Equipment manufacturers are setting new standards and benchmarks for automation systems. Intelligent sensor technology needs to ensure ultra-high reliability and system availability to lay the foundation for this. As an experienced industrial sensor manufacturer, Leuze https://heiautomation.com/product/has extensive expertise in sensor applications in the wood processing industry. Our innovative products provide efficient solutions for the specific challenges of the wood processing industry.

Leuzehttps://heiautomation.com/ Components’ Innovative Solutions

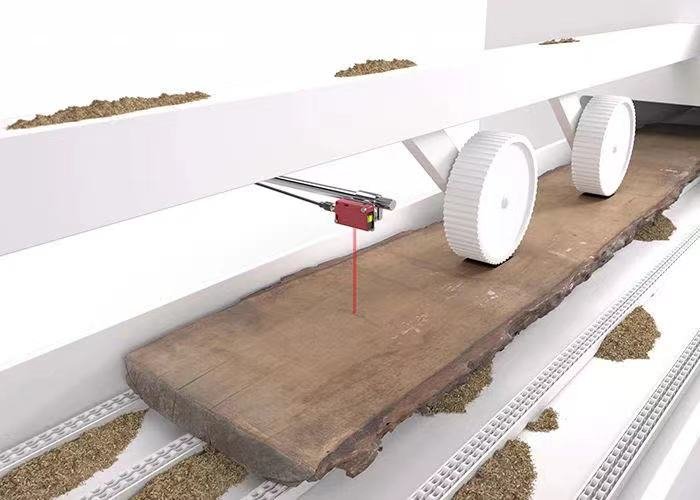

Steadily perform detection of presence and absence as well as precise positioning function.Is there any detection of the objects in the feeding section?

Requirement: Between the processing https://heiautomation.com/about/stations, the wood components are transported via the conveyor line. For

To achieve precise control of the transportation and independent processes, precise positioning detection must be carried out on the plates.

Solution: The HT 46C or HRT8 serieshttps://heiautomation.com/contact-us/ optical sensors include diffuse reflection sensor models. They have a wide detection range and can reliably detect even when there are differences in the structure or color of wood boards and sheet materials.

Are there any detections of objects in a dirty environment?

Requirement: During the wood processing process, sensors https://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6jthat are not sensitive to dust and dirt must be used to detect the wood objects for process control.

The 46 and 49 series diffuse reflection sensorshttps://heiautomation.com/contact-us/ have high functionality and several advantages. The light beam is concentrated and the energy is strong, enabling stable object detection even in environments with severe dust. The enhanced dust-proof type (such as HT46C.E) has better anti-fouling ability and is more durable and sturdy.

Object detection in dirty environments

Requirement: Regardless of whether the surface of the wooden board is covered with dust or dirt, it is necessary to achieve stable recognition to ensure the reliable startup of automated sawing or processinghttps://heiautomation.com/about/ equipment.

Solution: Capacitive sensors of M18 or M30https://heiautomation.com/about/ specifications for detection

The detection distance can reach up to 60 millimeters. It can be easily integrated into the conveying system and can easily

detect wooden boards, without being affected by the color of the wooden boards or wood chips. The LCS1 series with a metal casing is very sturdy, and the standard LCS2 design with a more economical plastic casing can also be chosen.

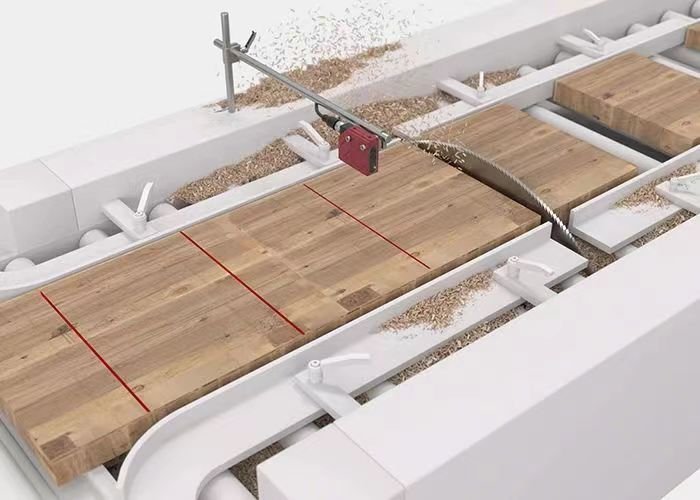

Mark detection and cutting control

Requirement: When automatically cutting different types of wood,

it is necessary to reliably detecthttps://heiautomation.com/contact-us/

the specific color of the mark in order to cut different lengths

Mark detection and cutting control

Requirement: When automaticallyhttps://heiautomation.com/product/ cutting different types of wood,

it is necessary to reliably detect

the specific color of the mark in order to cut different lengths

Solution: LRT8 fluorescent sensor. It can detect color marks on any wood surface for sawing control. It uses ultraviolet light and has extremely strong anti-fouling capabilities.

