Overview of KEYENCE Sensor Series,KEYENCE https://heiautomation.com/product/offers a diverse portfolio of sensors tailored to various industries and applications. The following aresome of the key series offered by KEYENCE:

1.Laser Sensors

LR-Z Series: These are high-speed, high-accuracy laser displacement sensors designed for non-contactmeasurement of distance, position, and displacement, They feature a compact design and high-speedresponse, suitable for applications requiring precise control and monitoring.LK-G Series: These are laser distance sensors with long-range measurement capabilities, suitable follarge-scale industrial automation and robotics. They offer high accuracy and stability, even in harshenvironments.

2.lmage Sensors

CV Series: These are vision sensors https://heiautomation.com/contact-us/that utilize advanced image processing algorithms to detectmeasure, and inspect objects. They are ideal for applications requiring high precision and reliabilitysuch as automated assembly and quality control.lM Series: These are industrial cameras designed for machine vision systems. They offer highresolution, low noise, and excellent image quality, making them suitable for detailed inspection andmeasurement tasks.

3.Photoelectric Sensors

EE Series: These are compact, high-speed photoelectric sensors suitable for detecting small objects olhigh-speed moving parts. They offer reliable detection and long service life, making them ideal forautomated manufacturing processes.

EX Series: These are fiber-optic sensors that can be customized with various sensing heads and cablesto suit specific application requirements, They are versatile and can be used in a wide range ofindustries.https://heiautomation.com/contact-us/

- Proximity Sensors

lZ Series: These are inductive proximity sensors designed for detecting metallic objects. They offerhigh sensitivity and reliability, suitable for applications in harsh industrial environments.PZ Series: These are capacitive proximity sensors that can detect non-metallic objects, such as plastic,glass, and liquid. They are versatile and can be used in a variety of automation tasks.

5.Pressure Sensors

FP Series: These are pressure sensors designed for measuring fluid pressure in various industrialapplications. They offer high accuracy and stability, suitable for process control and monitoring.AP Series: These are air pressure sensors that can measure differential pressure, gauge pressure, andabsolute pressure. They are commonly used in HVAC systems, pneumatic control systems, and otherapplications requiring precise pressure measurement.

6.Temperature Sensors

TH Series: These are temperature sensors designed for measuring ambient temperature in industrialenvironments. They offer high accuracy and reliability, suitable for monitoring and controllingtemperature-sensitive processes.

IR Series: These are infrared temperature sensors that can measure surface temperature withoutcontact, They are ideal for applications where direct contact with the measured obiect is not possibleor desirable.

Advantages of KEYENCE Sensors

KEYENCE sensors are renowned for their exceptional performance and reliability, which can be attributed toseveral key advantages:

- High Accuracy and Precision KEYENCE sensors are designed to offer high accuracy and precision,making them suitable for applications requiring detailed measurement and inspection. This is achievedthrough advanced design and manufacturing techniques, as well as rigorous testing and calibrationprocesses.https://heiautomation.com/about/

- High Speed and Responsiveness KEYENCE sensors are capable of operating at high speeds and offeringfast response times, making them ideal for automated manufacturing processes and other applicationsrequiring real-time monitoring and control.

- Versatility and Customizability KEYENCE sensors are versatile and can be customized to suit specificapplication requirements. This includes options for different sensing ranges, sensing methods, and outputsignals, as well as the ability to integrate sensors with other KEYENCE products and systems.Durability and Reliability KEYENCE sensors are designed to withstand harsh industrial environments,including exposure to dust, dirt, moisture, and temperature extremes. They offer long service life and lowmaintenance requirements, reducing downtime and maintenance costs.

- Ease of Use and integration KEYENCE sensors are designed for ease of use and integration into existingsystems. They feature intuitive user interfaces and straightforward setup processes, making themaccessible to a wide range of users, including those with limited technical expertise

Industries of Applicationhttps://heiautomation.com/product/

KEYENCE sensors are used in a wide range of industries, including:Automotive KEYENCE sensors are widely used in automotive manufacturing for tasks such as automatedassembly, quality control, and process monitoring. They help to improve production efficiency, reducedefects, and ensure compliance with stringent quality standards

Electronics in the electronics industry, KEYENCE sensors are used for tasks such as component inspectionassembly verification, and automated testing. They offer high accuracy and precision, making them ideafor applications involving small, delicate components.

Semiconductor KEYENCE sensors are used in semiconductor manufacturing for tasks such as wafelinspection, alignment, and etch depth measurement. They offer high resolution and sensitivity, makincthem essential for ensuring the quality and reliability of semiconductor devices.

- Food and Beverage In the food and beverage industry, KEYENCE sensors are used for tasks such aspackage inspection, fill level detection, and temperature monitoring. They help to ensure product safetyreduce waste, and improve production efficiency.

