In the food and beverage industry, cost control and production ehttps://heiautomation.com/product/fficiency are the lifelines of enterprises. The precise measurement of raw materials and the strict control of process parameters directly affect product quality, loss control, and profit margins. Traditional single-function flow meters are no longer able to meet the urgent needs of modern factories for real-time monitoring of multiple parameters and lean management. Enterprises urgently need more intelligent solutions that can simplify processes, reduce equipment investment, and obtain more comprehensive process data to achieve true cost reduction and efficiency improvement. Endress+Hauser’s hygienic electromagnetic flowmeter “Promag H” has become the “key player” in solving this problem.

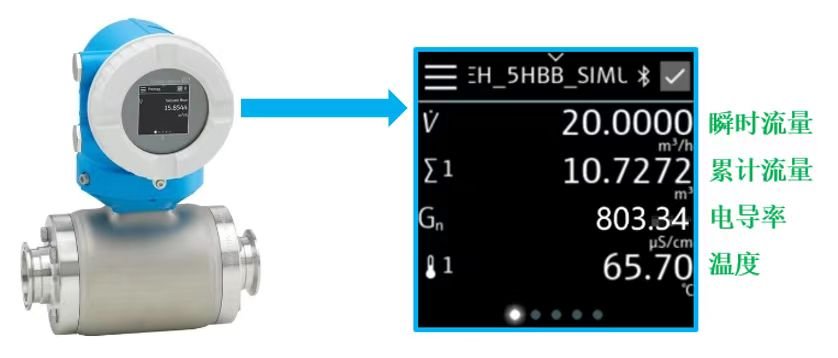

Multi-function in one machine: A production tool with full parameter control.

The Endershaus Promag H series electromagnetic flowmeter has completely overturned the single-function positioning of traditional instruments, transforming into a versatile player in the production process:https://heiautomation.com/

Flow measurement: Bidirectional flow measurement capability, minimum conductivity

Supporting liquids with a conductivity as low as 5uS/cm, covering juices, beers, wines, dairy products and other types of food fluids.

Conductivity monitoring: Real-time detection of changes in liquid conductivity, with a measurable range of 5 to 150,000uS/cm, providing key data support for product proportion consistency,https://heiautomation.com/contact-us/

Separate setting of conductivity measurement points, helping enterprises reduce instrument procurement costs and installation and construction costs.

Temperature synchronous acquisition: Tolerating medium temperatures ranging from -20℃ to +150℃, directly participating in process control, synchronous transmission of temperature data, real-time monitoring of process process dynamichttps://heiautomation.com/about/ changes.

One instrument can accomplish the task that previously required the collaboration of multiple devices.

This simplifies the system structure and reduces procurement and maintenance costs. With a high precision of ±0.2%, it ensures the accuracy of the ingredients, and simply by reducing raw material waste, it can save considerable costs for the https://heiautomation.com/enterprise.

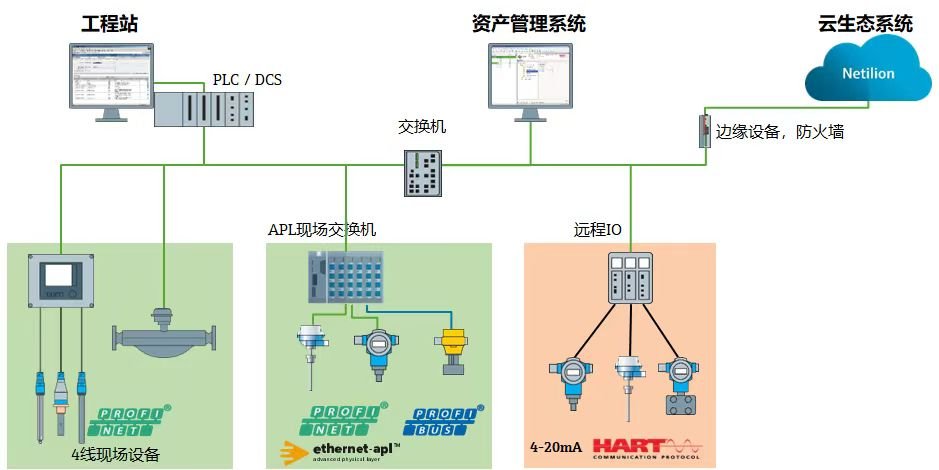

Full Protocol Compatibility: Creating Seamless Connectivity for Smart Factories

In the era of Industry 4.0, the interconnection of equipment is the foundation of a smart factory.

Endesmous Electromagnetic Flow Meter provides industry-leading solutions. Take

Interface H-1

This interface completely breaks down informationhttps://heiautomation.com/contact-us/ silos.

