Driven by the global https://heiautomation.com/product/acceleration of digitalization and the “dual carbon” goals, data centers are currently facing unprecedented challenges – such as how to ensure the stable operation of high-density computing power while reducing the average energy utilization efficiency and improving energy efficiency. Liquid cooling technology has become the inevitable choice for data center energy conservation. However, the efficient operation of liquid cooling systems cannot be achieved without precise automated monitoring and intelligent control.

Ifm has been deeply https://heiautomation.com/engaged in the field of data center liquid cooling, providing automated solutions covering the entire range from CDU (cooling distribution unit), immersion cooling, to cooling towers, to help data centers achieve efficient, stable and green operation!

Direct chip cooling is an importanthttps://www.facebook.com/profile.php?id=100087291657130 form of liquid cooling technology. The cooling liquid directly contacts the CPU and GPU and other heat-generating components through the cooling plate, and then is circulated for cooling by the CDU.

Challenges

The fluctuations in coolant pressure, temperaturehttps://heiautomation.com/about/, and flow parameters

affect the cooling efficiency of the chip

Pump failure and pipeline leakage result in unplanned shutdowns Machine

It is difficult to accurately monitor the quality changes of the coolant in real time.

The traditional analog signals are prone to electromagnetic interference and have insufficienthttps://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6j measurement accuracy.

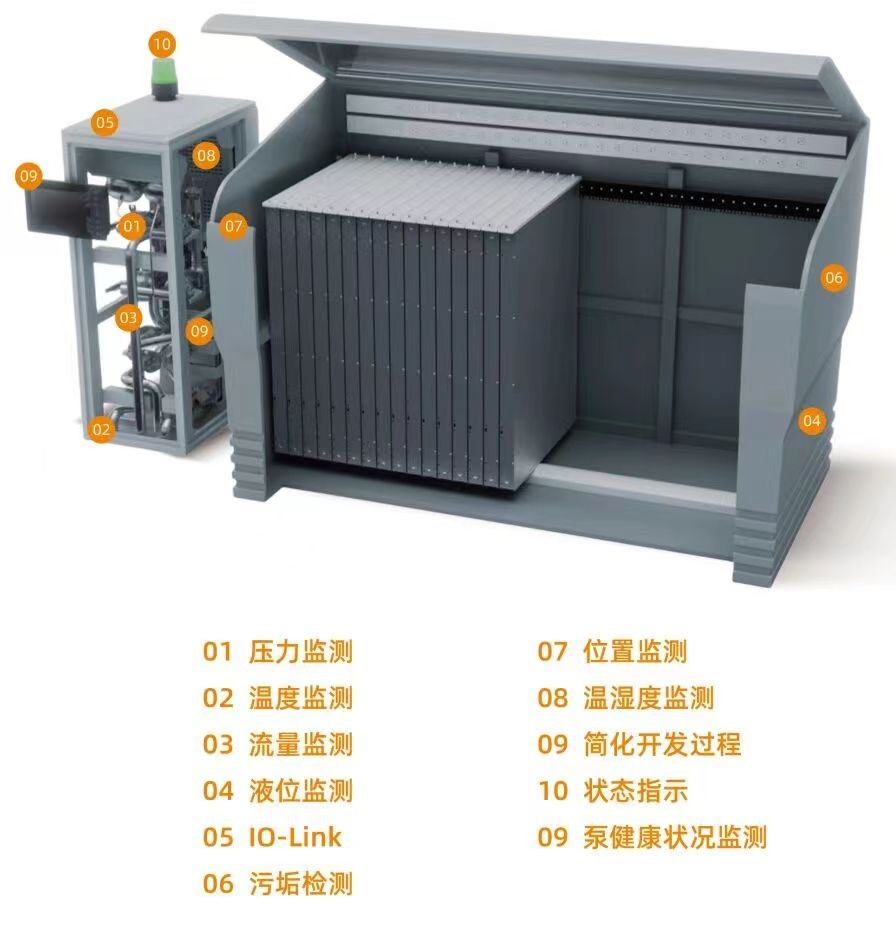

IFM Solution Pressurehttps://heiautomation.com/contact-us/ Monitoring: Real-time monitoring of pipeline pressure, detecting leaks or filter blockages. Temperature Monitoring: Precise temperature control to ensure equipment efficiency. Flow Monitoring: Continuous high-precision monitoring to promptly detect pipeline abnormalities. Liquid Level Monitoring: Ensuring stable coolant supply and avoiding pump dry running. Contamination Detection: Real-time monitoring of coolant conductivity to promptly alert of medium contamination. Pump Health Monitoring: Achieving predictive maintenancehttps://studio.youtube.com/channel/UC5jh-_J8N51BACPDqMnnT6Q/videos/short?filter=%5B%5D&sort=%7B%22columnType%22%3A%22date%22%2C%22sortOrder%22%3A%22DESCENDING%22%7D through vibration monitoring.

Immersion cooling immerses https://heiautomation.com/about/the entire server or electronic components in an electrolytic cooling liquid tank. The cooling process absorbs heat directly from the components, ensuring a uniform cooling effect. The compact design reduces the floor space required for the data center.

