In semiconductor manufacturing, lithography machines https://heiautomation.com/product/are responsible for engraving circuit patterns onto wafers. During the wafer transfer process in the production sequence, precise positioning and accurate counting are key to the workflow. When developing manual lithography machines, manufacturers face multiple challenges: wafers stored in transfer boxes need to be picked up layer by layer, and it is necessary to ensure that each layer contains a single wafer to avoid stacking. The installation space at the bottom of the equipment is narrow, with the bottom-layer wafer being only about 20 millimeters away from the sensor. Conventional sensors cannot perform detection due to their blind zones. Meanwhile, it is also necessary to achieve real-time data collection and preventive maintenance of equipment while ensuring detection accuracy and cost-effectiveness, so as to guarantee the stable and efficient operation of lithography machines.

Baumerhttps://heiautomation.com/ U300: A Small-sized Powerhouse Breaking the Deadlock – Core Application Scenario: The “Smart Eyes” for Wafer Cassettes

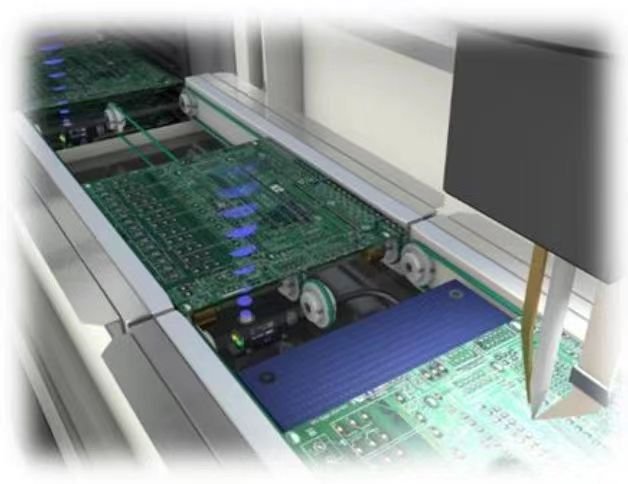

The Baumer https://heiautomation.com/contact-us/U300 ultrasonic sensor is installed at the bottom of the wafer cassette. It scans each layer of wafers from bottom to top through an acoustic cone, achieving two key functions:

- Distance https://heiautomation.com/about/detection and positioning: Precisely measure the position of wafers to ensure the accuracy of the picking path;

- Counting management: Avoid multi-wafer picking or missed detection through feedback of layer number signals.

Why Choose Baumerhttps://heiautomation.com/? Three Key Advantages Address Pain Points Directly

Compact Design + Ultra-Short Blind Zone

“A Tailor-Made Solution” for Narrow Spaces

Integrated compact housing with a blind zone of only 15mm (a level that similar productshttps://www.facebook.com/profile.php?id=100087291657130 on the market can hardly achieve), perfectly adapting to 20mm short-distance detection scenarios;

Bottom-mounted design does not take up extra space, conforming to the structural constraints of manual lithography machines.

Advantage 2: Flexible Adjustabilityhttps://heiautomation.com/ + Cost-Effectiveness – Maximized Cost Performance

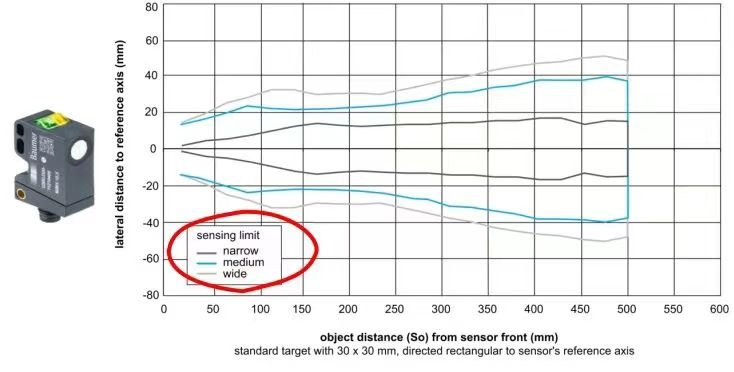

The sensing distance is adjustable from 15 to 500 mm, making it compatible with wafer cassettes of different specifications.

