Pneumatic Industry Equipment and Accessories: A Comprehensive GuideIntroductionhttps://heiautomation.com/product/

The pneumatic industry is a cornerstone of automation and industrial processes, leveraging compressed alr orother gases to power machinery and equipment, Pneumatic systems offer numerous advantages, includinghigh speed, precision, cleanliness, and cost-effectiveness. This guide delves into the equipment andaccessories that form the backbone of the pneumatic industry, highlighting their functionalities, applicationsand technical specifications.https://heiautomation.com/

Key Pneumatic Components

- Air Compressors:Overview: Air compressors are the heart of any pneumatic system, converting mechanical energy intocompressed air. They are available in various types, including reciprocating, rotary screw, andhttps://heiautomation.com/about/ centrifugacompressors,each suited for different applications and flow rates.

Types:

Reciprocating Compressors: Use pistons moving in cylinders to compress alr. Suitable for low to mediumflowhttps://heiautomation.com/about/ rates and high pressures.

Rotary Screw Compressors: Utilize two meshing helical screws to compress air Efficient for continyousoperation and medium to high flow rates.

Centrifugal Compressors: Use high-speed rotating impellers to compress air, ldeal for large flow rates atrelatively low pressures.

Applications:

Powering pneumatic tools and machinerySupplying compressed air for industrial processesGenerating https://heiautomation.com/product-category/danfoss/breathable air in medical facilities

Accessories:

Air Dryers: Remove moisture from compressed air to prevent corrosion and maintain system efficiencyFilters: Remove particulate contamination from air to protect equipment and ensure cleanliness.Lubricators: Provide lubrication to pneumatic tools and components, reducing wear and tear.

2.Pneumatic Cylinders

Overview: Pneumatic cylinders convert compressed air into linear motion, driving a wide range of industrlaapplications. They come in various configurations, including single-acting, double-acting, and rodlesscylinders.

Types:

Single-Acting Cylinders: Operate in one direction, using compressed air to extend the piston and springsor gravity to return it.Double-Acting Cylinders: Use compressed air to both extend and retract the piston, offering greatercontrol and force.

Rodless Cylinders: Feature a sliding carriage instead of a piston rod, providing a more compact design andincreased stroke length.

Applications:

Automating assembly lines

Operating clamping and gripping mechanismsPositioninghttps://heiautomation.com/product/ and moving loads

Accessories:

Position Sensors: Detect cylinder position and stroke length, ensuring precise control and feedback.** Cushions**: Absorb impact at the end of the stroke, reducing noise and wear.Magnetic Switches: Trigger electrical signals based on cylinder position, enabling automation and controlintegration.

3.Pneumatic Valves

Overview: Pneumatic valves control the flow of compressed air in pneumatic systems, directing it to variouscomponentshttps://heiautomation.com/about/ and tools. They are crucial for system efficiency, safety, and reliability.

Types:

Directional Control Valves: Regulate air flow to cylinders and other actuators, controlling their operation.

Available in 2-way, 3-way, 4-way, and 5-way configurations.

Pressure Control Valves: Regulate system pressure, protecting equipment from over-pressurization and

ensuring consistent performance.

Flow Control Valves: Throttle air flow to control cylinder speed and force, enabling precise motion control.

Applications:

Controlling the operation of pneumatic tools and machineryRegulating system pressure and flow ratesEnsuring safety and reliability in automated processes

Accessories:

Valve Mlanifolds: Combine multiple valves into a single unit, simplifying installation and maintenanceSolenoids: Electrically operated devices that actuate valves, enabling remote control and automation.Position Indicators: Visually indicate valve position, aiding in troubleshooting and system monitoring

4.Pneumatic Fittings and Tubing

Overview: Pneumatic fittings and tubing connect components within pneumatic systems, ensuring theefficient and reliable transfer of compressed air. They come in a variety of materials, sizes, and configurations

to suit different applications.

Types:

Tubing: Available in materials such as nylon, polyurethane, and PVC, offering varying degrees of flexibilitychemical resistance, and temperature tolerance.

Fittings: Include connectors, elbows, tees, and unions, enabling the assembly of complex pneymaticcircuits.

