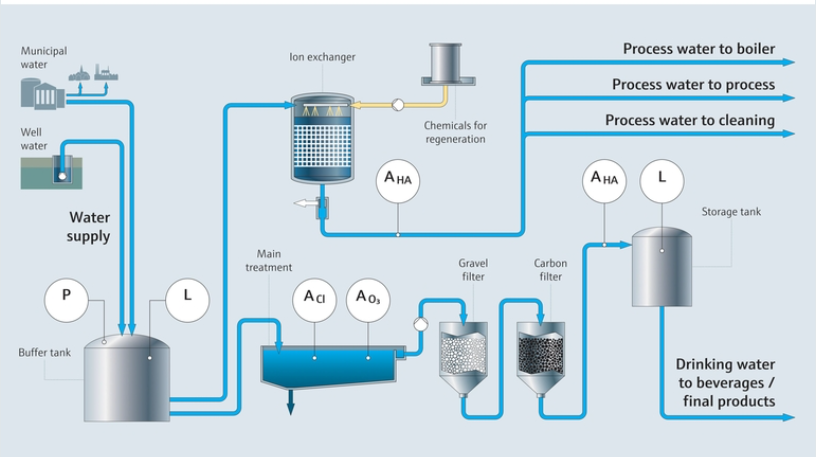

Water quality management and regulatory https://heiautomation.com/product/compliance are of utmost importance in beverage production, as they directly affect product safety, consistency of taste, and compliance with health standards. Clean and properly treated water sources can effectively prevent contamination and protect production equipment. Adhering to regulations not only avoids legal risks but also contributes to sustainable development, making water resource management a core component of a high-quality beverage production system.

Reduce manual analysis – Intelligent sensors and real-time monitoring technologies effectively complement manual sampling

Ensure compliance – Automated data recording simplifies auditing and reporting processes

Reduce risks – Predictive maintenance reduces downtime, ensures waterhttps://heiautomation.com/ quality and enhances process efficiency

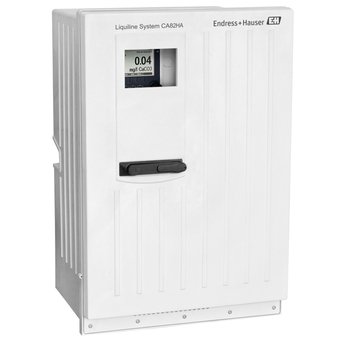

Water Quality Hardness Analyzer

Colorimetric measurement system, online monitoringhttps://www.facebook.com/profile.php?id=100087291657130 of process water, low detection limit monitoring.The Liquiline System CA82HA enables on-line colorimetric analysis of low-concentration hardness parameters. Its detection limit (LOD) is as low as 0.02 mg/L. This system helps operators enhance production efficiency by reducing issues such as fouling in heat https://www.facebook.com/profile.php?id=100087291657130exchangers, and can prevent damage to capital-intensive equipment like turbines. With reliable capabilities for analyzing pure water and ultra-pure water, this analyzer ensures product quality in industries such as steel, papermaking, and tires.

The Liquiline System CA82HA enables you to monitor the total hardness of water with a low detection limit. It is mainly applicable to the following application scenarios:

Monitoring of boiler feedwater, condensate and water vapor circulation

Analysis of Pure Water and Ultra-Pure Water

Monitoring of reverse osmosis and seawater desalination systemshttps://heiautomation.com/product/

If you need to monitor the water treatment process or require a wider measurement https://heiautomation.com/contact-us/range, please choose the Liquiline System CA80HA for water hardness analysis.

