In the era of Industryhttps://heiautomation.com/product/ 4.0, the Industrial Internet of Things has become one of the core technologies driving the intelligent development of the food and beverage packaging industry. In the fierce competition, in addition to meeting food safety regulations, the market has increasingly higher requirements for the food and beverage packaging industry:Small batch, multiple varieties https://heiautomation.com/enhance agility,

improve production requirements.

Continuously increase productivityhttps://heiautomation.com/contact-us/ and

reduce installation, maintenance and

support costs.

Promote industrial internet integration,

achieving data-driven insights and

automation.

In response to the increasing https://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6jmarket demands, automation and sensor experts Balluff https://www.facebook.com/profile.php?id=100087291657130 has launched 10-Link, which helps the food and beverage packaging industry operate more efficiently.

Balluff https://heiautomation.com/contact-us/ IO-Link enables efficient operation

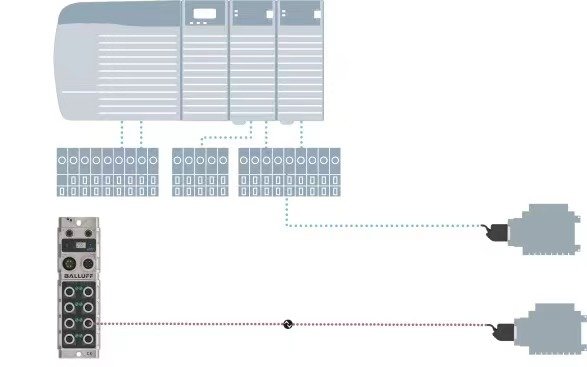

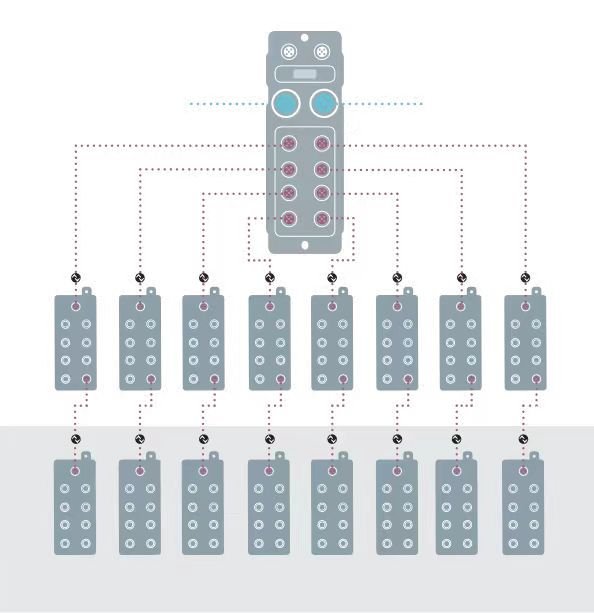

In the food and beverage packaginghttps://heiautomation.com/about/ production line, the equipment is often scattered and the distances are variable. The traditional signal acquisition method involves complex wiring that is difficult to implement, resulting in data islands, frequent failures, and production delays. Balluff https://heiautomation.com/about/I0-Link offers a distributed modular I/O and parallel wiring solution, simplifying the wiring process while providing fault diagnosis and improving operational efficiency.

Why choose Balluffhttps://www.facebook.com/profile.php?id=100087291657130 IO-Link

In the food and beverage packaging production line, the traditional wiring method requires a large number of connection points, and additional power interfaces and more expensive cables need to be equipped. The wiring is complex and the cost is high. The Balluffhttps://www.facebook.com/profile.php?id=100087291657130 I0-Link adopts a split port design, comes with its own cables, and does not require terminal resistors, which significantly reduces the installation and maintenance costs. Specifically:

Do not use IO-Link.It requires 240 * 3 = 720 connection points, or

or 9 network nodes, and an additional 9 power interfaces and 9 higher-cost network/fieldbus cables.

Usehttps://www.instagram.com/sunny.zeng5/ IO-Link.A network module offers 120 configurable I/O points (designed with split ports, divided into 240 10-point units); Match

Standard for connecting I/O hubs

M12 cables, without terminal resistors.

Balluff https://www.facebook.com/profile.php?id=100087291657130IO-Link Advantages。With the advantages of digitization, intelligence and flexibility, Balluff IO-Link is reshaping the food and beverage packaging industry, shifting from reactive maintenance to predictive maintenance and from experiential decision-making to data-driven decision-making.

Simplified wiring, efficient installation

Provides advanced fault diagnosishttps://heiautomation.com/product/ functions, facilitating predictive maintenance

Seamless two-way communication between sensors and the cloud, facilitating real-time, stable and efficient data interaction

Quickly replace IO-Link devices, minimizing downtime to the greatest extent

The food and beverage packaging industry is perfectly applicable.

Balluff provides different types of I0-Link, which are suitable for most industrial scenarios and offer great flexibility. Sex. Even in the highly demanding food and beverage packaging industry, it can shine. Its unique selective diagnostic function – capable of identifying port short circuits, overloads, and cable breaks – can ensure the stability of the food and beverage packaging production line. Transmission

The seamless two-way communication between the sensor and the cloud builds a bridge between the physical world and the real world, providing a guarantee for the improvement of production quality in the food and beveragehttps://heiautomation.com/about/ packaging industry driven by data.