In industrial automated production, sensors are like the “eyes” of the equipment, responsible for detecting the presence, position and color of the items. However, in some special situations, such as in the presence of strong electromagnetichttps://heiautomation.com/ interference, in spaces that are narrow, or when it is necessary to detect tiny objects, ordinary sensors often fall short. This

At that time, you will need a more professional “inspection expert” – an optical fiber sensor.

What is an optical fiber sensor?

In simple terms, it consists of two main parts:

Optical fiber: A very thin glass or plastic fiber with a lens at the end, responsible for transmitting https://heiautomation.com/product/and receiving light. It is small in size and made of special materials.

Amplifier: An independent control unit used to process optical signals, issue switch instructions, and provide status indication and sensitivity adjustment functions.

The two are connected through optical fibers, separating the “light-emitting” and “light-receiving” parts. This unique structure brings unparalleled advantages.https://www.facebook.com/profile.php?id=100087291657130

For market applications, Labiotech has officially launched three new series of optical fiber sensors, each equipped with unique features to meet the diverse needs of customers.LV 453B.LV 443B.XR.LV 443B

Optical fiber amplifier sensorhttps://www.facebook.com/profile.php?id=100087291657130

What practical problems can it solve for you?

1、High anti-interference ability, more stable operation

Challenges: In the vicinity of frequency converters and large motors, ordinary sensorshttps://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6j

are prone to electromagnetic interference, resulting in incorrect actions and production pauses.

Solution: Fiber optic sensors use optical signals for detection, which are completely unaffected by electromagnetic interference. Even in the most complex electrical environments, they can ensure the stability and reliability of detection, allowing your production line to run smoothly continuously.

2、The sensor head is small and durable, with strong adaptability.https://heiautomation.com/contact-us/

Challenges: Limited installation space, or high temperature, dust, corrosive chemicals in the environment.

Ordinary sensors are large in size and prone to damage.

Solution: Fiber optic head. It is very small and can be easily installed into extremely narrow spaces. At the same time, the special stainless steel shell and glass fiber have advantages such as high temperature resistance, corrosion resistance, impact resistance, and longer lifespan, which can adapt to various harsh industrial environments.

3、High detection accuracy, capable of seeing tiny objectshttps://heiautomation.com/about/

Challenges: Need to detect tiny electronic components, transparent glass bottles, small gaps, or distinguish subtle color differences.

Ordinary sensors cannot accurately identify them.

Solution: We offer various different models of optical fiber heads,

which can achieve extremely high detection accuracy. Whether it’s tiny chip pins or transparent objects, they can be accurately and quickly identified, meeting the needs of precision manufacturing.

What other features does the products of Leuze Measurement have?https://studio.youtube.com/channel/UC5jh-_J8N51BACPDqMnnT6Q/videos/short?filter=%5B%5D&sort=%7B%22columnType%22%3A%22date%22%2C%22sortOrder%22%3A%22DESCENDING%22%7D

Simple setup: The buttons on the amplifier and the digital display “show” make adjusting the sensitivity extremely simple. One-click setting, easy to operate.

Fast response: Millisecond-level response time, perfectly matching high-speed production lines.

Multiple models available: We offer reflective type and diffuse type fiber optic sensors at different prices to meet your different application needs.

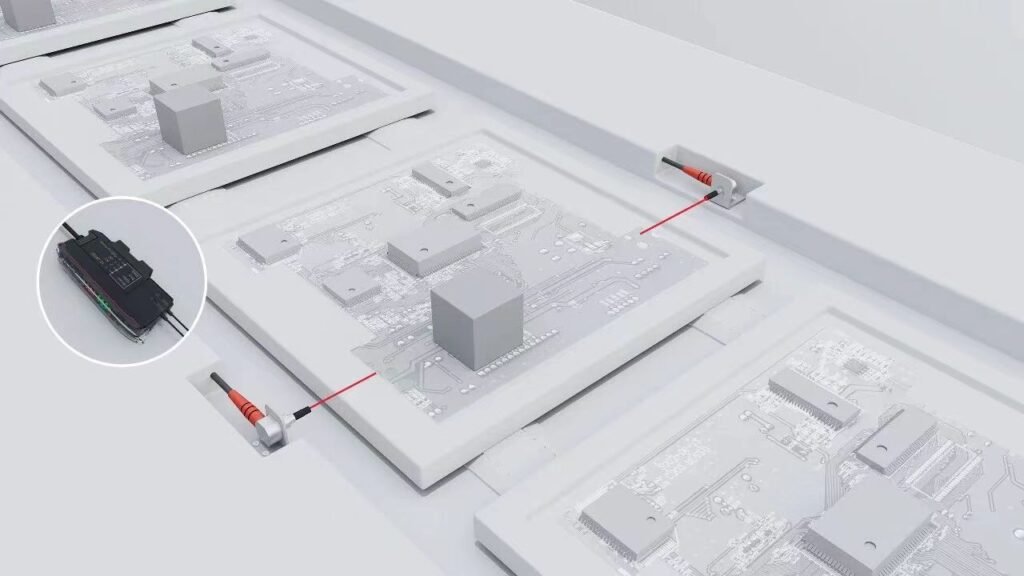

1、Electronic industry – Precise detection of PCBA boards on conveyor lineshttps://www.facebook.com/profile.php?id=100087291657130