Applications:

Connecting air compressors to pneumatic tools and equipmentRouting air lines within machinery and equipmentFacilitating maintenance and repairs

Accessories:

Tube Clamps: Secure tubing to brackets and other supports, preventing movement and leaksQuick Disconnects: Allow easy connection and disconnection of tubing, enabling rapid tool changes andsystem reconfiguration.

Fitting Protectors: Shield fittings from damage, extending their lifespan and reducing downtime.

5.Pneumatic Pressure Regulators

Overview: Pneumatic pressure requlators control the pressure of compressed air within pneumatic systemsensuring consistent performance and protecting equipment from damage. They are essential for maintainincsystem efficiency and reliability.

Types:

Single-Stage Regulators: Reduce inlet pressure to a desired outlet pressure, suitable for most industrial

applications.Two-Stage Regulators: Offer finer pressure control and better stability, ideal for sensitive applicationsrequiring precise pressure regulation.

Filter-Regulators: Combine pressure regulation with particulate filtration, ensuring clean and controlled airsupply.

Applications:

Protecting pneumatic components from over-pressurizationMaintaining consistent pressure in automated processesEnsuring safe and reliable system operation

Accessories:

Gauges: lndicate inlet and outlet pressures, aiding in system monitoring and troubleshootingDrain Valves: Automatically remove condensate from the regulator, preventing water accumulation andcorrosion.

Pressure Relief Valves: Open to release excess pressure, preventing system overpressure and potentialdamage.

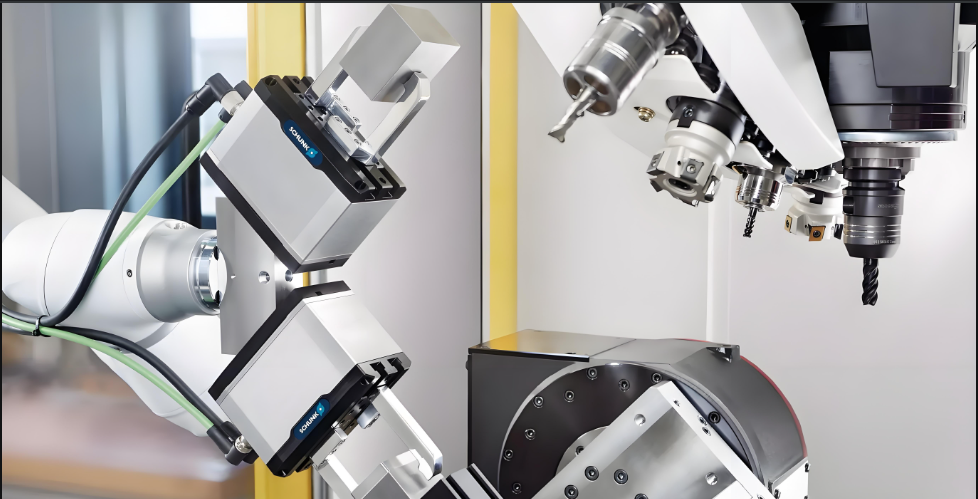

6.Pneumatic Actuators

Overview: Pneumatic actuators convert compressed air into mechanical motion, driving a wide range ofindustrial applications. They come in various forms, including rotary actuators, grippers, and linear slides

Types:

Rotary Actuators: Use compressed air to rotate a shaft or output member, ideal for valve operation,

positioning, and other rotational tasks.Grippers: Utilize pneumatic cylinders to open and close jaws or fingers, gripping and releasing objects inautomated processes.

Linear Slides: Combine pneumatic cylinders with guiding mechanisms, providing precise linear motion withhigh rigidity and accuracy.

Applications:

Automating assembly and packaging processes

Handling and manipulating materials

Positioning and aligning components

Accessories:

Position Feedback Devices: Provide electronic signals indicating actuator position, enabling precise controland monitoring.

Mounting Brackets: Secure actuators to machinery and equipment, ensuring stable and reliable operation.Sensors: Detect the presence, position, or orientation of gripped objects, enhancing system functionalityand safety.