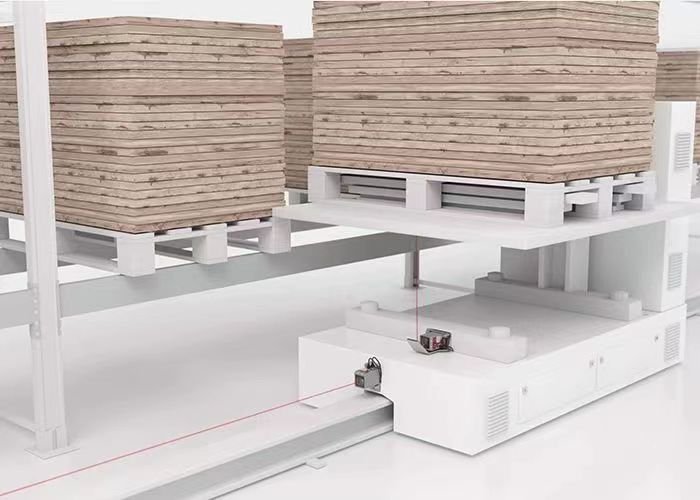

High-level shelving warehouse positioning

Requirement: When automatically transportinghttps://www.youtube.com/watch?v=vjpjyv7nYGQ sheets or stacks of wood within the warehouse, the transfer vehicle or stacker crane needs to be accurately and rapidly positioned. This requires the sensors to simultaneously have sufficient detection distance and positioning accuracy.

Solution:

AMS100 or AMS300https://www.youtube.com/channel/UC5jh-_J8N51BACPDqMnnT6Q laser positioning system

Can provide a measurement range of up to 300 meters. It has numerous interfaces that can be connected to PLCs. It is sturdy and durable.

Leuze Security Solution

Reliable security access control prevents personnel injuries and shortens downtime.

Entrance and exit protection in the long-door crane area

It is required that the automated area of the crane needs to be protected to ensure smooth operation. Therefore, safety sensors are used to minimize the impact on the entrances and exits.

Solution: The MLD safety grating is installed at the protected position of the UDC device column. It can be configured with 2, 3 or 4 beams, with the maximum distance reaching up to 80 meters, enabling protection for a large area. At the corners, reflective columns can be selected to achieve beam deflection. For more flexible installation methods, the SLS 46C https://heiautomation.com/product/beam safety type beam photoelectric sensor can be used to build a multi-beam system.

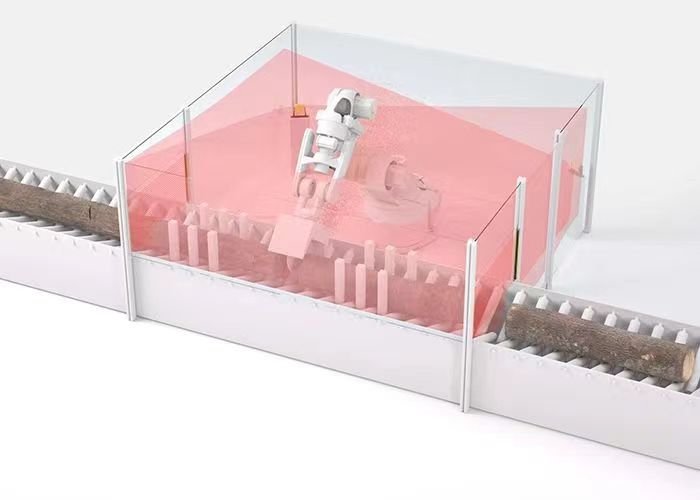

Cutting entrance and exit protection

Requirement: Design an additional restart interlock to prevent accidents from occurring in the monitoring area, including during the cutting process. This cutting environment requires extremely high dust prevention.

Solution: The LBK security radar system has strong anti-fouling capabilities. The area monitoring of the sawing unit requires at least two devices. Depending on the size of the device, one LBK controller can connect up to six sensorshttps://www.facebook.com/profile.php?id=100087291657130.

Requirements for entrance and exit protection in the maintenance area: Personal https://heiautomation.com/festo-cylinders-versatile-applications-across-various-industries/safety is of utmost importance in factory automation. Sensors must monitor the status of the system entrances and exits (such as maintenance doors) during operation.

Solution: Compact security door locks of the L100 https://heiautomation.com/product-category/eh/series or sturdy door locks of the L300 series are suitable for entrance and exit protection. All protection locking devices are equipped with OSSD output.