In the current bottled beverage industryhttps://heiautomation.com/product/, particularly in the fields of food, beverages, and pharmaceuticals, the requirements for the sterility and quality of product packaging have reached an unprecedented level. The application of the rotating blow molding machine for sterile packaging serves as a crucial equipment to ensure the quality of the bottles. The performance of this equipment directly affects the safety and production efficiency of the products. Among this important equipment, the IMI Norgren blow molding valve assembly, with its outstanding innovative applications, has become a leader in this field, providing advanced solutions for numerous enterprises.

1、Integrated design:The IMI Norgrenhttps://heiautomation.com/about/ blow molding valve assembly adopts an integrated design concept, integrating precise gas control technology and optimized structural design to meet the new innovative demands of the market. It integrates pre-blowing, mid-blowing, forming blow, and exhaust functions, reducing the connection of external pipelines and the complex wiring of the control system. The IMI Norgren AVSP-R-4V four-valve blow molding valve assembly can be used in the new generation of sterile blow molding machines, meeting the operational requirements of customers in terms of energy efficiency, maximum capacity, and sterile applications. The new four-valve blow molding valve assembly operates at a speed of 3,000 BPH, which is 20% higher than that of competitors.

2、high precision control:The IMI Norgrenhttps://heiautomation.com/ bottle blowing valve assembly employs an advanced control system, which can precisely control the pressure and flow of the gas. During the bottle blowing process, the pressure and flow of the gas directly determine whether the bottle blank can expand uniformly, thereby affecting the uniformity of the bottle wall thickness and the overall quality. Taking the six-valve group six-step bottle blowing process as an example, we can achieve a pressure control accuracy within an extremely small error range, ensuring that every bottle produced has a highly consistent quality standard, effectively reducing the defective rate. This process not only increases the recovery rate of compressedhttps://heiautomation.com/contact-us/ gas to over 40%, but also enables the single-chamber production capacity of the equipment to reach a bottle blowing speed of 3,000 bottles per hour, reducing production costs for customers and enhancing market competitiveness.

3、Compatibility with a sterile https://heiautomation.com/about/environment:To meet the specific environmental requirements of the aseptic application of rotary bottle blowing machines, the IMI Norgren bottle blowing valve assembly has been meticulously optimized in terms of material selection and surface treatment. The valve body and internal components are made of materials that comply with FDA food safety certification. These materials have excellent biocompatibility and do not release harmful substances that could contaminate the bottle blanks and the production environment. At the same time, the surface of the bottle blowing valve is specially treated to achieve an extremely low roughness, making it difficult for microorganisms to grow and facilitatinghttps://heiautomation.com/about/ cleaning and disinfection. Thus, we can ensure the aseptic state throughout the entire process from sterilization of the bottle blanks to bottle blowing, filling, and cap sealing.

The innovative application of IMI Norgrenhttps://heiautomation.com/contact-us/ blow valve assembly in the aseptic rotating blow molding machine brings new opportunities to the bottle packaging industry. It demonstrates significant advantages in terms of ensuring product quality, improving production efficiency, and reducing operating costs. If you are looking for more advanced and efficient blow molding technology, please contact IMI Norgrenhttps://www.facebook.com/profile.php?id=100087291657130 immediately to let innovation lead your production transformation.

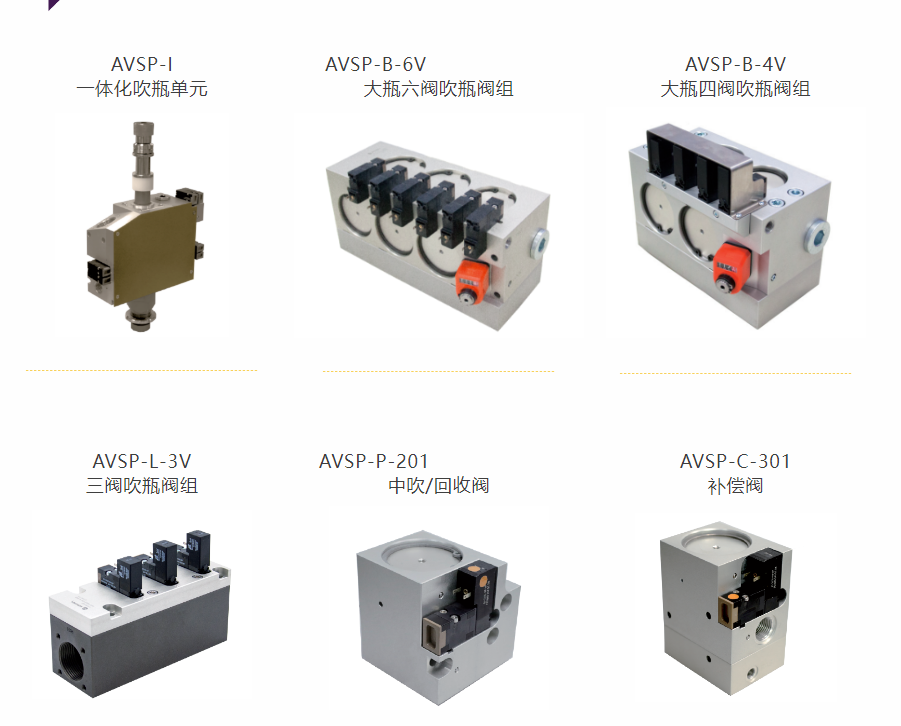

More IMI Nobel PET Bottle Blowing Industry Product Collections