There are many machininghttps://heiautomation.com/product/ centers in the workshop. At the waste material outlet of each machining center, there is a material box to collect the waste. Employees need to constantly patrol the workshop to check the material level in each waste material box and replace the full ones with new ones. This patrol work leads to a large workload for the employees and low work efficiency. Sometimes, the waste material may overflow and spill during transportation.

application requirement

Real-time detection of the materialhttps://heiautomation.com/ level in the waste bin is carried out. When the bin is about to be full, a signal is given. The equipment alarm will prompt the staff to replace the new bin through sound and light alarms.

Application challenges

The waste materials in the bin are in the form of powders and sheet-like metallic residues. Some of them have a strong reflective property. The waste residues naturally form a conical surface within the bin.

Bannerhttps://heiautomation.com/contact-us/ Solution

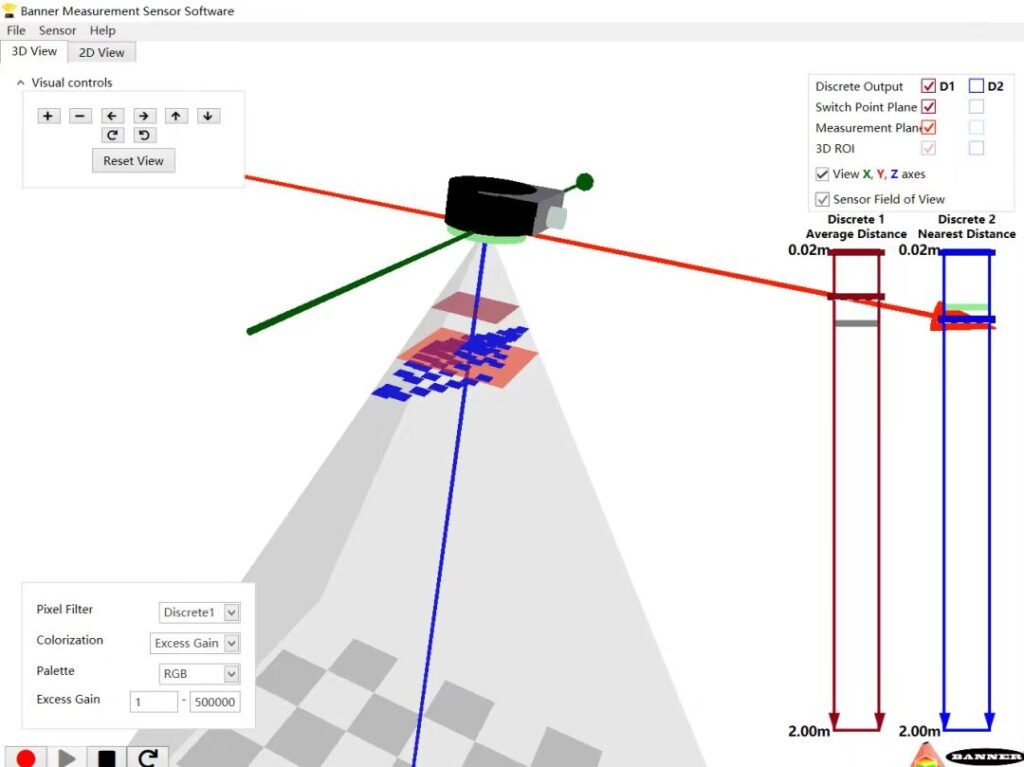

Use the Banner K50Z-FA2000KD-Q8 https://heiautomation.com/about/multi-point measurement sensor for sweetness measurement.

Application of the plan

- Install the sensor

Connect the software, set the average distance within the detection area, and set 2

Set the data range of the average distance for the output switch quantity signal;

Set a slow response speed, a slightlyhttps://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6j larger hysteresis, and on-delay/off-delay to stabilize the output signal.

Disconnect the software connection and the debugging cable, and the equipment operates normally.

Why Banner?

The K50Zhttps://www.youtube.com/@%E6%9B%BE%E6%85%A7%E5%A9%B7-z6j multi-point sensor can detect the overall filling condition of the material in the bin. It will not be affected by the high or low level in a small area or the interference of reflections in the overall detection result.

The K50Z has a compact design, is easy to install, and offers high cost-effectiveness.

Customer benefits

It can detect the overall filling condition of the material in the bin.

It reduces the workloadhttps://studio.youtube.com/channel/UC5jh-_J8N51BACPDqMnnT6Q/videos/short?filter=%5B%5D&sort=%7B%22columnType%22%3A%22date%22%2C%22sortOrder%22%3A%22DESCENDING%22%7D of the staff, improves work efficiency, and ensures that the bin is replaced in time and prevents waste materials from spilling out.