Characteristics of Tsubaki Chains

- High Strength and Durabilityhttps://heiautomation.com/product/

Tsubaki chains are renowned for their high strength and durability, which are fundamental criteria forevaluating chain quality. Strength is not only reflected in tensile strength but also includes aspects such aswear resistance. For example, construction machinery and agricultural machinery require chains with hightensile strength, while chemical production environments necessitate chains with strong corrosion resistance.

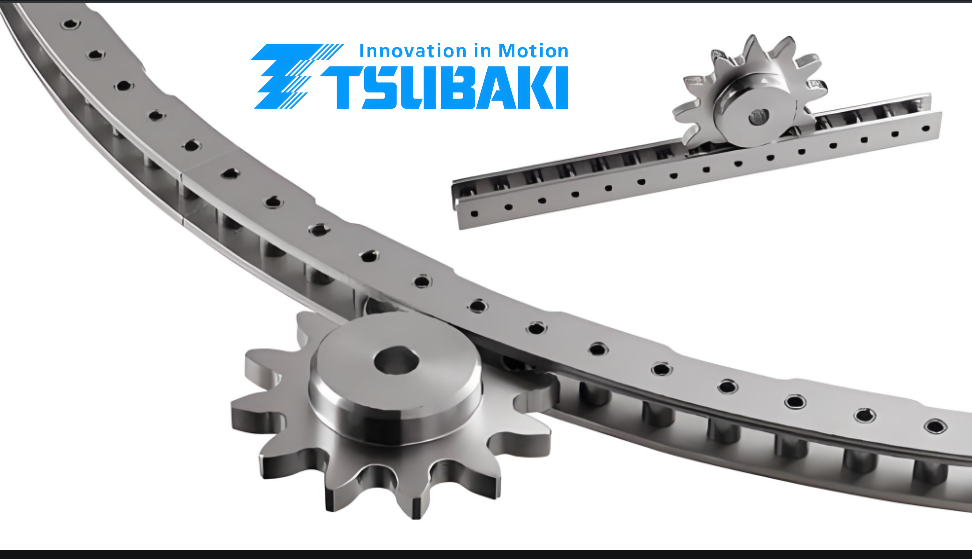

Isubaki’s high-strength chains achieve this by altering the shape of the chain plates and increasing theirthickness, preserving a compact design while ensuring excellent transmission capabilities, load capacity, andtensile strength. This makes them ideal for use in harsh conditions with large impacts and in machinery orequipment that reguires space-saving designs, such as construction machinery, agricultural machinery, liftingmachinery, port machinery, and multi-story parking lots.

2.Corrosion Resistance and Wear Resistancehttps://heiautomation.com/

Isubaki chains exhibit excellent corrosion resistance and wear resistance, enabling them to operate in adverseenvironmental conditions with a long service life. Their heat resistance and oxidation resistance areoutstanding, effectively preventing iron oxidation, thus allowing long-term use in high-temperature, corrosivemedia, and dusty environments.

Stainless steel chains, in particular, offer corrosion resistance, chemical resistance, and heat resistance, makingthem suitable for use in specific environments, especially in the food machinery industry.

- Diverse Material Optionshttps://heiautomation.com/about/

Tsubaki offers a variety of material options to meet the needs of different industries and environments. Folinstance, stainless steel inherently possesses corrosion resistance, chemical resistance, and heat resistancemaking it widely applicable across multiple industries. Titanium alloy, with its high corrosion resistance, can beused in environments with strong acids or bases. Additionally, titanium alloy is non-magnetic, suitable forapplications requiring non-magnetic materials.