With a 0-10V analog output, it features an economical price and stable performance, which fits the needs of research and development as well as small-batch production.

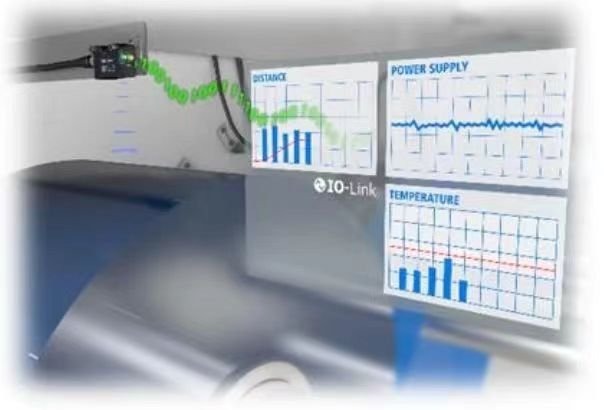

Advantage 3: Digital https://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6jInterface + Intelligent Maintenance – “Advanced Layout” for Future Factories

Integrated with an IO-LINK interface, it collects process data and diagnostic information in real time.

When paired with Baumer’shttps://www.facebook.com/profile.php?id=100087291657130 free BSS software, it enables preventive maintenance and reduces the risk of downtime.

U300 Highlights Analysis: Technical Details Reveal True Strength

The U300https://heiautomation.com/contact-us/ ultrasonic sensor boasts multiple core advantages and features numerous highlights in terms of technology.

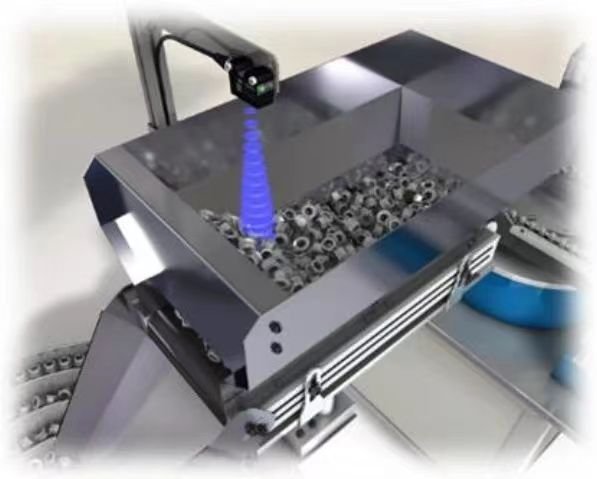

It supports adjustable acoustic cones and offers three modes: deep cone, medium cone, and wide cone, which can meet the detection needs of wafers of different sizes with strong anti-interference capability.

The sensor is integrated with dynamic averaging and interference https://www.facebook.com/profile.php?id=100087291657130filters, which can reduce the impact of environmental noise and make measurements more stable. Its built-in data processing function can reduce the computational burden on the PLC and improve the system response efficiency.

In addition, its measuring range of 500mm is the largest among similar products, making it adaptable to diversified production line designs.

The Baumer https://heiautomation.com/about/U300 has resolved the long-standing contradiction we faced between installation space and detection accuracy. In particular, its blind zone control and IO-LINKhttps://heiautomation.com/product/ function not only meet our current R&D needs but also lay the groundwork for future production line upgrades. Its cost performance has far exceeded our expectations!

— Industry Customer

“Driving the Future of Semiconductors with ‘Perception'”

Today, as semiconductor manufacturing advances toward nanoscale precision, sensors, known as the “industrial nerves,” are playing an increasingly critical role. With millimeter-level detection accuracy and flexible adaptability, the Baumer https://heiautomhttps://heiautomation.com/product-category/eh/ation.com/product-category/eh/U300 has become an “invisible guardian” in the wafer transfer process of lithography machines, injecting precise momentum into China’s semiconductor R&D and production.