The profibusDP master-to-PROFINET https://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6jgateway plays a crucial bridging role in the field of industrial automation. It enables devices with different communication protocols to connect and communicate with each other, thereby achieving data exchange and the transmission of control instructions. Especially when communicating the E+H flowmeter with the 1200plc, the application of this conversion gateway is particularly important.

profibusDP is a fieldbus standard widely used in the field of industrial automation, which adopts a master-slave communication mode. In this structure, the master station is responsible for controlling and managing the entire network, while the slave stations perform corresponding operations according to the instructions of the master station. However, with the development of industrial automation technology, Ethernet technology has gradually emerged. Its high-speed and stable transmission characteristics have led to an increasing number of devices beginning to support Ethernet interfaces. This leads to a question: How can the traditional profibusDP master station communicate effectively with the new profinethttps://heiautomation.com/product/ devices

To solve this problem, the Xingda Yikong profibusDP master Station to profinet Gateway (XD-PNPBM20) was born. The main function of this gateway is to achieve the conversion between two different communication protocols, enabling the profibusDP master station to seamlessly integrate with profinet devices. Through this transformation, devices that originally could only communicate on the profibusDP https://heiautomation.com/about/network can now be extended to the Ethernet environment, thereby significantly enhancing the flexibility and scalability of the system.

In practical applications, we need to connect the E+H flowmeter to the profibusDP master station to the profinet gateway. The E+H flowmeter, as a high-precision flow measurement instrument, is widely used in various industrial Settings. It can communicate with the outside world in multiple ways, including the two common industrial communication protocols, profibusDP and profinet. After we select the profibusDP master station to profinet gateway, the data of the E+H flowmeter can be forwarded to the 1200plc through this gateway.

The 1200plc is a high-performance programmable logic controller launched by Siemens, which is widely used in various automatic control systems. It has powerful processing capabilities and rich input and output interfaces, and can meet complex industrial control requirements.

Next, the communication configuration will be carried out based on the GSD file of the E+H flowmeter

