The continuous improvement of quality requirementshttps://heiautomation.com/product/ for industrial and cultural paper in the papermaking industry has led to increasingly strict quality standards for papermaking wire, a key consumable. At the same time, the homogenization of competition in the papermaking wire market has intensified, with fierce competition among domestic and foreign brands and frequent price fluctuations. This has made it necessary for papermaking wire production equipment – papermaking wire weaving machines – to meet two core demands: maximizing the equipment’s full life cycle and effectively controlling maintenance costs. To this end, Bosch Rexrothhttps://heiautomation.com/ has launched an exclusive upgrade solution with excellent cost performance.

As an all-round expert in the field of automation, the products of Bosch Rexrothhttps://heiautomation.com/contact-us/ are widely used in the paper web and textile machinery industry, and have a high market share. We

Not only can it provide a complete automated new equipment system, but it can also tailor an electrical technical renovation system solution covering the entire life cycle for old equipment, meeting the diverse needs of users.

At present, the equipmenthttps://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6j of major domestic papermaking net manufacturers mainly relies on imports from Europe. The three largest global papermaking net equipment suppliers – TEXO, Jaeger and Juergens – all adopt the Bosch Rexroth servo system as the core actuation and control unit.

Nowadays, the electrical control system of the paper-making net machines imported in the 1990s is approaching the end of its lifecycle, while the mechanical performance of some complete machines is still excellent. Users have an increasing urgent need to extend the lifespan of the expensive imported equipment. Therefore, we have been constantly thinking: How can we help users understand the latest development direction of the net machine control system? How to

Enable users to gain a clear understanding of the latest servo control execution system? How to enhance the entire lifecycle of user equipment?

With its profound after-sales service experience and industry accumulation, the Bosch Rexrothhttps://heiautomation.com/ Automation Factory Service Department not only provides you with professional technical guidance, but also has developed exclusive solutions specifically for the problems users encounter in extending the equipment’s lifecycle:

Option 1: For the eliminated Rexrothhttps://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6j servo system, implement a seamless upgrade of the drive control system while retaining the original servo drive and motor. Option 2: For the eliminated original machine PLC control system, provide a seamless system upgrade service for the weaving machine equipment.

Upgrade Case

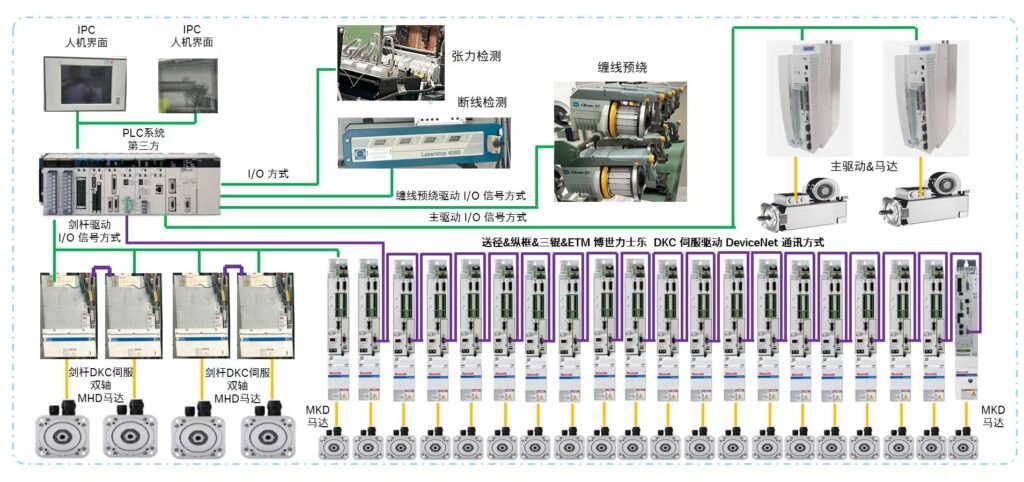

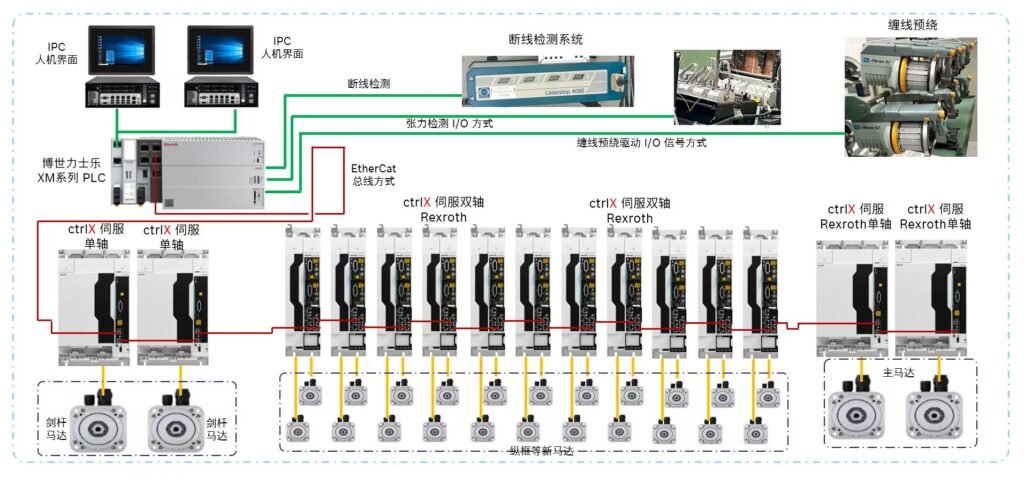

Take a recent renovation project as an example. The following topology diagram “clearly

shows the changes before and after the upgrade: The new Rexroth https://heiautomation.com/about/high-performance PLC controller XM system was adopted to replace the discontinued PLC system of a certain brand. Its programming language is flexible and uses the popular Codesys programming language environment. The discontinued Eco-Drive driver and MKD motor were replaced with our latest ctrlX Drive driver and MS2N motor.

Original system configuration

Upgraded configuration

Transformation benefits

This upgrade plan ensures a seamless migration from the old system to the new Bosch Rexroth https://heiautomation.com/system. Users can quickly adapt to the new system with their existing experience. This not only effectively reduces downtime and improves the overall efficiency of the equipment, but also achieves the goal of extending the equipment’s lifecycle at a highly cost-effective manner.

The electrical system upgrade of the user’s equipment is compatible with the new Bosch Rexrothhttps://www.facebook.com/profile.php?id=100087291657130 system.

After the upgrade, the equipment can continue to operate for more than 20 years, and the renovation cost is much lower than the investment in new equipment.

There is no need to change the operation procedures of the operators.

New training is required.