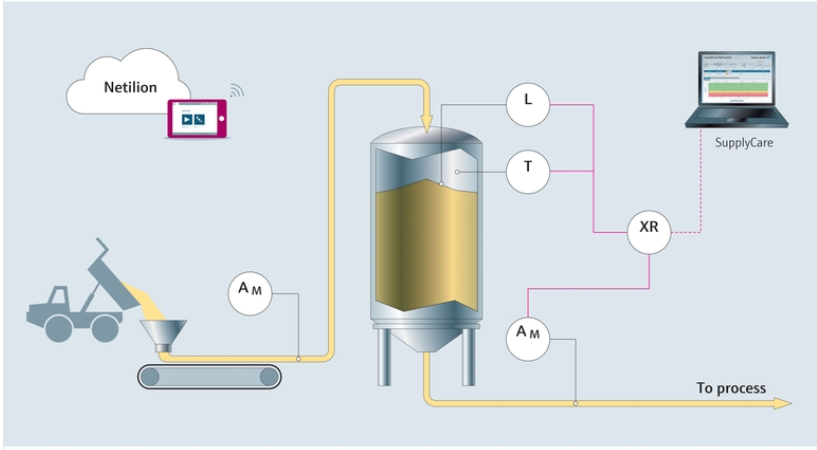

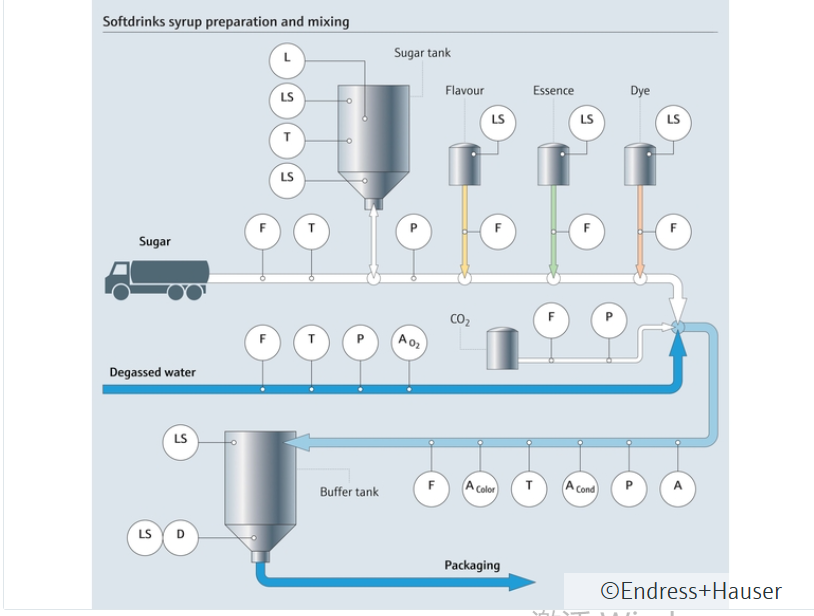

Advanced material flow control technology https://heiautomation.com/about/can optimize product quality, reduce waste and ensure continuous and stable operation.Preventing quality loss and avoiding resource waste. Advanced technologies empower manufacturers to conduct real-time and precise monitoring of key storage conditions. Through intelligent measuring devices and digital tools, they can comprehensively control humidity, temperature, and inventory status, ensuring that every product meets strict standards for quality, safety, and efficiency.

Preventive measures – The intelligent temperature and humidity control system effectively prevents the deterioration and agglomeration of materials.

Precise inventory insight helps optimize warehouse planning.

Bluetooth connection technology eliminates the need for manual climbing operations, ensuring real-time and transparent data transmission.

