Application Challenges

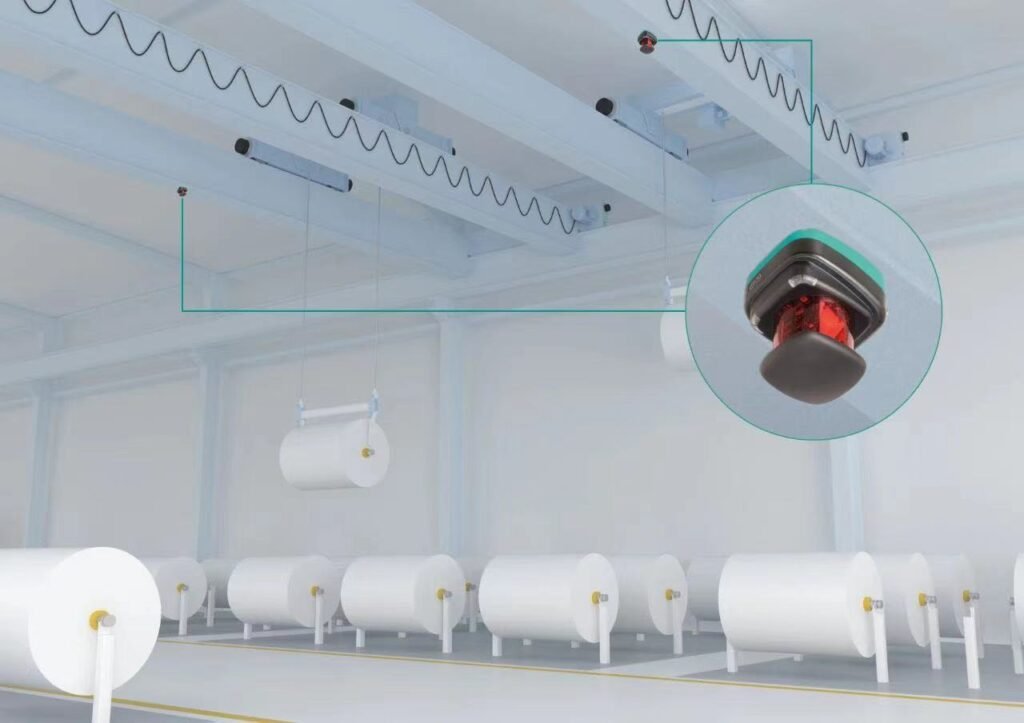

With the in-depth implementation of the national policy for upgrading intelligent manufacturing, the equipment has been upgraded to a new type, covering key functions such as remote monitoring, automated operation, fault prediction, and obstacle monitoring. Among the safety protection systems of the equipment, obstacle monitoring is particularly important. It needs to continuously and stably monitor the surrounding environment throughout the entire operation process and promptly detect any abnormal objects. For this purpose, we have introduced the R2000https://heiautomation.com/product/ series detection version 2-D LiDARhttps://heiautomation.com/ sensor, which acts as our “eyes” and “tentacles”, providing a solid guarantee for reliable operation.

target

In the actual operational environment, effectively monitoringhttps://heiautomation.com/contact-us/ the surrounding environment and responding to various emergencies is a major challenge. Especially in some complex situations, such as in a multi-level double-decker parking lot or on warehouse shelves with protruding goods, even small suspension belts or protruding items on the shelves can pose safety hazards.Therefore, we urgently need a product that can flexibly handle such complex scenarios. It should have high resolution, capable of accurately capturing those tiny objects; at the same time, it must also have a sufficiently large scanning range to cover a wider monitoring area, thereby ensuring the reliability of obstruction monitoring.

solution

In response to these challenges, the R2000 https://heiautomation.com/about/series test version laser scanner stands out due to its outstanding product performance. Its high angular resolution, wide scanning angle, and long detection range enable it to perform exceptionally well in object scanning and monitoring applications in high-demand areas.After years of market testing, the R2000 series detection version

solution has demonstrated extraordinary strength in the field of obstacle detection.

product superiority

The R2000 sensor adopts an integrated rotating design of the emitter, curved mirror and receiver, based on pulse measurement technology, achieving high-precision and high-speed measurement over a 360° full area. Compared with the traditional rotating mirror design, the R2000https://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6j provides a narrower measurement plane, ensuring the accuracy of the measurement.Furthermore, its simple configuration and extremely high angular resolution

design enable the R2000 detection version to achieve sub-millimeter

target object detection. It is an ideal choice for area monitoring and small object detection.

- Monitoring Area Planning Function

Within the detection range, customers can freely define up to 4 independent monitoring areas to accommodate different equipment states or environmental https://heiautomation.com/product/conditions. - Evaluation of Monitoring Filtering Conditions

When obstacles appear in the monitoring area, the status of the obstacles (such as gaps or obstructions) can be defined, and the minimum size of the obstacles to be filtered can be set. At the same time, by adjusting the multiple evaluation filtering algorithm, unreliable signals can be filtered out to ensure the acquisition of reliable detection signals. - Free Definition Function for Input and Output Signals Users can freely define whether a signal is an input or an output. The input signal can serve as an auxiliary signal to activate the sensor, while the output signal can be associated with the input signal and the planned monitoring area, and combined through logical “AND” or “OR” operations https://studio.youtube.com/channel/UC5jh-_J8N51BACPDqMnnT6Q/videos/short?filter=%5B%5D&sort=%7B%22columnType%22%3A%22date%22%2C%22sortOrder%22%3A%22DESCENDING%22%7Dto meet the requirements of different applications.

product feature

Highlights

Minimum angular resolution: 0.071. Angle step length: 1.24 mm

Maximum detection distance: up to 60m

Maximum scanning rate: up to 30 Hz

4 configurable detection areas

4 configurable input/output switch quantities “interfaces”

P+Fhttps://heiautomation.com/ – A Leader and Innovator in Future Automation

P+F , headquartered in Mannheim, Germany, continuously develops innovative technologies and provides a wide range of products to global factory automation and process industries. It is dedicated to traditional applications in the automation industry as well as future-oriented applications. At the same time, P+F is constantly promoting the development of forward-looking technologies, paving the way for customers to meet the challenges of the upcoming Industry https://www.facebook.com/profile.php?id=1000872916571304.0.