III. Case Study

The 5WBB model is capable of adapting to complex workinghttps://heiautomation.com/about/ conditions such as water, sand, and acid solutions. Its abundant signal interfaces perfectly illustrate the collaborative working logic of the four types of signals, and it is also a typical application scenario in industrial settings.

AI signal linkage: The flow value measured by 5WBB is output through a 4-20mA analog signal and is used as an AI input to be transmitted to the PLC/DCS system. If an auxiliary module is configured, it can also receive AI signals from temperature and density sensors to perform flow compensation calculations, thereby improving measurement accuracy.

AO signal application: The 5WBB model is equipped with 1-2 channels of 4-20mA analog output, which is the core flow signal. For instance, when the flow reaches the full scale, it outputs 20mA; when there is no flow, it outputs 4mA. This enables the control system to accurately capture the continuous changes in flow and precisely control the production rhythm.

DI signal interaction: Supports 2-4 DI inputs, capable of receiving external https://www.facebook.com/profile.php?id=100087291657130switch signals – such as feedback on valve opening/closing status, or “reset/calibration” trigger instructions issued by the control system, enabling functional interconnection between devices.

DO signal warning: Standard configuration includes 2-4 DO outputs. When the flow exceeds the limit, electrode failure occurs, or the lining wears out, an immediate dry contact alarm signal will be output, causing the on-site indicator light to flash or triggering the system alarm; at the same time, a pulse signal can also be output for precise measurement of cumulative flow.

IV. Summary

AI, AO, DI, and DO do not exist independently; instead, they form the “neural network” of an industrial system: data is collected from sensors (AI), then analyzed by the control system and followed by the issuance of adjustment instructions (AO) and switch instructions (DO), and finally the feedback of equipment status (DI), creating a complete control loop.

High-end electromagnetic flowmeters like 5WBBhttps://www.facebook.com/profile.php?id=100087291657130, with their flexible signal configuration, can not only meet the measurement requirements of complex working conditions, but also seamlessly connect with various control systems, thus becoming a reliable “data link” in industrial production.