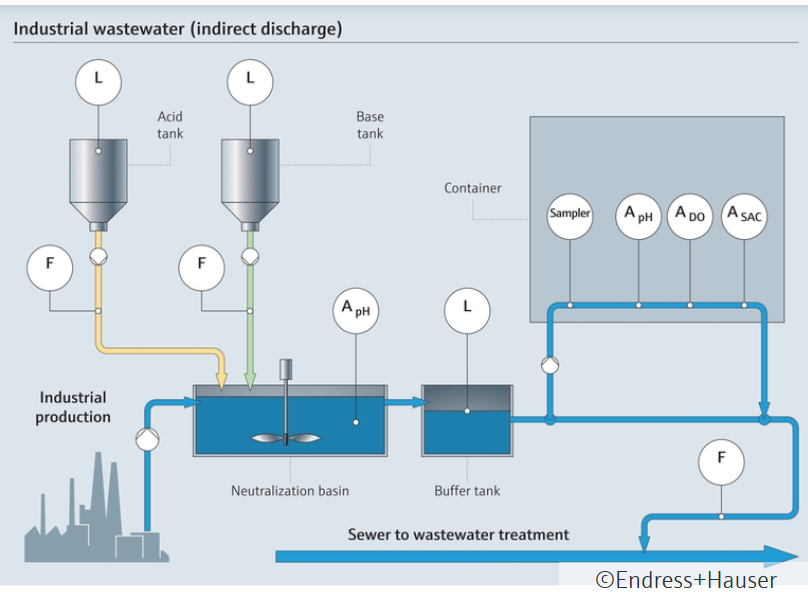

Improve the treatment efficiency of industrial wastewaterhttps://heiautomation.com/

Output useful process information to achieve data-based decision-making, and also be a responsible ESG (Environmental Protection, Social Responsibility, Corporate Governance) partner. We help users achieve sustainable development goals, improve operational efficiency, and act responsibly – throughout the entire process from wastewater prevention to emission monitoring:

Select the appropriate measurement techniques to reduce the amount of wastewater generated during food processing

Reduce the usage of rinsing water, shorten the switching time between products and cleaning operations, save costs and protect the environment

Monitor and record the amount of wastewater to ensure efficient utilizationhttps://heiautomation.com/contact-us/

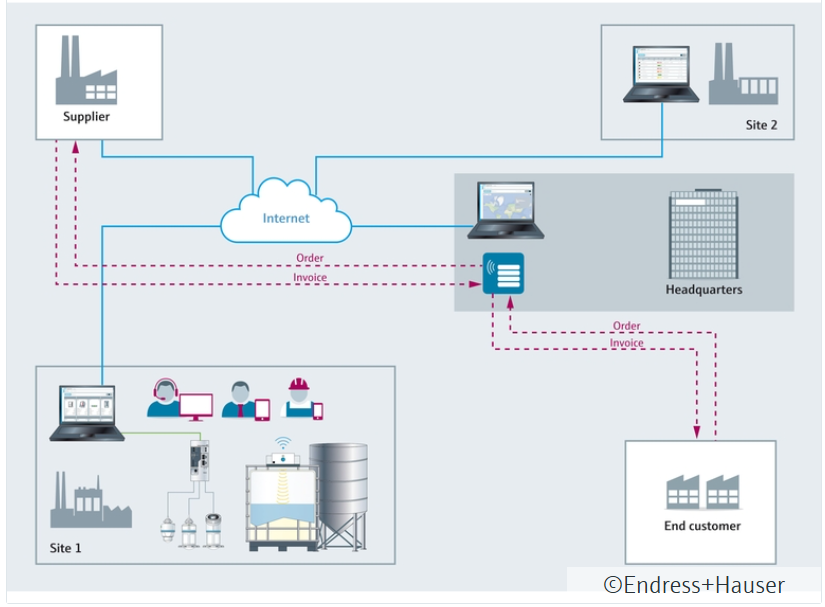

Enhance the sustainability and efficiency of the supply chainhttps://heiautomation.com/product/

Make local and decentralized inventory information transparent to ensure the availability of materials, thereby improving the efficiency and sustainability of the supply chain. Based on material requirements and transportation routes, optimize the delivery plan.

Ensure the availability of materials and maintain complete transparency of information, strengthen inventory control

Simplify delivery and logistics planning, reduce costs and workload

Be able to query data anytime and anywhere, whether at the workstation or during transportation and movementhttps://www.instagram.com/sunny.zeng5/