During the SMT (Surface Mount Technology) https://heiautomation.com/product/assembly process, the PCB (Printed Circuit Board) is subjected to high-speed flow of components. The board surface is densely covered with various components of different heights, and the space is compact. Meanwhile, there are numerous frequency converters and servo motors around the production line, resulting in strong electromagnetic interference. Ordinary photoelectric sensors are prone to interference and false alarms, or they cannot be used due to space limitations, leading to the risk of the entire line stopping. The solution:

The reflective right-angle optical fiber can flexibly detect the presence of various components (such as capacitors, chips, etc.). The response time can be flexibly adjusted (40 microseconds to 16 milliseconds), adapting to the compact positioning intervals and high-speed production rhythm, significantly reducing the rate of missed detections and false detections.https://heiautomation.com/about/

2、The in vitro diagnostics (IVD) industry – When the mechanical hand grabs, it can reliably detect whether there is a test tube.

In fully automated chemiluminescence immunoassay https://heiautomation.com/product/analyzers, such as IVD devices, the robotic arm needs to pick up the sampling tubes from the tube rack. Once it misses one, it not only wastes time but also may cause the sample sequence to be disordered, resulting in serious medical errors. Therefore, a sensor that can 100% reliably detect the presence of transparent or semi-transparent tubes without false positives or negatives, and does not contaminate the samples is needed.

Solution:

We offer a fiber optic sensor specifically optimized for transparent objects. Through special functional design, it can sensitively capture the subtle contrasts of transparent glass bottles, achieving stable and error-free detection. The differential mode of the sensor “can intelligently filter instantaneous jitter signals (which can be set for pulse duration), effectively detecting erroneous signals caused by misalignment or jitter. The millisecond response speed is perfectly synchronized with the high-speed robotic arm.

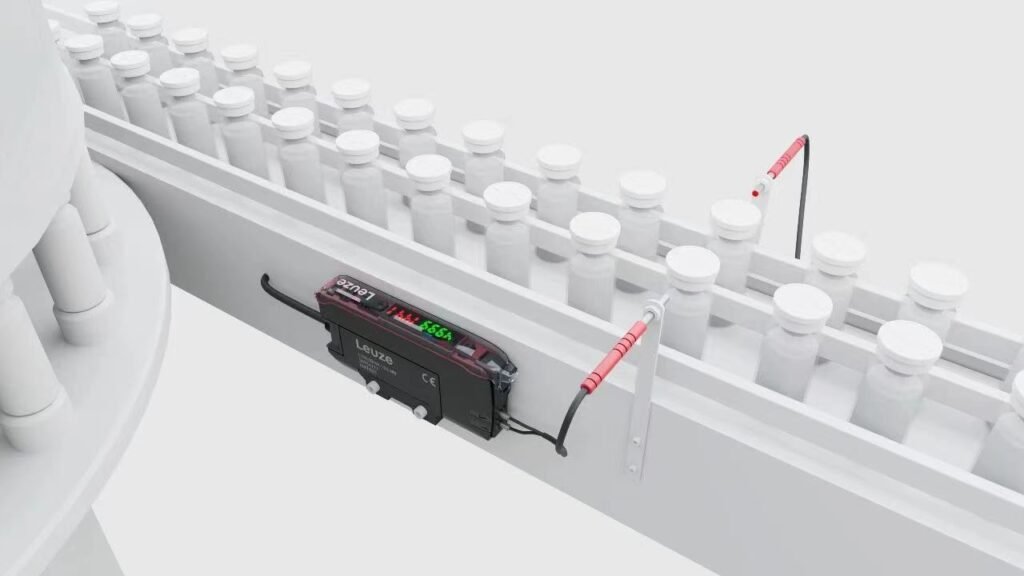

3、Pharmaceutical industry – Identifying transparent vials on the conveying line

On the production line of syringes, it is necessary to detect the presence and positionhttps://heiautomation.com/product/ of the transparent glass syringes to control the processes of filling, sealing, conveying and packaging.

Solution:

The LEUZE optical sensor has the ACC mode. The sensor can automatically adjust the intensity of the emitted light according to the external environment to meet the requirements of different application environments. While maintaining high throughput, it minimizes the maintenance requirements caused by water vapor or dust. It is teachable and simple with only two-point teaching operations, which can be quickly set up without any threshold. The response time is ultra-short (40 microseconds), and it can detect a 1mm gap at a conveying belt speed of 25 metershttps://www.facebook.com/profile.php?id=100087291657130 per second (theoretical value), maintaining high throughput to the greatest extent.

If you are struggling with complex detection conditions and are also seeking for more stable, precise and reliable production efficiency, our optical fiber sensors will be your best choice.