In addition to the conventional 10-Link communication function, it also possesses the following rich protocol standards:

Basic communication: Supports 4-20mA + HART transmission and is compatible with traditional control systems.

Industrial bus: Integrates mainstream field buses such as PROFIBUS DPQ/PA, FOUNDATION Fieldbus.

Ethernet architecture: Supports Profinet, EtherNet-APL, EtherNet/IP industrial Ethernet https://studio.youtube.com/channel/UC5jh-_J8N51BACPDqMnnT6Q/videos/short?filter=%5B%5D&sort=%7B%22columnType%22%3A%22date%22%2C%22sortOrder%22%3A%22DESCENDING%22%7Dprotocols to achieve high-speed data transmission.

Advanced interface: Equipped with RS485 (supports Modbus) and OPC-UA interface, connecting the data channels between IT and OT layers.

This all-protocol coverage capability enables enterprises to easily achieve system integration at any stage of automation construction and avoid duplicate investments due to incompatible communication protocols.

Health Certification: International Standards Build a Safety Barrier

In today’s era where food safety is receiving increasing attention, the Endress Hauschau https://heiautomation.com/about/Health

Series electromagnetic flowmeter, with the dual authoritative certifications of 3A and EHEDG, jointly

constructs a trustworthy protective barrier.

3A Certification: Compliant with the 3-A hygiene standards in the United States, meeting the basic hygiene requirements for food equipment.

EHEDG Certification: Passed through rigorous tests by the Europeanhttps://heiautomation.com/contact-us/ Hygiene Engineering and Design Organization, this certification represents the highest standard for hygiene equipment globally (EHEDG).

The core value of EHEDG certification lies in its unconventional hygiene design requirements: The certification requires that the equipment must ensure no dead corners, be fully drainable, withstand CIP/SIP cleaning (including up to 150℃ high-temperature steam sterilization), and have a surface roughness of Ra < 0.8um. This design

Completely eliminated the potential risks of microbial growth, benefiting beer, grains and oils, and dairy products. Taste

Compensation.

High-standard products such as infant formula foods provide safetyhttps://www.facebook.com/profile.php?id=100087291657130 guarantees.

Zero-contact debugging: The new era of intelligent operation and maintenance

Say goodbye to the cumbersome operation of traditional opening andhttps://heiautomation.com/contact-us/ debugging. Endress+Hauser brings a revolutionary debugging experience

Bluetooth/WIFI wireless debugging: Remote operation via mobile phone or tablet, avoiding the hygiene contamination risk caused by opening the cover

Ethernet remote access: Engineers can complete the diagnosis and parameter setting of the entire line of instruments in the control room

Touchscreen external operation: Backlight display + touch control, no need to open the equipment cover

Separate display unit: The display module can be installed at a position convenient for observation, achieving flexible monitoring

These advanced debugging methods not only shorten the equipment maintenance time by more than 50%, but also avoid the batch contamination risks caused by opening the cover during production, and are particularly suitable for aseptic production https://www.facebook.com/profile.php?id=100087291657130environments.

Heartbeat Technology: Intelligent Guardian for Predicting the Future

Heartbeat Technology is the core technology deeply embedded in Endershaus Flowmeters. It senses the process measurement of pulses and creates three major customer value propositions.https://heiautomation.com/product/

Self-calibration function: Automatically performs instrument performance testing on a regular basis, generates traceable verification reports, and meets the management requirements for measurement equipment stipulated by ISO9001 quality system.

Predictive maintenance: Real-time monitoring of key parameters such as electrode wear and liner condition, sending out warnings before faults occur to avoid unplanned downtime.

Compliance guarantee: Automatically records calibration data, providing complete documentation for audits by regulations such as FDAGMP, reducing the workload of certification preparations.

This technology transforms the maintenance strategy from “repair after failure” to “predictive maintenance”. According to actual application data, it can reduce the maintenance costs for customers and improve equipment availability.

With precise control down to every drop and safe protection at every moment – Endress+Hauser sanitary electromagnetic flowmeters are operating stably on production lines of thousands of food enterprises worldwide.

From CIP cleaning in dairy production lines to filling lines in breweries, from juice blending systems to seasoning production, their pressure-loss-free energy-saving design helps enterprises reduce energy consumption; maintenance-free structure saves labor costs; multi-parameter measurement optimizes raw material utilization; heartbeat technology makes unexpected shutdowns a thing of the past.

When cost control meets food safety, Endress+Hauserhttps://heiautomation.com/product/ uses technological innovation to provide a perfect solution. If you need any assistance, please feel free to contact the local sales center of Endress+Hauser. We are more than happy to help you choose the optimal solution.