Recently, the International Energy Agency released the “Energy and Artificial Intelligence” report. This report thoroughly analyzed the complex relationship between artificial intelligencehttps://heiautomation.com/product/ and energy, revealing a shocking trend: Under the prevailing trend of rapid development of artificial intelligence, by 2030, the power demand of global data centers will double compared to the current level, reaching approximately 945 terawatt-hours per year, which will exceed the annual electricity consumption of Japan.

According to the “Comprehensive Energy Consumption Report of Data Centers and Their Flexibility Forecast” released in January 2025, I predict that by 2030, the electricity consumption of data centers in China will account for 4.8% of the total electricity consumption of the entire society.

Against the backdrop of the rapid development of artificial intelligence, we should

figure out how to effectively meet its massive demand for energy

while not causing any impact on our energy system?

Danfoss, as a highly recognized solution provider in the industry, is actively assisting the data center sector in collecting and utilizing the heat that might otherwise be overlooked. Leveraging its one-stop solutions and profound industry experience, Danfoss is gradually transforming data centers into heat energy providers, thereby benefiting society and facilitating the green transformation of enterprises.

Data center heat recovery and reuse solutions and technologies

Capture waste heat from the data center and efficiently integrate it into the regional energy system, ultimately delivering it to nearby users with heat demands. Danfosshttps://heiautomation.com/, through its comprehensive solutions and product lines, helps users convert waste heat into recoverable heat.

Danfosshttps://heiautomation.com/about/ provides optimized software, heat recovery devices, energy transfer stations, heat pump solutions and energy-saving components for waste heat recovery solutions, ensuring that each step of the recovery process achieves better efficiency. Additionally, at the end-user application level of heating systems, whether for industrial, commercial, or residential living spaces, Danfoss can offer a series of heating solutions.

Danfoss heat recovery solutions

An experienced team of refrigeration and heating experts offers a complete product portfolio tailored specifically for regional energy applications, aiming to meet diverse needs.

We have launched a heat pump solution for district heating, which can significantly enhance energyhttps://heiautomation.com/ efficiency.

In terms of waste heat utilization, we provide optimized system control and distribution solutions.

From data centers to end users, we offer a series of integrated components that not only facilitate precise hydraulic balance but also ensure the high safety and durability of the system.

Danfosshttps://heiautomation.com/contact-us/ intelligent energy metering equipment monitors and manages energy consumption in real time.

“All Danfoss products are manufactured in accordance with the PED 2014/68/EU standard and comply with the ISO 9001/ISO 14001/IATF 16949 automotive industry standards.”

Danfoss offers a wide range of

thermal recovery solutions and products

- Heat Pump Solution

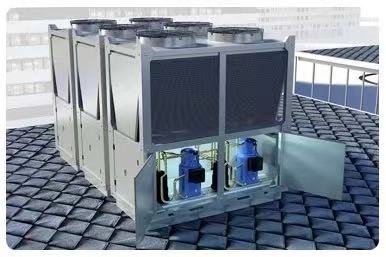

By utilizing existing external energy sources such as brine, fresh water or natural air as heat sources for heat recovery, the heat pump technology becomes an efficient and environmentally friendly way to promote the decarbonization of heating networks. The heat pump product portfolio includes various Danfosshttps://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6j products, such as highly efficient Danfoss scroll compressors, compact brazed plate heat exchangers with precisely controlled electronic expansion valves, etc. The integrated application of this series of high-performance components not only significantly reduces the application cost of heat pumps but also significantly shortens the investment recovery period.

Heat Recovery Module: The HRM (Heat Recovery Module) is a waste heat recovery system produced based on the 3D model designed by our R&D department. All core components, such as heat https://studio.youtube.com/channel/UC5jh-_J8N51BACPDqMnnT6Q/videos/short?filter=%5B%5D&sort=%7B%22columnType%22%3A%22date%22%2C%22sortOrder%22%3A%22DESCENDING%22%7Dexchangers, control valves, pumps, and measurement equipment, have been virtually connected through pipelines. Using automated machinery, the pipes are cut and welded according to the 3D drawings, ensuring the reliable quality of the system and shortening the delivery time. The unit is designed in a modular structure, making transportation and assembly more convenient. The heat exchange station includes an electrical wiring panel, which has undergone functional testing and can be put into use immediately after the power is connected on site.

