From the quality control of the early-stage processeshttps://heiautomation.com/ to the strict tests of aseptic filling, the automation equipment plays the leading role: not only do they need to “withstand shocks”, but also “be easy to clean without any dead corners”. Festo, with its innovative products and automation solutions, injects new quality productivity into the flexible production, efficiency improvement, quality traceability and sustainable development of the beverage https://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6j/shortsindustry.

Pre-processing stage.Break https://www.facebook.com/profile.php?id=100087291657130through through innovation, move steadily and achieve great progress in quality.

As the core hub connecting raw material reception and subsequenthttps://heiautomation.com/about/ processing, pre-treatment is the fundamental step in quality control, directly influencing the color, flavor and stability of the finished product.

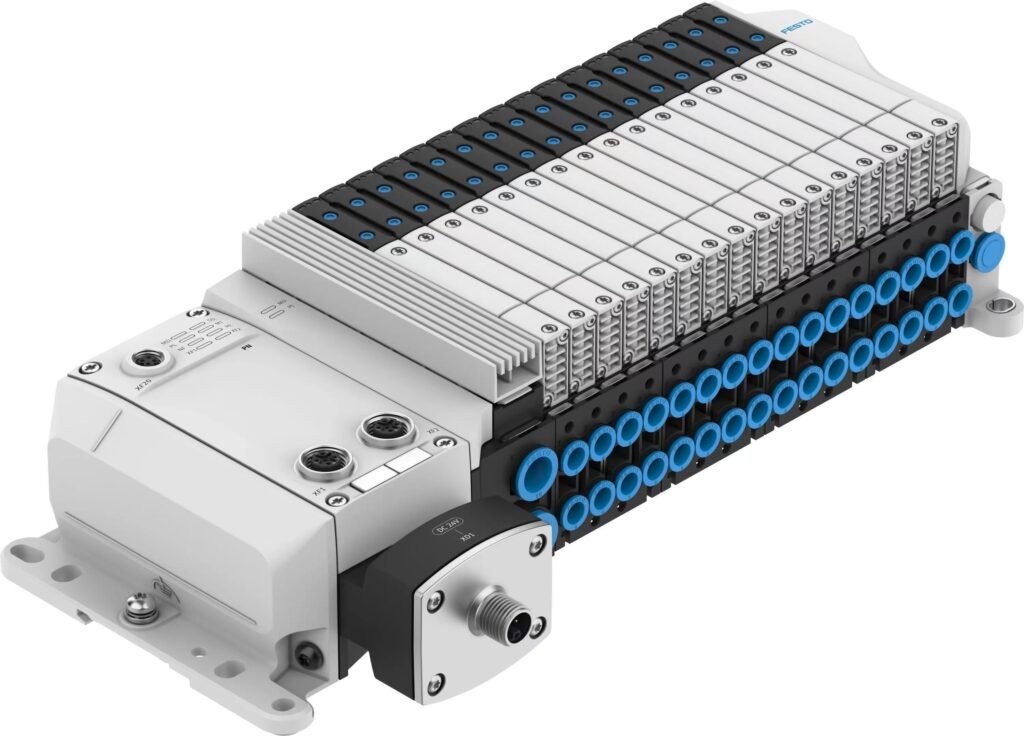

Festo adopts the latest generation VTUXhttps://heiautomation.com/ valve island, CPPB drive head controller and customized cabinet to provide a safe and efficient modular process control solution.

The design is made of fully stainless steel for hygiene purposes. The surface has no dead corners and is resistant to corrosive cleaning and high-temperature high-pressure impacts.

It is certified for explosion prevention and is suitable for scenarios with risks of flammablehttps://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6j and explosive substances such as alcoholic beverages.

It has a digital interface that seamlessly connects to the CIP system, enabling automated cleaning and data traceability, effectively improving efficiency and reducing water and chemical consumption.

Filling process.technical improvement,”Enlightenment leads to peace of mind”

