Packaging is the glamorous “coat” and “armor” of a product.https://heiautomation.com/product/

Behind this elegance lies the packaging process that is efficient and safe, hidden within every second. Faced with various packaging materials, high-speed equipment, and increasingly strict environmental regulations, sensors are becoming the “intelligent role” behind the production line.

Let’s see how sensors deal with these challenges in packaging?https://heiautomation.com/

1、Reduce losses, start with precise perception

Is the low precision of container forming leading to a high waste rate? Yeshttps://heiautomation.com/contact-us/

High-precision and responsive photoelectric sensors can safeguard the high-speed continuous container forming process.

If the positioning of the filling containers is inaccurate or the sealing is abnormal, causing spillage inside the machine? Using photoelectric or ultrasonic sensors can ensure precise container positioning, real-time monitoring of the sealing status, and effectively avoid machine stops and the production of defective products.

Label misalignment or missed labeling? Special label detection sensors can identify https://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6jvarious label types, effectively preventing mislabeling and missed labeling.

Safety is guaranteed, and production becomes more reassuring.https://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6j

The equipment door and the protective cover form the first line of defense for the operators. Complianthttps://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6j

The safety door switch and door magnetic switch in accordance with the 13849-1 standard. They can achieve the highest SIL3 level of protection, effectively isolating hazardous areas and safeguarding human-machine safety.

Adapt to multiple materials, making the https://heiautomation.com/contact-us/production line more “inclusive”

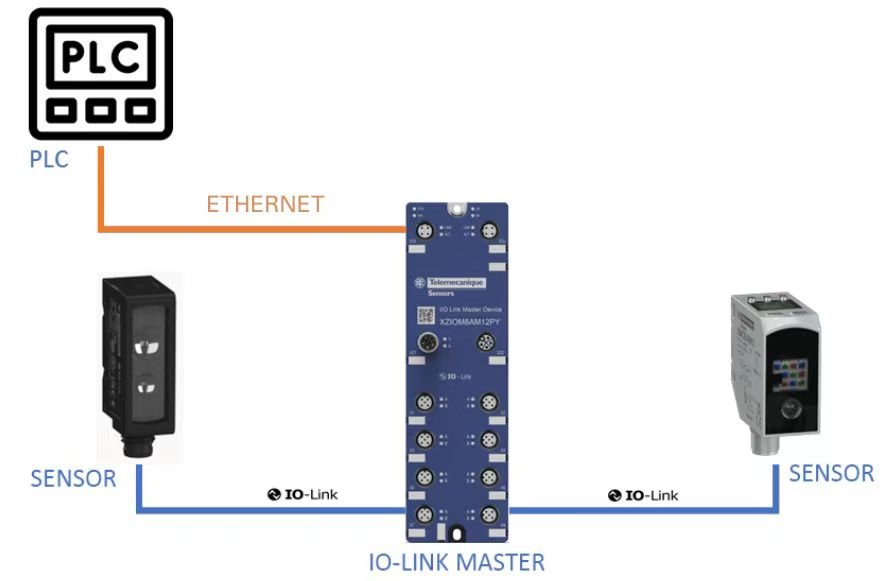

The sensor solution with multiple detection principles is the foundation for stable detection of various packaging materials; the application of I0-Link enables rapid parameter configuration for different packaging materials, achieving rapid production changes and reducing equipment downtime.

The Telemecanique sensor provides precise support for the packaging industry.

The V series of XU photoelectric sensors with a wide variety of types can stably detect packaging containers of various materials and different shapes:

- Ordinary paper boxes/cases, plastic boxes/cases: General typehttps://studio.youtube.com/channel/UC5jh-_J8N51BACPDqMnnT6Q/videos/short?filter=%5B%5D&sort=%7B%22columnType%22%3A%22date%22%2C%22sortOrder%22%3A%22DESCENDING%22%7D

хUMª, XUB - Slightly less reflective eco-friendly materials: Background suppression type XUM8/XUB8

- Transparent glass or plastic containers: Specialized for transparent materials XUMT or blue light XUMBAB*

Materials with extremely dark colors and poor reflectivity: High-performance blue car, light type background suppression XUK8AB* - Small volume/thin containers or folded cardboard boxes: Laser light source XUM*AL

- Color distinction: Multi-color recognition XUKC/XUMRAChttps://www.facebook.com/profile.php?id=100087291657130

The entire V series of label detection sensors can reliably detect and locate various types and materials of labels: 。 Common label: High-speed slot-type photoelectric switch “XUVE” 。 Transparent label: Slot-type ultrasonic sensor XUVU 。 Wet glue label in the storage bin: Reflective type photoelectric sensor XUM6

Color mark on the container: Color mark sensor XUMR

A wide range of safety detection products ensure the safety of personnel and operations:

- Observation window / monitoring door: Safety door magnetic switch XCSDMC/XCSDMP, RFID “safety switch XCSR

Guard door / fence: Safety door lock XCLSE/XCSLF

Emergency stop: Emergency stop pull cord switch xY2C

Why choose the Telemecanique sensor?https://heiautomation.com/product/

Rich varieties: Offers a wide range of detection principles and functional products, meeting the diverse needs of the packaging industry.

Easy integration: Ready to use upon installation, quickly integrating into existing production lines, enhancing equipment performance. Multiple new photoelectric sensors launched this year fully support IO-Link.

Reliable quality: Products have undergone rigorous tests and have obtained global mainstream market entry certifications such as CCC (China), CE (Europe), UL (USA), and CSA (Canada).

Flexible customization: Supports various configurations, suitable for various packaging https://www.instagram.com/sunny.zeng5/processes, helping to optimize the production line.