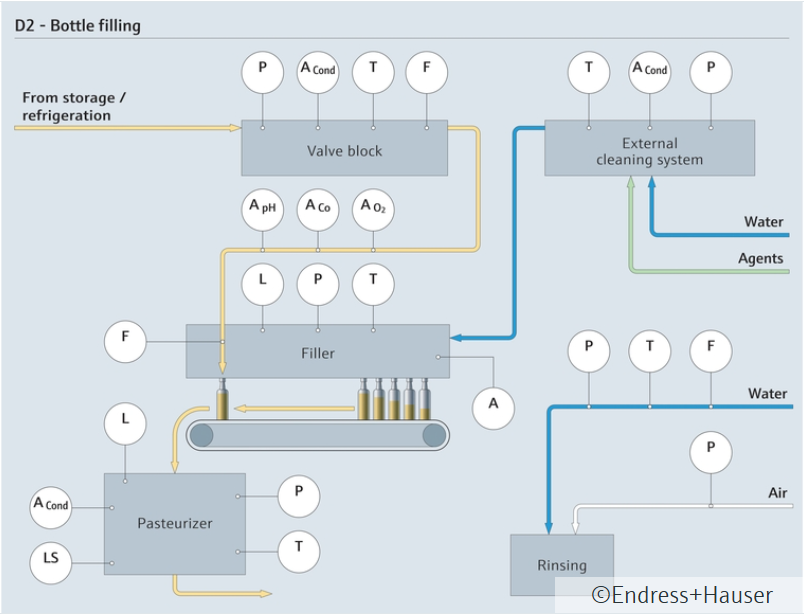

Reduce the complexity of filling applications

Ensure a shorter time to market through standardization, and improve various production processes. Provide all necessary documents and certificates to ensure compliance with food safety and quality standards.

Unified asset management, with plug-and-play functionality for instruments

Easy system integration, quick instrument debugginghttps://heiautomation.com/product/

From the fully transparent installation site to open-ended seamless query of equipment information

Ensure normal food preparation time

Integrate production facilities seamlessly https://heiautomation.com/product/and uniformly to ensure high productivity. Utilize advanced digital software, automation technologies and standardized communication protocols to enhance operational efficiency, ensure stable and consistent data, and improve the scalability of the production line.

Interoperability: Ensure that all devices and systems are compatible with each other

Sustainability: Adopt a more intelligent system design to achieve energy-saving production and reduce waste

Traceability: Visualize the entire production process to improve product quality and safety

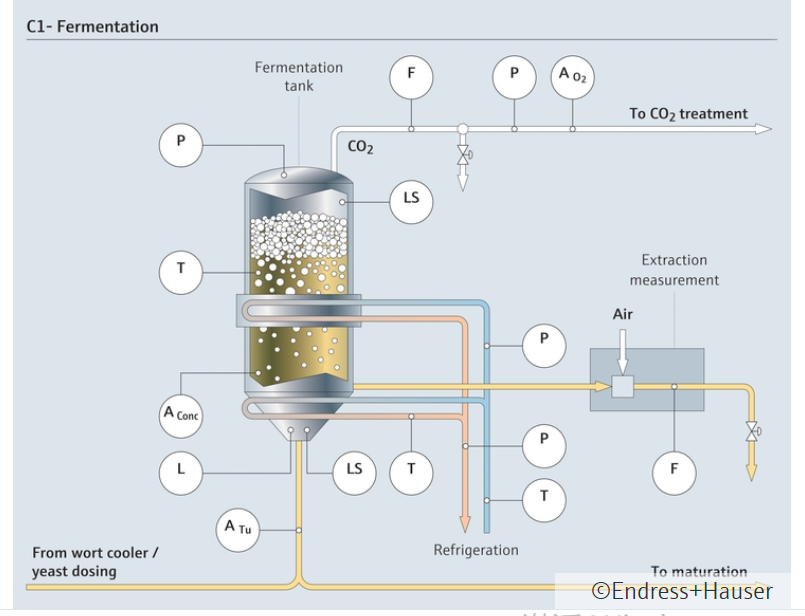

The fermentation process information is fully transparent.

The full transparency of the fermentation process ensures high product quality and yield in beer brewing.

24/7 information is transparent, reliable and effectivehttps://heiautomation.com/about/

Optimize to enhance the production efficiency of fermentation tanks

Improve cooling efficiency and achieve energy conservation

Efficiently respond to changes in yeast activity

Shorten the time for manual sampling and reduce workload