- High Precision and Precision Machininghttps://heiautomation.com/

Tsubaki chains are manufactured with high precision using precision machining and measurement techniquesAll accessories are made of stainless steel, ensuring a long service life and strong corrosion resistance. Thehigh precision and precision machining guarantee the stability and reliability of Tsubaki chains duringoperation, reducing performance degradation due to friction and wear. - Easy Installation and Maintenancehttps://heiautomation.com/product/

Tsubaki chains are easy to install and maintain. During installation, it is crucial to minimize bending to preventdamage to the chain and to follow the manufacturer’s instructions for correct installation to ensure quality.Regular inspections of chain wear and locking strength are essential during use, with timely repairs for chainswith short service lives and replacement of damaged locking nuts. Additionally, regular cleaning of the chainprevents dust accumulation and reduces friction.6.Innovative Oil-Free Technology - Tsubaki chains feature the world’s first oil-impregnated bushing Lambda oil-free chain. This chain requires nolubrication for long-life operation, siqnificantly reducing chain replacement freguency and waste generation. ltalso maintalns a cl ean working environment and meets environmental reguirements by eliminating the needfor additional lubrication that could contaminate the equipment.https://heiautomation.com/contact-us/

Application Industries of Tsubaki Chains

1.Industrial Machinery

Tsubaki chains play a crucial role in the industrial machinery sector. Whether it’s the timing chain system inautomotive engines or conveyor machinery and material handling equipment, Tsubaki chains provide reliabletransmission solutions, Their high strength, durability, and corrosion resistance enable stable operation inharsh industrial environments for extended periods.

2.Chemical and Mining

In the chemical and mining industries, Tsubaki chains are also widely used. These industries often involve hightemperatures, corrosive media, and dusty environments, necessitating chains with excellent corrosionresistance and wear resistance. Tsubaki chains meet these requirements, maintaining stable transmissionperformance in these harsh environments over time.Textile and Electronics

Tsubaki chains are also widely used in the textile and electronics industries. Textile machinery requires a high-precision transmission system to ensure precise control of yarn and fabric, which aligns with the high precisionand stability of Tsubaki chains, In the electronics industry, Tsubaki chains are ysed in material handling andtransmission processes on automated production lines, enhancing production efficiency and quality.https://heiautomation.com/about/

4.Food Industry

Tsubaki chains are also widely used in the food industry. Due to the food industry’s high requirements forhygiene and safety, chains must exhibit excellent corrosion resistance and ease of cleaning. Tsubaki’s stainlesssteel chains and Lambda oil-free chains meet these requirements, maintaining cleanliness and hygiene duringfood production while ensuring the stability and reliability of the transmission system.5.Automotive Manufacturing

In the automotive manufacturing industry, Tsubaki chains are widely used in critical components such asengines, transmissions, and drive systems. Their high precision, high strength, and durability make themreliable transmission solutions in automotive manufacturing. Additionally, Tsubaki chains are easy to install andmaintain, reducing costs and time in automotive manufacturing processes

6.Agricultural Machinery

Tsubaki chains also play an important role in the agricultural machinery sector. Agricultural machinery needs towithstand heavy loads and operate in harsh environmental conditions, requiring chains with high strength anddurability, Tsubaki’s high-strength chains meet these requirements, providing reliable transmission solutions inagricultural machinery.7.Automation Equipment

With the continuous development of automation technology, Tsubaki chains are increasingly used inautomation eguipment, Whether it’s material handling and transmission systems on automated productiorlines or transmission systems in robot joints, Tsubaki chains provide high-precision, efficient, and reliabletransmission solutions, Their ease of installation and maintenance also reduces the operating costs andmaintenance difficulty of automation equipment.

8.Other lndustries

In addition to the above industries, Tsubaki chains are also widely used in other sectors. For example, inconstruction machinery, Tsubaki chains can withstand heavy loads and operate in harsh environments; in portmachinery, they are used for handling and transmitting large cargo; and in stage equipment, nursingmachinery, and escalators, Tsubaki chains’ low-noise function contributes to their widespread adoption.

Selection and Maintenance Tips for Tsubaki Chains

When selecting Tsubaki chains, users should choose the appropriate model and specification based on theirown needs and the usage environment. lt is also crucial to understand parameters such as transmissionefficiency, friction coefficient, and locking performance. Additionally, users should reasonably choose the chaininstallation method and verify the chain quality to prevent purchasing counterfeit or inferior products

When installing Tsubaki chains, users should follow the manufacturer’s installation guide and ensure correctinstallation to guarantee quality, During use, regular inspections of chain wear and locking strength areessential, with timely repairs or replacement of damaged components. Regular cleaning of the chain toprevent dust accumulation and reduce friction is also important.