Challenges

· All components must be completely submerged. Abnormal liquid level will lead to hotspotshttps://heiautomation.com/contact-us/ or overflow.

The quality of dielectric cooling fluid has an impact on the efficiency of heat dissipation. Big

The opening and closing status of the outer cover of the cooling tank needs to be monitored in real time.

Changes in environmental temperature and humidity https://www.facebook.com/profile.php?id=100087291657130affect the system performance.

ifm solution

Level monitoring: Ensure uniform cooling and prevent overflow from damaging equipment

Position monitoring:

Full-metal inductive proximity switch ensures the closure of the outer cover of the cooling tank

Real-time monitoring of coolant

Contamination detection:

Quality and contamination status

Temperature and humidity monitoring:

Precise monitoring of environmental parameters to ensurehttps://www.instagram.com/sunny.zeng5/ system performance

The cooling tower is used to discharge heat into the https://www.facebook.com/profile.php?id=100087291657130atmosphere. Temperature fluctuations can affect the performance of servers and critical infrastructure.

Challenges

Mechanical components such as fans and pumps malfunctioninghttps://heiautomation.com/product/ leading to unexpected downtime

Water quality conductivity affecting cooling efficiency, scaling and corrosion risks

Abnormal liquid levels causing dry running of pumps or overflow

Difficulty in precisely controlling the supply water and drainage volume – ifm solution

Liquid level monitoring: Real-time and accurate monitoring of liquid levels in the cold water collection tank and hot water distribution tank

Monitoring of fan and pump health: Preventing catastrophic equipment failures

Flow monitoring: Precisely monitoring to avoid excessive water usage

Contamination detection: Ensuring water quality remains within the optimal range

Temperature monitoring: Ensuring that the temperaturehttps://heiautomation.com/about/ of the cooling fluid meets the standard before recirculation

Pressure monitoring: Early detection of blockages, leaks and sediment accumulation

Selected Star Products

The 10-Link master station with IP67 protection rating is used for PLChttps://heiautomation.com/festo-cylinders-versatile-applications-across-various-industries/ and industrial Internet of Things (IoT) connections. It directly communicates with your SCADA, MES, ERP, CMMS, etc. systems, and can also send information to the PLC to achieve easy control.

VVB Series IO-Link Vibration Sensors

Accurate condition assessment, automatic alerts, and root cause analysis can be performed without complex operations. Analysis

HMI for industrial applicationshttps://heiautomation.com/about/

Display controller

IFM operation control system support

Help with industrial 4.0 equipment upgrade

TCC series temperature sensors

Incorporate temperature drift monitoring and

diagnostic functions, suitable for

extremely demanding operating environments

Integrated LDL series conductivity sensors

The new LDL features advanced conductivity measurement https://heiautomation.com/contact-us/technology, integrating the sensor and evaluation functions into a compact housing.

PL1/PL5 Series Parallel Pressure https://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6j/shortsTransmitter

The PL1/PL5 series parallel pressure transmitter can be applied to high-viscosity media and media containing suspended solids, effectively avoiding blockage.

Ultrasonic Flowmeter: SU

The SU series of Puresonic ultrasonic https://heiautomation.com/flowmeters can accurately measure water or oil and other

media. The maximum measurement range is for media with a temperature up to 100℃.

SMF series electromagnetic https://heiautomation.com/flowmeters

The SMF series electromagnetic flowmeters can simultaneously monitor 4 processes

Parameters: instantaneous flow, cumulative flow, temperature and conductivity. M12 quick connection port and support Chinese interface

LR Series Guided Wave Radar Sensing

With its modular transmitter design, it demonstrates https://heiautomation.com/outstanding performance in industrial automation and harsh environment applications

LMC series point liquid level sensor

Thanks to its reliable performance, it effectively enhanceshttps://heiautomation.com/about/ the stability of the process flow. Even when dealing with adhesive media, there will be no bridging or false triggering problems.

The PA series pressure transmittershttps://www.facebook.com/profile.php?id=100087291657130 feature a compact housing design, making installation easy.

The TA2 series temperature transmitters are compact transmitters designed for industrial applications. They offer high stability and can withstand pressures up to 400 bar.

Core Technology Highlightshttps://www.facebook.com/profile.php?id=100087291657130

10-Link digital communication is plug-and-play, shortening the debugging time and eliminating analog-to-digital conversion errors. The digital communication protocol is not affected by electromagnetic noise, which is particularly important in data centers with high noise levels.

Predictive Maintenance: By integrating multi-dimensional data such as vibration, temperature, and pressure, it can monitor five major issues of the machine in real time: impact, fatigue, friction, severity, and temperature, and issue early warnings for faults.

IoT Industrial Internet of Things: Through the Moneo platform, data from sensors to the cloud is connected, enabling real-time process improvement and enhancing OEEQ (Overall Equipment Effectiveness).

Liquid cooling technologyhttps://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6j/shorts is the key to breaking through the energy efficiency bottleneck in data centers. #ifm offers a sensing solution covering the entire range of CDU, immersion cooling, and cooling towers, helping liquid cooling systems achieve precise monitoring, predictive maintenance, and efficient operation.