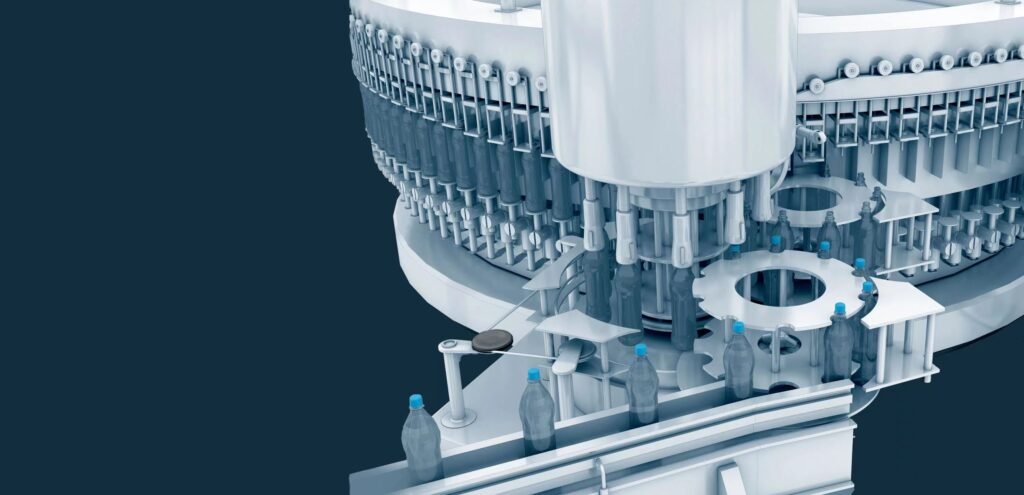

When the choice of beverages shifts from “refreshing and quenching thirst” to “healthy and reassuring”,

a “filling revolution” centered around precision, speed, hygienehttps://heiautomation.com/contact-us/ and aseptic conditions emerges quietly.

Festo has launched the IP69Khttps://studio.youtube.com/channel/UC5jh-_J8N51BACPDqMnnT6Q/videos/short?filter=%5B%5D&sort=%7B%22columnType%22%3A%22date%22%2C%22sortOrder%22%3A%22DESCENDING%22%7D high-protective stainless steel electric cylinder motion control solution (EPRF electric cylinder ” + EMMH servo motor) and a full range of sanitary components (including air pipe connectors, valve islands, cylinders, etc.)

The fully sealed structure enables direct water gun flushing, and the food-grade lubrication meets the cleanliness standards.

Digital control achieves high-precision flow stability for filling, reducing product loss and air resource https://www.facebook.com/profile.php?id=100087291657130waste, and minimizing downtime caused by component failures.

secondary packaging.Intelligenthttps://www.facebook.com/profile.php?id=100087291657130 upgrade,”Pack” encompasses everything.

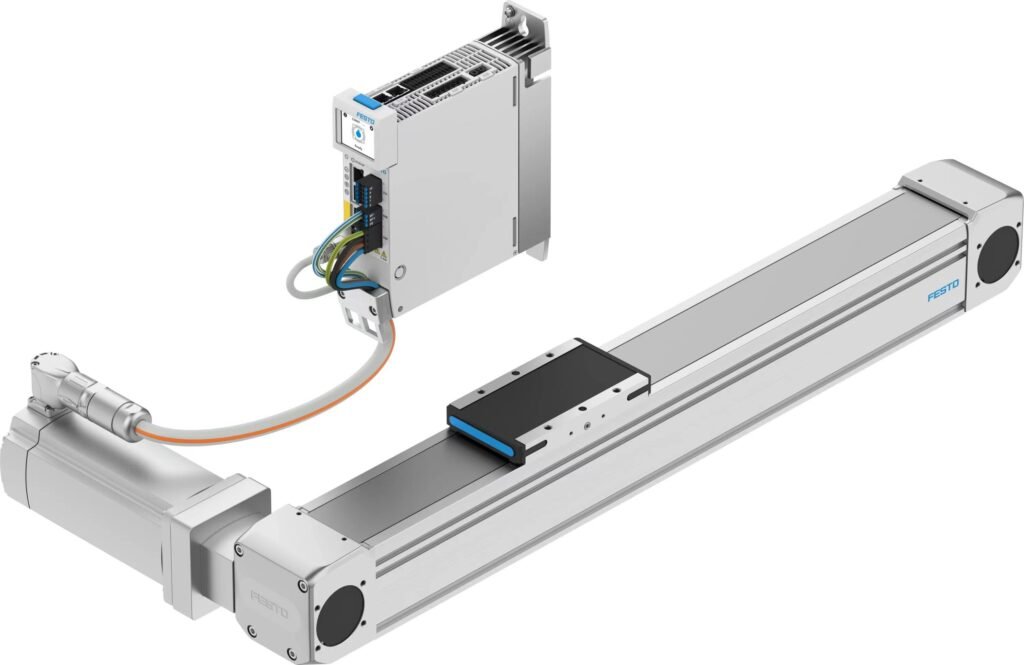

As the final packaging process, it faces challenges of labor-intensive operations and low logistics efficiency. The Festo ELGD cylinder, combined with the CMMT+EMMT dual-T electric drive unit and flexible gripper assembly, offers an efficient and flexible automated solution.

Energy management and the Festo AX predictive https://heiautomation.com/product/maintenance system continuously monitor the operating parameters of cylinders and valve islands. Through AI algorithms, it predicts potential faults and issues alerts, transforming the maintenance mode from “passive response” to “active planning”. This avoids sudden shutdowns that interrupt production, ensures logistics efficiency, reduces spare parts waste and unexpectedhttps://www.instagram.com/sunny.zeng5/ damage.