Tires, as the core component of automobiles, the detection of surface defects directly affects driving safety and the reputation of manufacturing enterprises. Traditional manual detection is limited by subjective judgment and fatigue issues – with high rates of missed detections and false detections, it is difficult to meet the requirements of large-scale production. Baumerhttps://heiautomation.com/product/, with its deep expertise in industrial intelligent detection, has launched an AI detection solution for tire surface defects. With the advantages of precise identification and flexible adaptation, it provides an efficient and reliable qualityhttps://heiautomation.com/ control solution for the tire manufacturing industry.

Comprehensive and all-round, with no blind spots, and capable of accurately detecting over 100 defects.

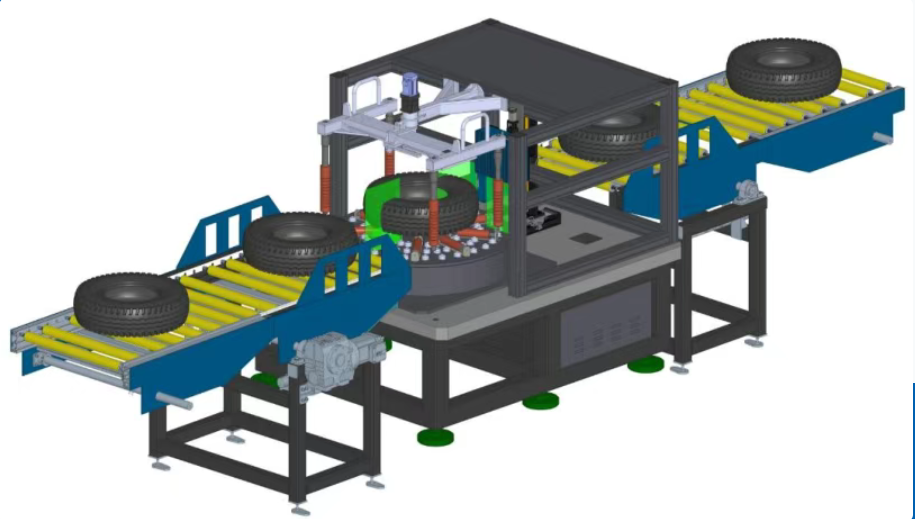

The complete coverage of surface inspection for componentshttps://www.facebook.com/profile.php?id=100087291657130 is one of the core highlights of this equipment. It can achieve non-stop inspection of key parts of the tire from the sidewall to the tread, easily handling over 100 common defects.

Visible defects such as bubbles, impurities, and missing glue on the sidewall surface, as well as label issues like missing glue on the logo, unrecognizable text, and inconsistent labels, can all be accurately captured. Blisters and misalignment of the patterns on both sides of the tread, edge defects, insufficient vulcanization in the middle, impurities and missing glue on the tire shoulders, and hidden problems such as exposed lines, cracks, and joint defects on the inner side and both sides, as well as excessive/insufficient width of the bead opening, exposed lines, and excessive skin on the bead, can all be detected. Quality risks can be completely https://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6jprevented from the source.

With enhanced core parameters, the detection accuracy has reached a new peak.

1、Stable collection:The VCXG.2-51Mhttps://heiautomation.com/product/ is equipped with high-performance high-definition visual components and features a high-resolution CMOS. Its imaging resolution can reach 2448×2048px. Combined with the optimized exposure control technology, the exposure time can be as short as 1µs. Even in the scenario of high-speed tire transmission, it can achieve stable acquisition without ghosting or frame loss, providing a clear and reliable image foundation for AI algorithms.

2、High accuracy rate:The VCXG.2-51M is equipped with advanced deep learning AI algorithms integrated within. After being trained on a large number of tire defect samples, it can accurately distinguish between minor defects and normal textures, significantly reducing the false detection rate.

Efficiently adapt to various scenarios and match large-scale productionhttps://heiautomation.com/about/

In terms of detection efficiency and adaptability, the VCXG.2-51M also performed exceptionally well.

Supports a production line transmission speed up to 60m/min, capable of completing hundreds of data collection and analysis operations per second. The detection efficiency has significantlyhttps://heiautomation.com/about/ improved compared to traditional manual methods, perfectly matching the production rhythm of large-scale production. Compatible with various detection modes such as full inspection and mixed inspection, it can be adapted to tires of different specifications ranging from 12 to 24 inches. Through the Web interface, detection parameters can be flexibly adjusted, and the detection switching for different tire models can be completed without complex debugging, greatly enhancing production flexibilityhttps://heiautomation.com/about/.

Three core advantages, making it the preferred choice for enterprises:Why do many manufacturing https://www.youtube.com/channel/UC5jh-_J8N51BACPDqMnnT6Qenterprises prefer the industrial camera products of B&R? One of the core reasons is the clear imaging and stable data acquisition without frame loss. The high-definition imaging and stable transmission of VCXG.2-51M ensure that the detection accuracy remains unchanged in complex production environments, making it impossible for tiny defects to hide. The high quality-to-price ratio is the key to its outstanding performance. A one-time investment can achieve long-term stable quality control, not only reducing economic losses caused by rework and recalls, but also lowering labor costs, bringing significant economic benefits to the enterprise.

In addition, it is compatible with mainstream industrial communication protocols such as PROFINEThttps://www.facebook.com/profile.php?id=100087291657130 and EtherNet/IP, and can seamlessly connect with production line systems, enabling real-time upload and traceability of detection data, helping enterprises build an intelligent quality control system.

Technology empowers industries, and Baumerhttps://www.instagram.com/sunny.zeng5/ remains committed to its original innovation mission.