- Hydraulic Balance

In the HVAC system, hydraulic balance plays a crucial role. It ensures that the internal temperature of the building is suitable and enables the system to operate https://heiautomation.com/about/efficiently. Once the hydraulic balance is disrupted, the number of user complaints will increase sharply, the operating cost of the system will rise dramatically, and long-term imbalance will inevitably accelerate equipment aging and shorten its service life.

Pressure differential and flow controller

The Virtus https://www.youtube.com/channel/UC5jh-_J8N51BACPDqMnnT6Qseries is a heavy-duty pressure differential and flow controller specially designed for regional heating and cooling applications. This series of products is suitable for primary pipelines and user heat exchange unit stations, ensuring the efficient and stable operation of the system.

- Regional Heating Valves

The electric regulating valve “can provide precise control for various buildings and applicationshttps://heiautomation.com/product/, thereby enhancing energy efficiency.”

- Ball Valve

Ball valves can control the opening and closing of connectionshttps://heiautomation.com/contact-us/ for each section, branch line, and end point of the pipeline network. They can isolate the system into different zones, allowing maintenance and repair in certain areas to be carried out smoothly without having to shut down or empty the entire system.

- Heat Exchangers

By utilizing the brazed, detachable and fully welded plate heat exchangers provided by Danfoss, the thermal transfer efficiency of heating, ventilation and air conditioning (HVAC) systems and district energy systemshttps://www.facebook.com/profile.php?id=100087291657130 can be significantly improved.

A region with efficient and sustainable urban energy utilization Solution

With the significant enhancement of environmental awareness in global cities, regional energy systems are increasingly becoming an important choice for many cities to promote sustainable development. By integrating renewable energy with local industrial waste heat resources, regional energy systems demonstrate the potential for efficiency and environmental friendliness.

However, as cities continue to expand in size and their demand for diversified energy sources keeps increasing, the regional pipeline network structure becomes increasingly complex. Ensuring the stable operation of the system to avoid malfunctions has become a crucial aspect. To address this challenge, Danfosshttps://www.facebook.com/profile.php?id=100087291657130 has introduced targeted solutions, aiming to help cities more effectively utilize renewable energy.

Based on a profound understanding of the fourth-generation (4G) regional energy technology, Danfosshttps://heiautomation.com/product/ can provide customers with a wide range of products and services. It effectively enhances the potential of regional heating and ensures the efficient and stable operation of the system.

In addition to possessing profound professional technical knowledge, Danfoss has also recognized that regional energy facilities have far exceeded the scope of merely providing heating and cooling services to end-users. They are also crucial drivers for cities to reduce carbon dioxide emissions and optimize energy consumption.

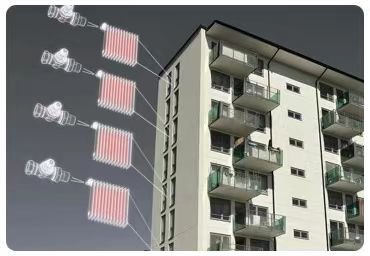

Heating pipeline network is safe, sustainable and scalable. Exhibition

The regional energy pipeline network demonstrates extremely high flexibility, enabling it to easily cover and provide heating for at least 30 to 40 buildings. This characteristic gives data centers the opportunity to transform into a new source of energy supply. When conditions are ripe, data centers can also further expand the scale of their existing pipeline network. To ensure that the pipeline network remains operating efficiently at all times, the entire system from the data center to the terminals, including its design and maintenance, must be in a balanced state. Whether it is building a new thermal energy pipeline network or integrating the data center into the existing network, Danfosshttps://heiautomation.com/festo-cylinders-versatile-applications-across-various-industries/ has professional capabilities to help you create an efficient regional heating pipeline network design solution.

Why does the data center industry need to adopt heat recovery solutions?

During the operation of data centers, a large amount of waste heat is generated by IT equipment (such as servers). Traditionally, this heat was often discharged into the air. However, the heat generated by the cooling system of the data center can also be used to heat nearby buildings. Therefore, recovering waste heat provides a huge opportunity https://heiautomation.com/product-category/eh/for data centers, making them more sustainable.