On the precise stage of automated manufacturing,https://heiautomation.com/product/

“grasping” is a common basic operation,

but it directly affects the rhythm and accuracy of the entire production line!

How to choose a gripper that precisely matches different application scenarios,

and can stably perform and operate accurately?https://heiautomation.com/

Festohttps://www.facebook.com/profile.php?id=100087291657130

The pneumatic “Jack of All Trades” is expected to be launched in the second to third quarter of 2026. From micro to heavy-duty, it precisely builds a series of gripping products that integrate rigidity, flexibility and reliability. Hold your breath and take a look at how powerful they are with their full-on presence!

Three-point air claws: HPCR.Stronglyhttps://heiautomation.com/about/ focus on both internal and external stability.HPCR adopts T-type guide rails and concentric motion structure, featuring excellent resistance to torque and process force capabilities. It is suitable for both internal and external grasping tasks and is a reliable choice in high-load scenarios.

Strong grasping range: The travel range is from 3 to 10mm. The total grasping force ranges from 303N to 10,926N.

High repeatability accuracy: ±0.03mm, ensuring consistent movements.https://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6j

Multi-environment compatibility: Supports working temperatures from -10°C to +90°C. All specifications can be used in battery production (F1a) and the food industry (H1 grease).

Strong protection performance: Standard IP40. Dust-proof derivative type can reach IP64

Perception function is complete: Supports proximity switches, position transmitters and inductive sensors integrated togetherhttps://heiautomation.com/contact-us/

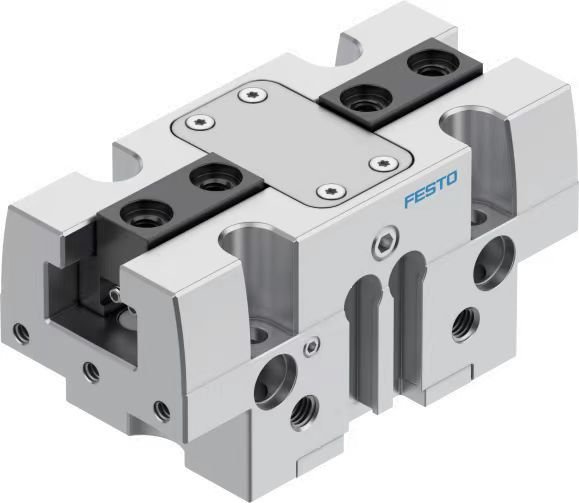

Parallel air gripper: HPPR.Flexible schedulehttps://heiautomation.com/about/ and easy installation.HPPR features parallel movement and compact structure, offering multiple specifications and derivative types, which can easily match various scenarios such as handling and assembly, general mechanical manufacturing, and machine tool manufacturing.

The travel options are diverse: the total travel ranges from 2 to 50mm, suitable for different-sized workpieces.

The gripping force is powerful: at 0.6 MPa, the gripping force range is from 50N to 6550N.

The application compatibility is high: the dust-proof type can reach IP64https://heiautomation.com/, providing functions such as normally open/normally closed and large clamping force, and the derivative types are comprehensive.

The sensor compatibility is strong: it can integrate T-shaped slot and C-shaped slot sensors to achieve precise position feedbackhttps://studio.youtube.com/channel/UC5jh-_J8N51BACPDqMnnT6Q/videos/upload?filter=%5B%5D&sort=%7B%22columnType%22%3A%22date%22%2C%22sortOrder%22%3A%22DESCENDING%22%7D.

Rotating air gripper: HPRR.Adjustable https://www.facebook.com/profile.php?id=100087291657130angle, outstanding torque.As a reliable and durable rotating pneumatic gripper, HPRR has a maximum opening angle of 180°, suitable for complex processes requiring rotational angles. It features high clamping force, spring force support, and various derivative types with different sealing components, providing a complete product range.

Flexible closing force: The range varies from 1.5 to 131 Nm depending on the specification.

Combination of rigidity and durability: The sliding bearing guide rail and embedded gripper design ensures resistance to impact, long service life, and strong environmental adaptability: Working temperature range is 5°C to 90°C. Supports various sensors: Compatible https://www.instagram.com/sunny.zeng5/with T-slot, C-slot sensors and inductive sensors.