Set the dp slave station address

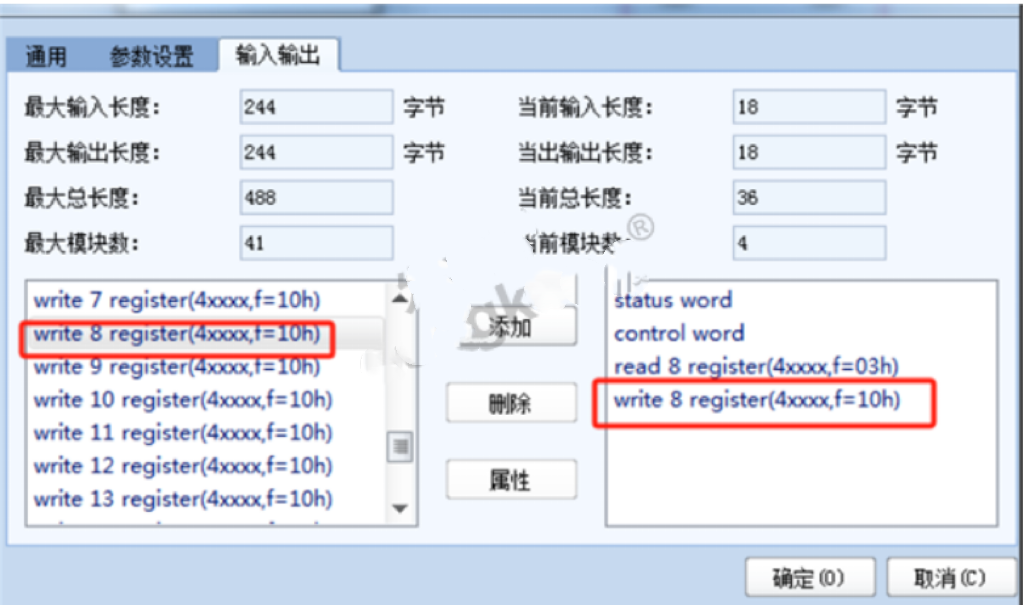

Add read/write instructions

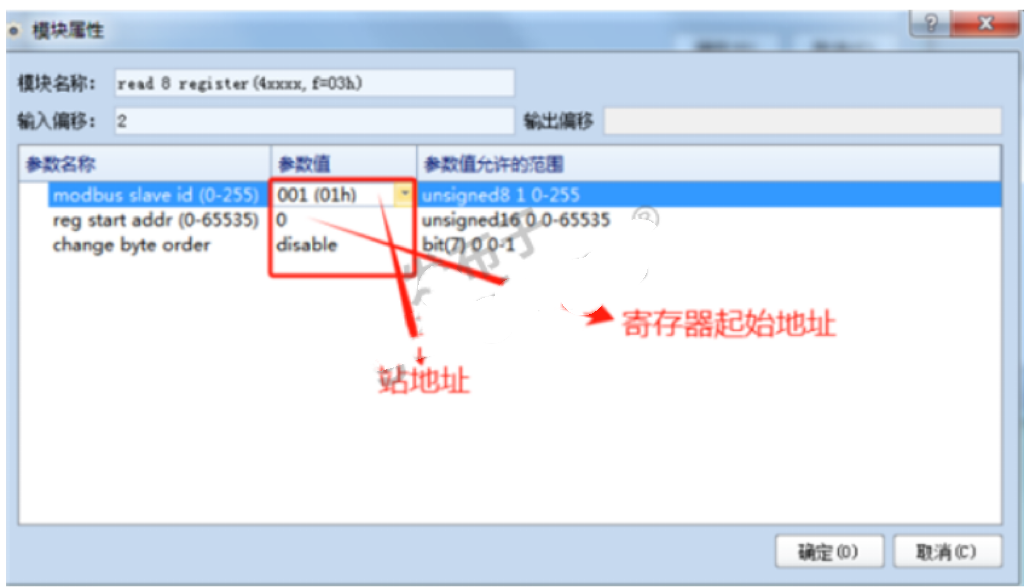

Configure instruction parameters

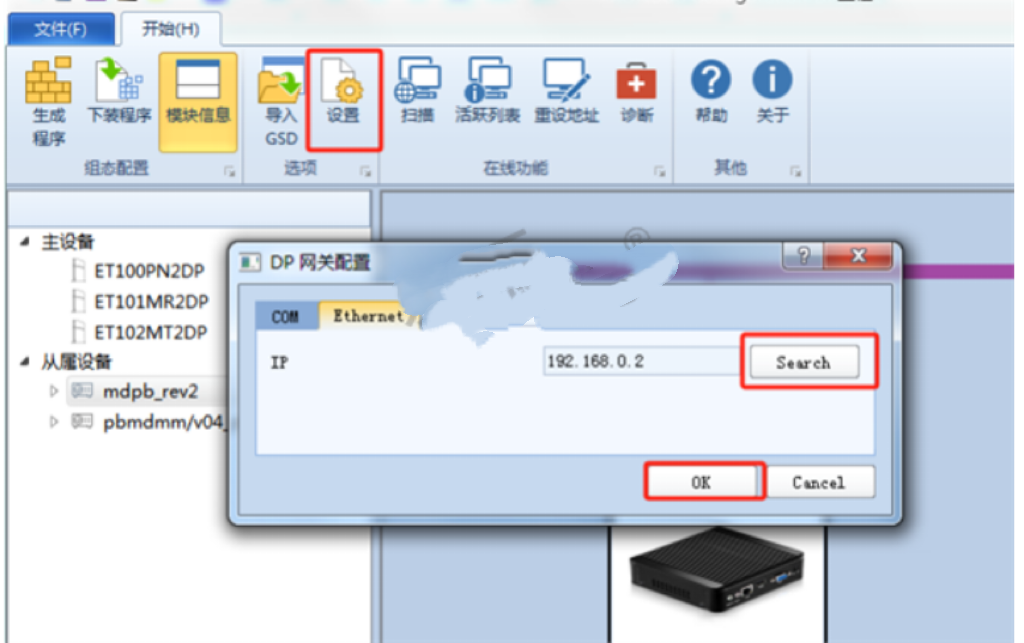

Click “Settings” to search for gateway devices

Finally, by downloading the program, the configuration of converting the profibusDP master station to the profinet gateway is completed

The communication between the profibusDP master station, profinet gateway, E+H flowmeter and 1200plc is a typical and practical application scenario in the field of industrial automation. It not only solves the interoperability problem among devices with different communication protocols, but also can improve the overall performance and reliability of the system. In the future development, with the continuous advancement of industrial automation technology, it is believed that the application of this conversion gateway will become increasingly widespread, bringing more convenience and benefits to industrial production.