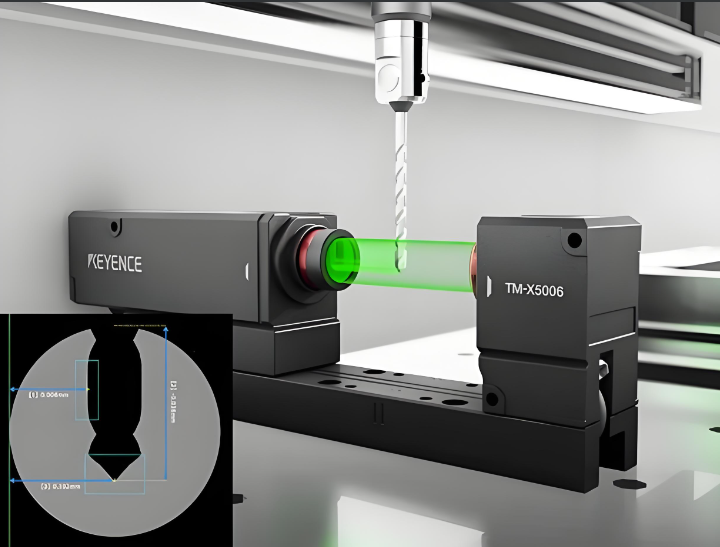

- Packaging KEYENCE sensors are widely used in packaging machinery for tasks such as product detectionalignment, and conveyor control. They vial offer inspection high, speed and and packaging reliabilityverification,. making They them help ideal to for ensure automated compliance packaging with linesregulatory, requirements and improve6 production. efficiency **,Ph armaceutical 7 . ** InMlachine theTool pharmaceutical industry , KEY KEYENCEENCE sensors sensors are are used used for in tasks machinesuch tool as applications pill for counting tasks, such as tool wear detection, position feedback, andprocess monitoring. They offer high accuracy and reliability, making them essential for ensuring theprecision and reliability of machined parts.Aerospace ln the aerospace industry, KEYENCE sensors are used for tasks such as component inspection,alignment, and assembly verification. They offer high resolution and sensitivity, making them ideal forapplications involving complex and precision-critical components.

Detailed Analysis of Key Applications

Automotive Manufacturing

In automotive manufacturing, KEYENCE https://heiautomation.com/contact-us/sensors are used in various stages of the production process,including:

Automated Assembly: KEYENCE sensors are used to detect and position components during automatedassembly processes. They help to ensure precise alignment and assembly of parts, reducing defects andimproving production efficiency.

Quality Control: KEYENCE sensors are used for inspecting the quality of automotive components, such asengine parts, transmissions, and body panels. They detect defects such as cracks, scratches, and missingparts, ensuring that only high-quality components are used in production.

Process Mlonitoring: KEYENCE sensors are used to monitor various process parameters during automotivemanufacturing, such as temperature, pressure, and fluid levels, They help to ensure that processes areoperating within specified ranges, reducing the risk of equipment failure and production downtime.

Electronics Manufacturing

In electronics manufacturing, KEYENCE sensors are used for tasks such as:Component inspection: KEYENCE sensors are used to inspect electronic components for defects such ascracks, scratches, and missing parts. They offer high accuracy and precision, making them ideal forapplications involving small, delicate components.Assembly Verification: KEYENCE sensors are used to verify the correct assembly of electronic devicessuch as smartphones, tablets, and computers. They detect any deviations from the specified assemblyprocess, ensuring that only high-quality products are shipped to customers.Automated Testing: KEYENCE sensors are used in automated testing systems to measure the performanceof electronic devices, such as battery life, signal strength, and data transfer rates. They help to ensure thatdevices meet specified performance standards, improving customer satisfaction and reducing product

returns.

Semiconductor Manufacturing

In semiconductor manufacturing, KEYENCE sensors are used for tasks such as:Wafer lnspection: KEYENCE sensors are used to inspect wafers for defects such as particles, scratches, andcracks. They offer high resolution and sensitivity, making them essential for ensuring the quality and

reliability of semiconductor devices.

Alignment: KEYENCE sensors are used to align wafers and other components during the semiconductormanufacturing process. They ensure precise alignment of parts, reducing the risk of defects and improvingproduction efficiency.

Etch Depth Measurement: KEYENCE sensors are used to measure the depth of etches on semiconductorwafers. They offer high accuracy and precision, making them ideal for applications requiring detailedmeasurement and inspection.

Food and Beverage ManufacturingIn food and beverage manufacturing, https://heiautomation.com/about/KEYENCE sensors are used for tasks such as:Package Inspection: KEYENCE sensors are used to inspect packages for defects such as tears, leaks, anomissing labels. They help to ensure that only high-quality products are shipped to customers, reducingproduct returns and improving customer satisfaction.Fill Level Detection: KEYENCE sensors are used to detect the fill level of containers during the packagingprocess. They ensure that products are filled to the correct level, reducing waste and improving productionefficiency.