Filling is the process of precisely and quantitatively injecting the medium into packaging containers (such as bottles and cans). It is closely related to our lives. From the https://heiautomation.com/product/milk in the morning, the juice at lunch to the soy sauce in the kitchen and the body wash for washing up, none of them can do without bottling. To ensure that the capacity of each bottle is precisely consistent, the filling equipment relies on high-precision metering devices (such as flow meters, piston cylinders) and intelligent filling valve “control systems” to complete https://heiautomation.com/quantitative filling in an extremely short time. Through real-time monitoring by sensors, it guarantees that the weight of each product received by consumers is accurate and reliable.

Driven by both Industry 4.0 and lean production, filling and quantitative processes are confronted with higher challenges: precision fluctuations in short-cycle filling, insufficient flexibility in multi-variety production, the need for data traceability under strict regulations, as well as the continuous pressure to optimize energy consumption and costs. The new generation of filling electromagnetic flowmeters Dosimag https://heiautomation.com/about/D5AB and filling mass flowmeters “DosimassD8AB” from Endeshauser respond to industry pain points with technological innovation – precision, intelligence and reliability.

Core technology upgrade: Comprehensive improvement in precision and efficiency

High-precision sensors and structural optimization

Filling electromagnetic flowmeter Dosimag https://heiautomation.com/contact-us/D5AB

Fully welded housing: Better protection against moisture invasion, reduced energy consumption, higher reliability and robustness

Support for temperature measurement: Real-time monitoring of the temperature of the filling medium, which can be synchronously uploaded to the monitoring system to continuously monitor the filling process. High repeatability: Provide reliable measurement results, reduce errors and uncertainties, and ensure product quality and production efficiency. PVDFQ process connection: To meet the filling requirements of corrosive media, add PVDFhttps://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6j standard process connection to ensure filling safety.Compact design: Lighter in weight and thinner in size, suitable for the filling requirements of large rapid filling machines.

Filling mass flowmeter Dosimass D8AB

High repeatability: When the filling time is greater than 1.5 seconds, the repeatability of mass flow rate o is ≤0.1%

Dynamic Drip Compensation (DLC) algorithm for optimizing the control of filling endpoints under pressure fluctuations

It features rapid filling of extremely small amounts of media (DN01) and rapid filling of buckets, boxes and bags (DN40).

Standard 0.15% high-precision output enhttps://heiautomation.com/contact-us/sures accurate filling down to every drop

The surface roughness Ra of the liquid contact surface is less than 0.38 um, meeting the requirements of aseptic filling.

- Multiple signal input and output modes

The pulse/frequency/switch output Q is compatible with traditional PLC systems and supports high-speed counting modules

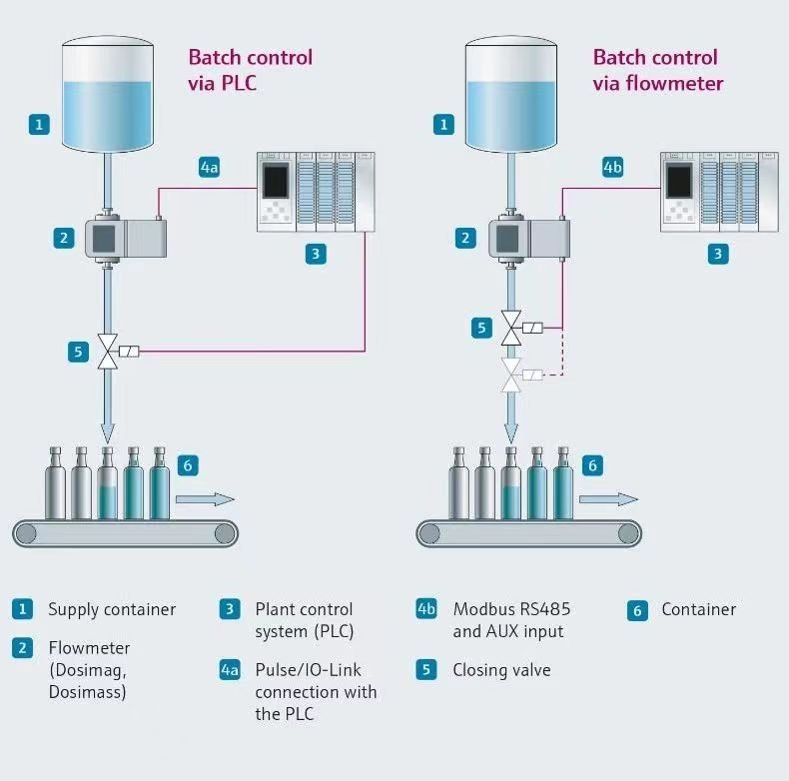

Modbus RTU batch processing mode: Built-in filling logic controller, reducing the complexity of PLC programming and saving the cost of high-speed pulse counting cards

Pulse &l0-Link dual-mode output: It combines the traditional pulse and l0-Link digital communication dual modes, seamlessly achieving digital upgrades and reducinghttps://heiautomation.com/about/ future upgrade costs

Integrated batch processing Function: Through the integrated batch processing function, the flowmeter can directly manage the filling process, and the filling flowmeter directly controls the filling valve, shortening the system control response time and improving the overall filling efficiency.

lO-Link Communication: Leading the digitalizationhttps://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6j/shorts of filling, Intelligently leading the future

The acceptance and usage rate of l0-Link in the field of factory automation are constantly increasing. Simple and easy to use, it enables continuous access to process data. IO-Link upgrades the one-way pulse signal of the traditional filling instrument to two-way digital communication, achieving full-link interaction in parameter configuration, process data collection, and diagnostic information.

As the first filling dedicated flowmeter supporting lO-Link, D5AB/D8AB promotes the intelligence of the production line through the following functions:

Seamlessly integrate the existing system, with dual outputs of pulse and 10-link: Retain the traditional pulse signal while transmitting process data through 0-link, and be compatible with both new and old control frames

Pulse (fast output) is used to manage the rapid filling process. It can be easily debugged through lO-Link, parameters can be remotely configured and backed up, and parameters can behttps://heiautomation.com/contact-us/ automatically downloaded when changing equipment to reduce downtime

Real-time reading of multiple parameters such as flow rate, density and temperature, supporting process optimization and predictive maintenance

To prepare for the digitalization of factory equipment, the design of the new filling equipment can be fully integrated with lO-Link to give full play to the advantages of digitalization.

Sanitary design and industry compliance:Meet global industry hygiene design standards and ensure the safety and reliability of the production process.

· Food and Beverage https://www.facebook.com/profile.php?id=100087291657130industry: Complies with the requirements of EHEDG, 3A, FDA, Declaration of Food Contact Materials (EU/CN/US)GB 4806

Life Sciences: Compliant with cGMP requirements

It meets the filling requirements in explosion-proof environments and can be filled safely, stably and in compliance with regulations in such environments

The precision and intelligence of the filling process are not only the competitive focus of production efficiency but also the cornerstone of quality compliance. The new generation of filling electromagnetic flowmeter Dosimag D5AB and filling mass flowmeter Dosimass D8AB of Endeshaushttps://studio.youtube.com/video/d-1jAFjjPHU/edit, through the innovation of sensing technology, l0-Link digital technology and adaptive control algorithm, not only solve the common industry problems such as accuracy attenuation and fluctuation of medium characteristics in short-cycle filling, It also provides a progressive digital upgrade path for the production line with modular design